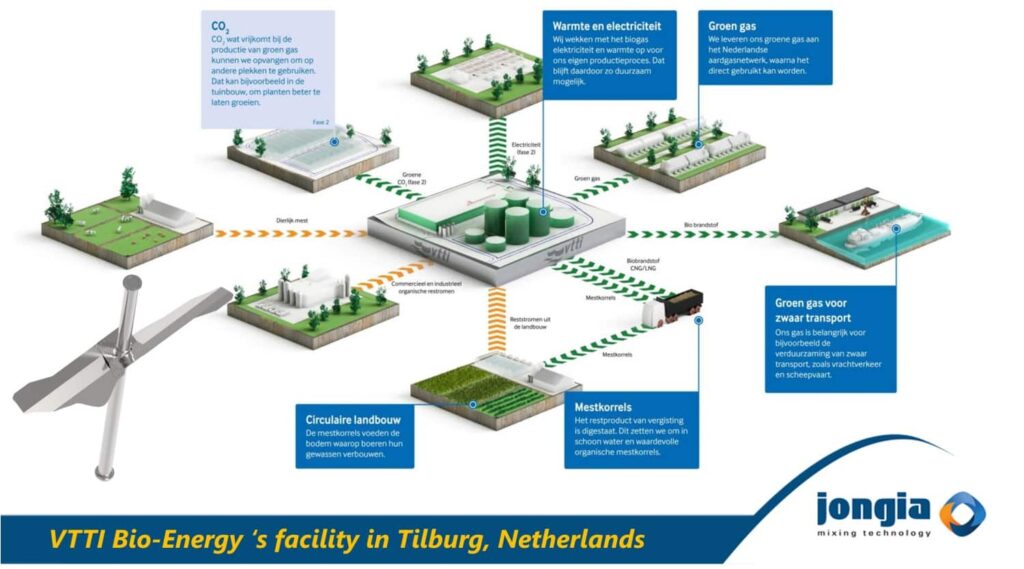

VTTI Biogas Tilburg is developing a new bio-energy facility, focusing on processing organic waste. The plant is expected to produce approximately 23 million cubic metres of biogas annually. A portion of this will be converted into green gas for the Dutch gas grid, which is sufficient to cover the annual gas consumption of about 2,700 households. This contributes to the sustainability of the Netherlands, aligning with the national goal of producing 2 billion cubic metres of green gas by 2030.

Green gas is a clean and sustainable alternative to traditional natural gas. It is produced from 100% natural sources, such as local manure or waste from the food and animal feed industries. This waste is transformed into biogas through fermentation, which, after purification and drying, is made suitable as green gas. Jongia contributes to this with its innovative Biofoil Mixing elements, mounted on the mixers of the four large silos in this installation.

In addition to green gas, the facility also produces organic fertilisers. Approximately 40,000 tonnes of dry organic fertiliser pellets are produced annually, aiding in the recycling of valuable minerals and supporting regenerative agricultural practices. These pellets are particularly useful in areas with mineral deficiencies in the soil, contributing to circular agriculture.

The location in Tilburg has been strategically chosen close to the source of the raw materials, reducing transport and greenhouse gas emissions. According to Wageningen University, the arrival of this facility could reduce CO2 emissions by about 60,000 tonnes annually, equivalent to the emissions of 3,000 households. The facility also generates its own electricity and heat from the biogas, which is used for various production processes.

VTTI Biogas Tilburg is also involved in the development of other bio-based innovations and products, such as bio-LNG for transport and CO2 capture for use in horticulture or for the production of bio-based materials. A part of this innovation is the use of Jongia’s Biofoil Mixing Element in their biogas silos.

Read more information about Jongia’s experience in the Biogas Industry.

Biogas

Biogas Agitators, mixers and mixing elements for Biogas Industry Small, medium or large capacity tanks used in the Renewable Energy industry such as for digesters require tailor made agitators to mix, keep the content homogeneous, prevent floating layer/foam and minimize

BioFoil® Mixing Element

Tutorial Biofoil

To understand how this unique mixing element works we have created a tutorial. Sales Director Tom Pruymboom explains.

Contact our specialized team for all your questions

Tom Pruymboom

Sales Director

Area Worldwide

Bart Brouwer

Area Sales Manager

Area Worldwide

Biofoil Articles

VVTI Biogas Tilburg

VTTI Biogas Tilburg is developing a new bio-energy facility, focusing on processing organic waste. The plant is expected to produce approximately 23 million cubic metres of biogas annually. A portion of this will be converted into green gas for the

Tutorial: How does the BioFoil® propeller work?

The BioFoil® propeller is not just any propeller. It is Jongia Mixing Technology’s own design for the Biogas market. In the Biogas process gas is generated and disposed of from a tank filled with liquid (digestate). Recently, this technique has

The development of a proprietary biogas agitator

Jongia Mixing Technology has been active in the biogas market since 2008. In the process regarding biogas, gas is generated and disposed of from a tank filled with fluid (digestate). This digestate mainly consists of organic waste. Over the last