Products

Jongia Mixing Technology – We understand your process

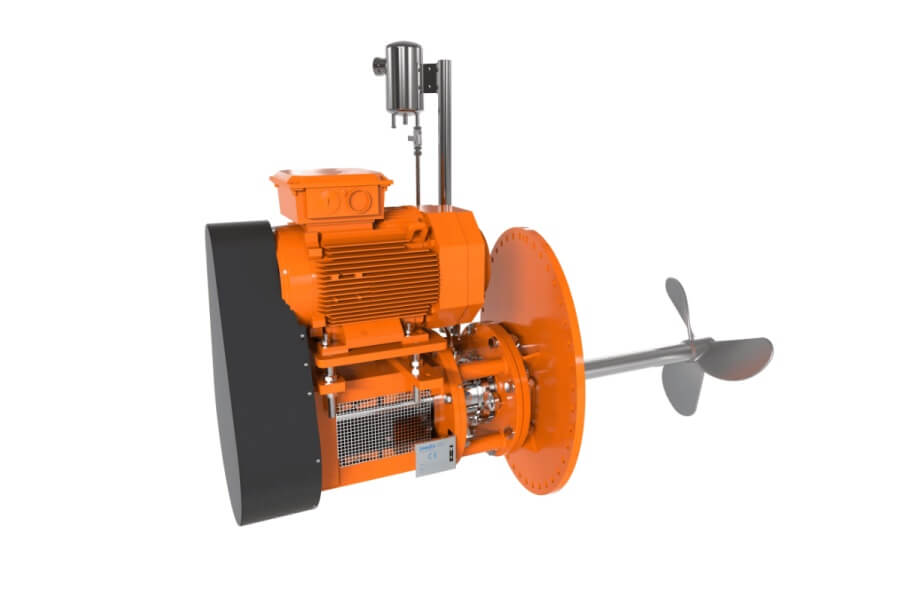

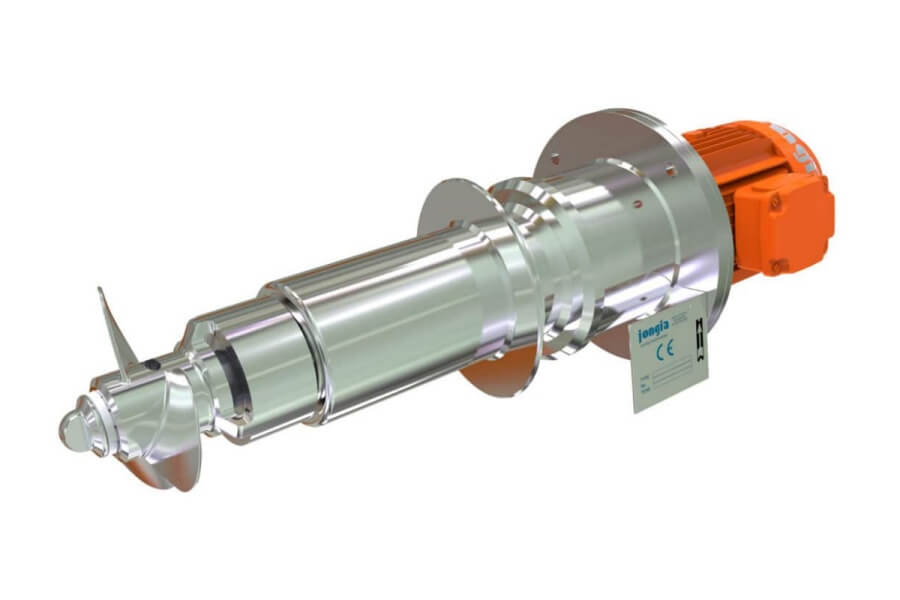

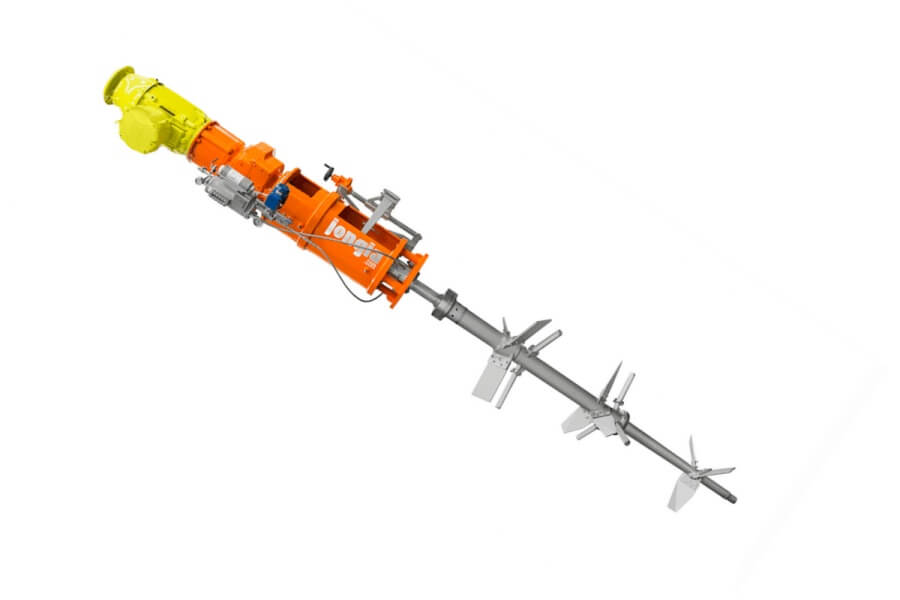

Jongia has a comprehensive range of stirring and mixing equipment, products and systems. We ensure the best possible solution for the given process, choosing from our wide range of agitators and mixers. We offer top, side and bottom entry agitators, special designs like magnetic mixers, as well as dynamic and static in-line mixers and powder dissolving installations. Characteristics of our mixing equipment and products are: High quality, Durability, Environmentally friendly, Low maintenance. Depending on the application we divided our top, side and bottom entry agitator types into 3 levels: light, medium and heavy duty.

Top-Entry Agitators

Side-Entry Agitators

Bottom-Entry Agitators

Specials Agitators

Frequently Asked Questions

What types of agitators does Jongia offer?

Jongia offers a comprehensive range of stirring and mixing equipment, including top, side, and bottom entry agitators, as well as special designs like magnetic mixers, and dynamic and static in-line mixers. The equipment is categorized into light, medium, and heavy duty based on application.

What are the key characteristics of Jongia's mixing equipment?

Jongia’s mixing equipment is known for its high quality, durability, environmentally friendly design, and low maintenance requirements. These attributes ensure effective mixing solutions tailored to various processes, enhancing overall productivity.

Can I find customized mixing solutions?

Jongia specializes in providing customized mixing solutions tailored to specific production processes. Our extensive range of agitators and mixers allows for flexible options to meet unique application needs. Contact us to discuss your requirements.

Where can I learn more about different agitator types?

Detailed information about different agitator types, including light, medium, and heavy duty options, can be found on Jongia’s website. Each type is designed for specific applications and operational requirements, offering various benefits to enhance mixing efficiency.

Are Jongia products suitable for all industries?

Jongia’s stirring and mixing equipment is widely applicable across multiple industries, including food, pharmaceutical, and chemical processing. Our focus on quality and durability makes their products effective for various mixing needs, ensuring reliable operation in different environments.

Challenge us to improve your process

Contact us today to learn more about our extensive range and how we can assist you with customized mixing solutions to elevate your production process.

Tom Pruymboom

Sales Director

Area Worldwide

Bart Brouwer

Area Sales Manager

Area Worldwide

Popular Articles

Do I need a Bottom Bearing for my agitator?

Do I need a Bottom Bearing? The installation of a bottom bearing is not mandatory. While it offers certain advantages, there are also drawbacks to consider. It is important to note that the bottom bearing functions more as a displacement

Fermentation & Bioreactor Mixing Process

Bioreactors and Fermenters are culture systems to produce cells or organisms. They are used in various applications, including basic research and development, and the manufacturing of biopharmaceuticals, food and food additives, chemicals, and other products. A broad range of cell types and organisms can be cultivated in bioreactors and Fermenters, including cells (like mammalian cell lines, insect cells, and stem cells), microorganisms (like bacteria, yeasts, and fungi), as well as plant cells and algae. The words “Bioreactor” and “Fermenter” are basically the same thing.

Biodiesel blending with zero leakage!

Fuel blending is a critical component of biodiesel production. A properly blended fuel can increase energy efficiency, reduce emissions and improve performance. However, it can be difficult to achieve consistent fuel quality during blending due to differences in storage tanks,