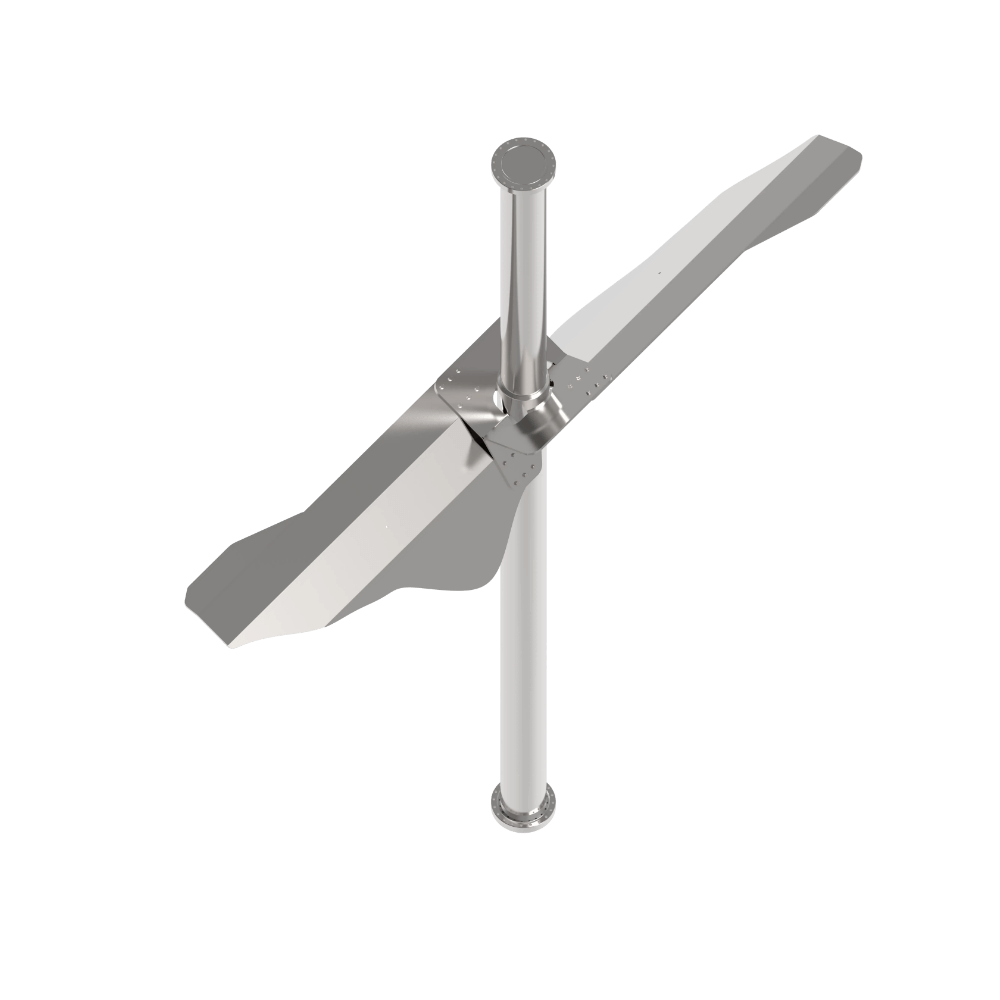

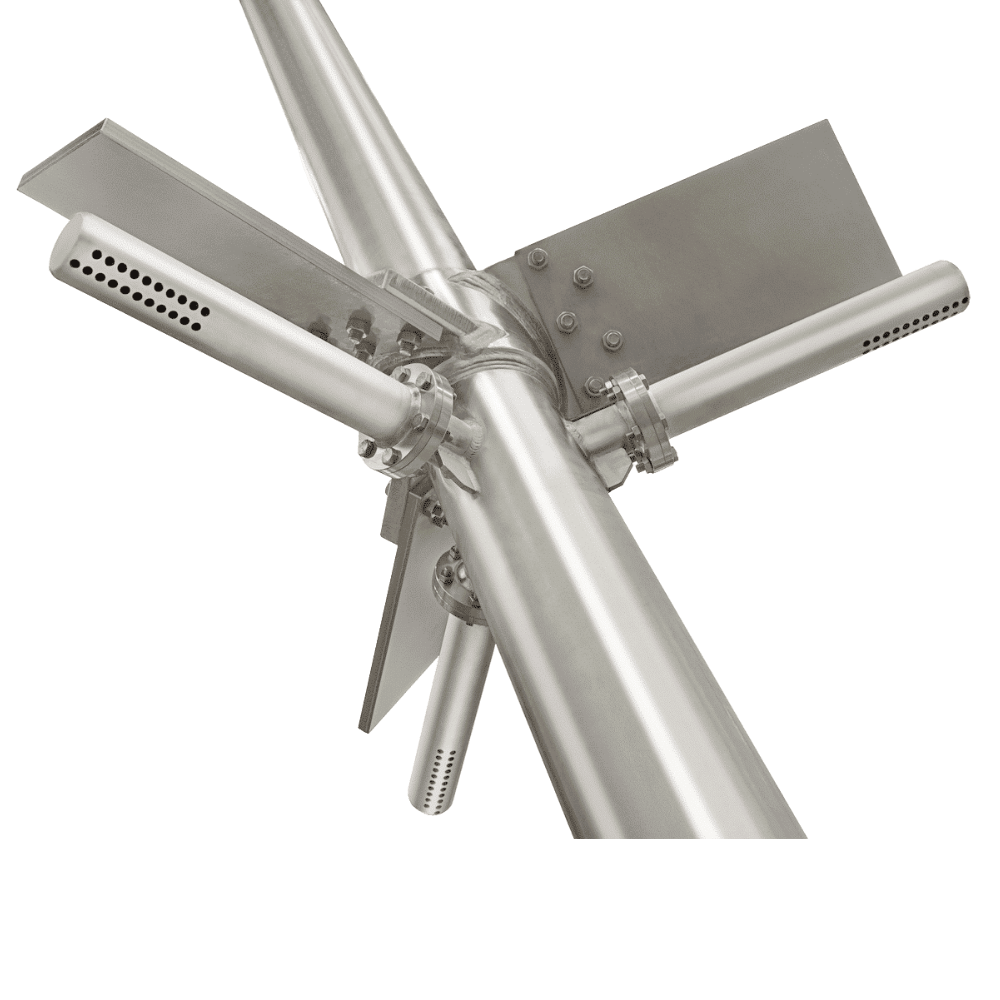

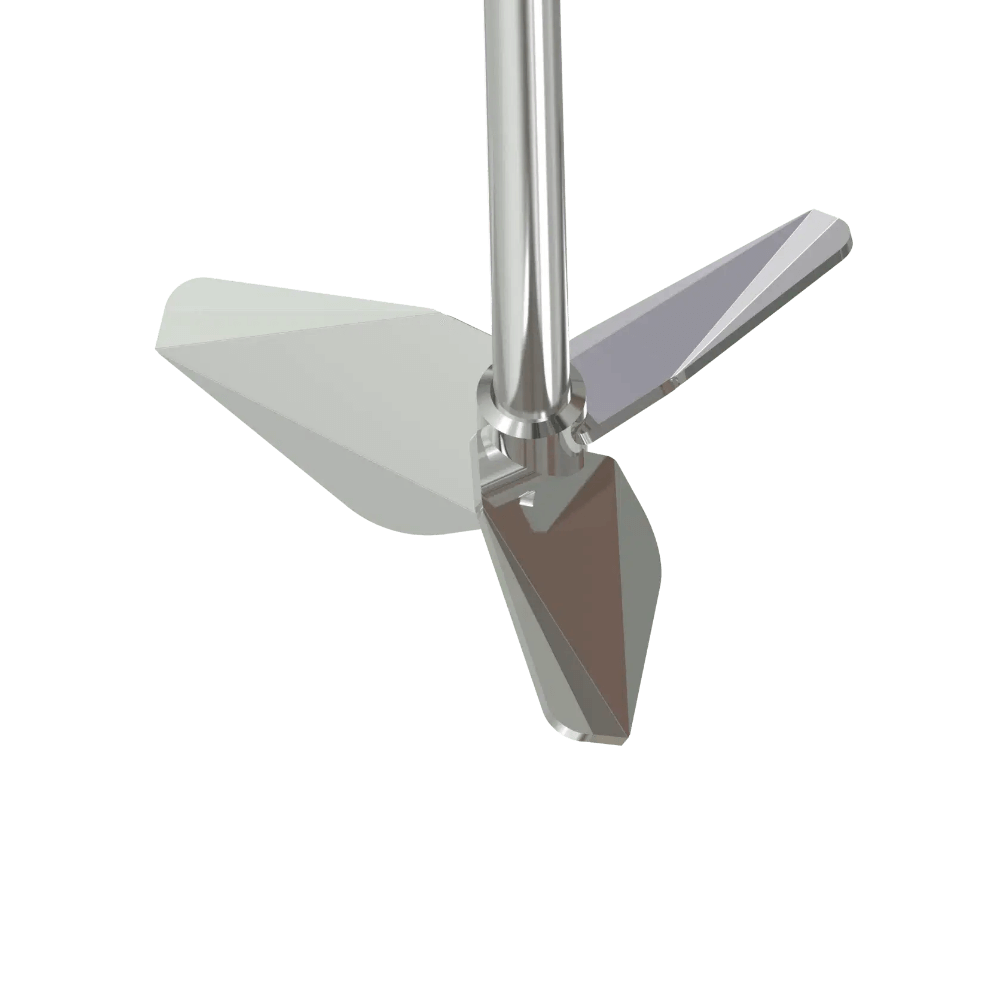

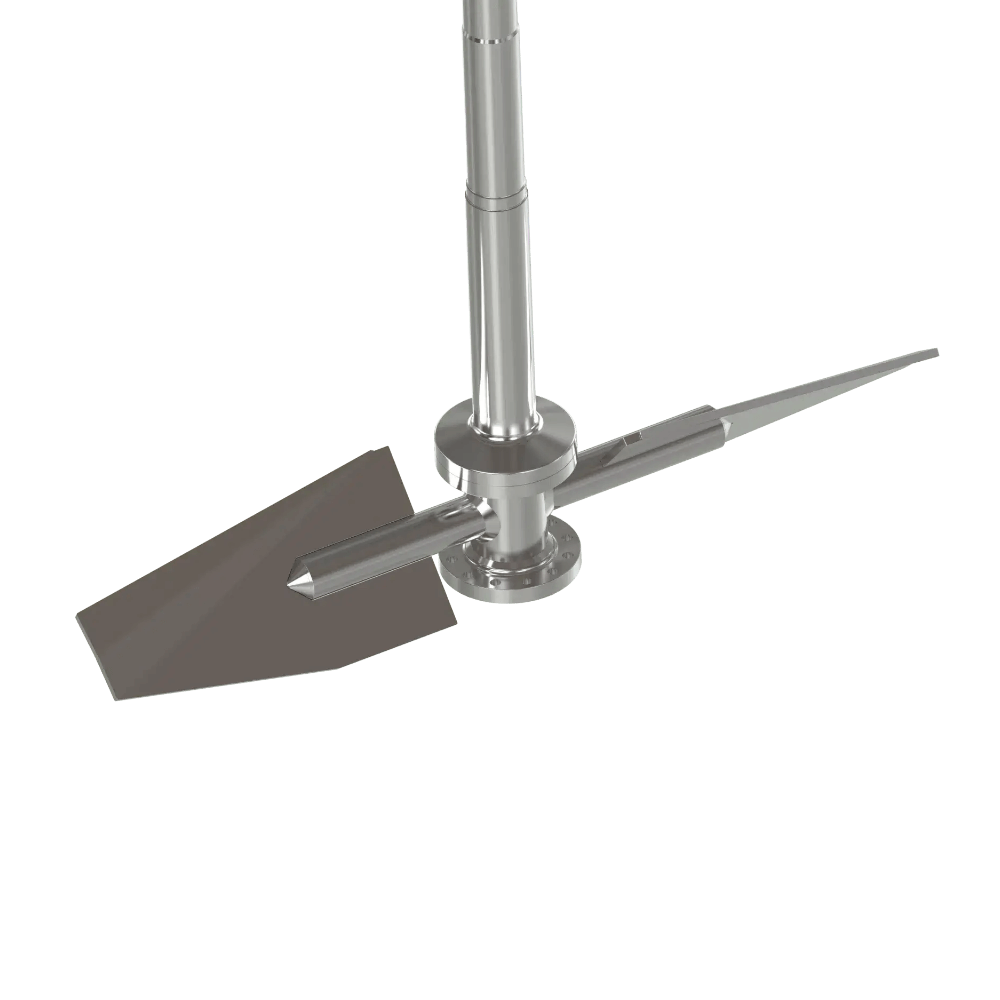

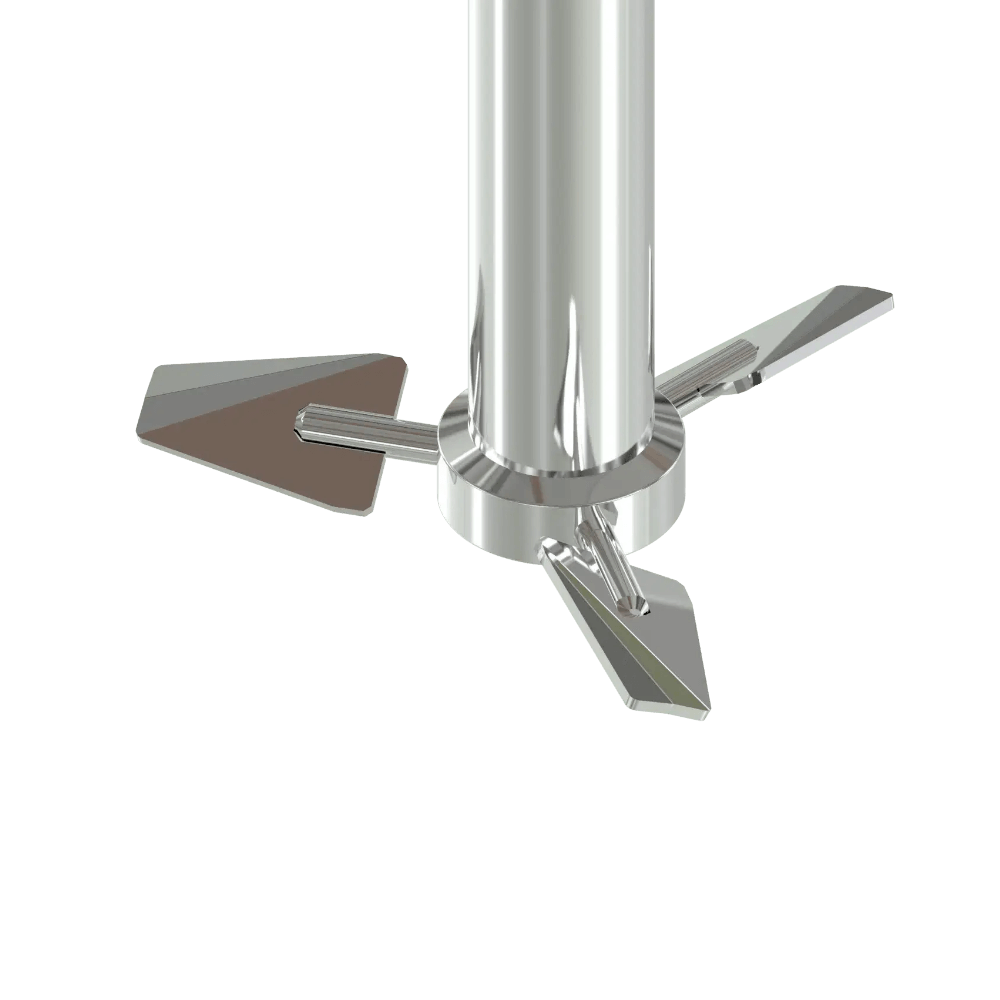

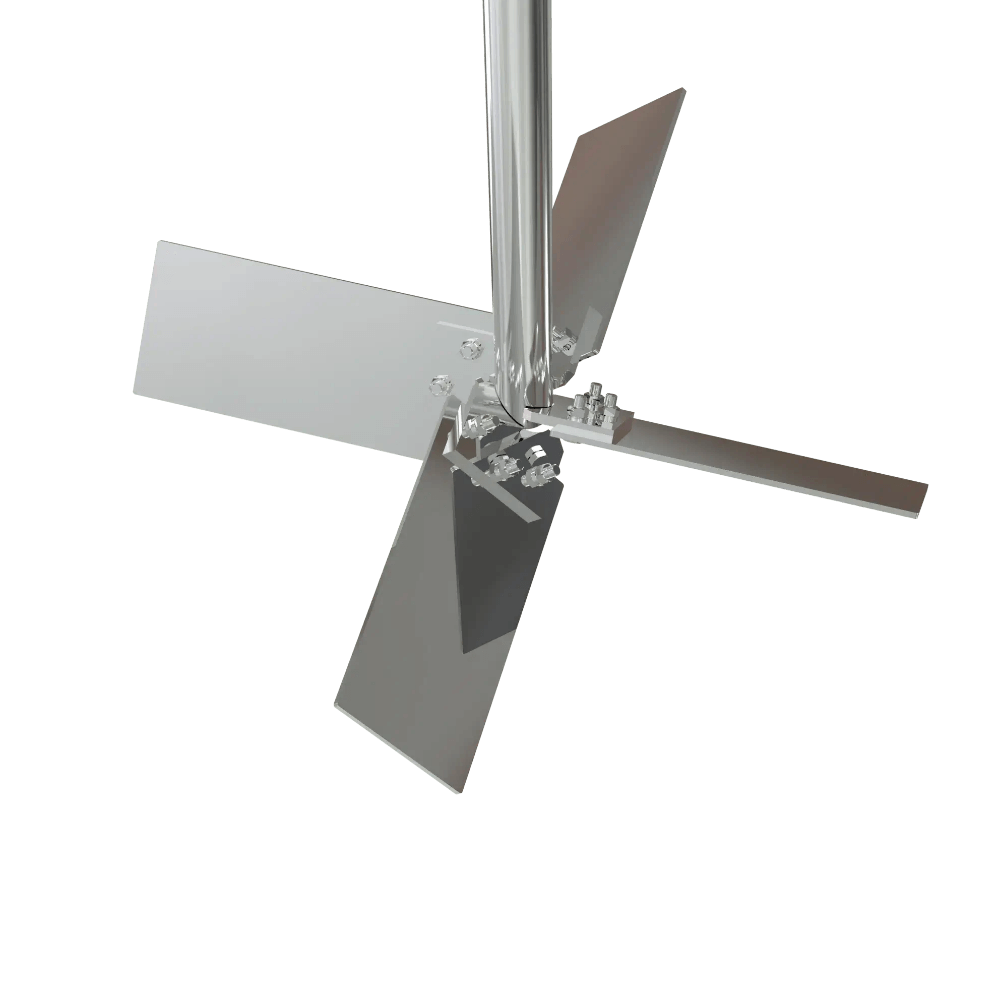

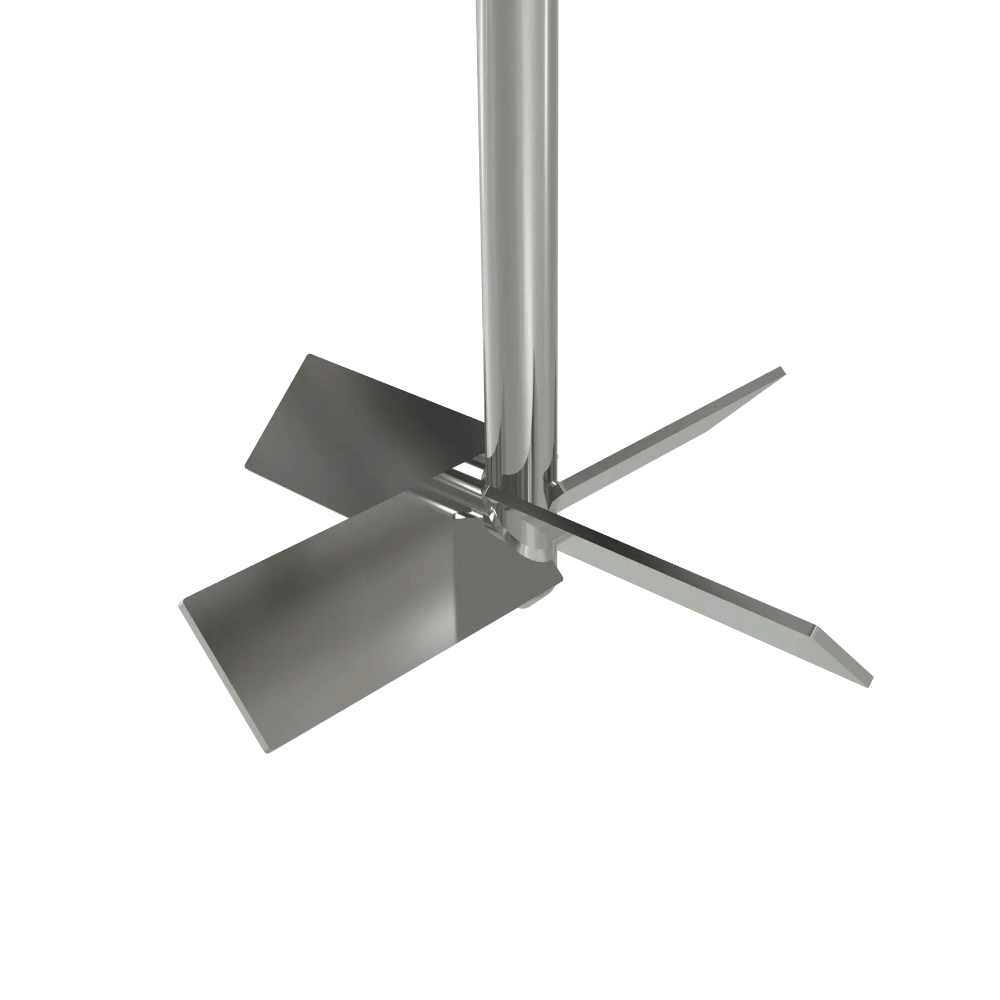

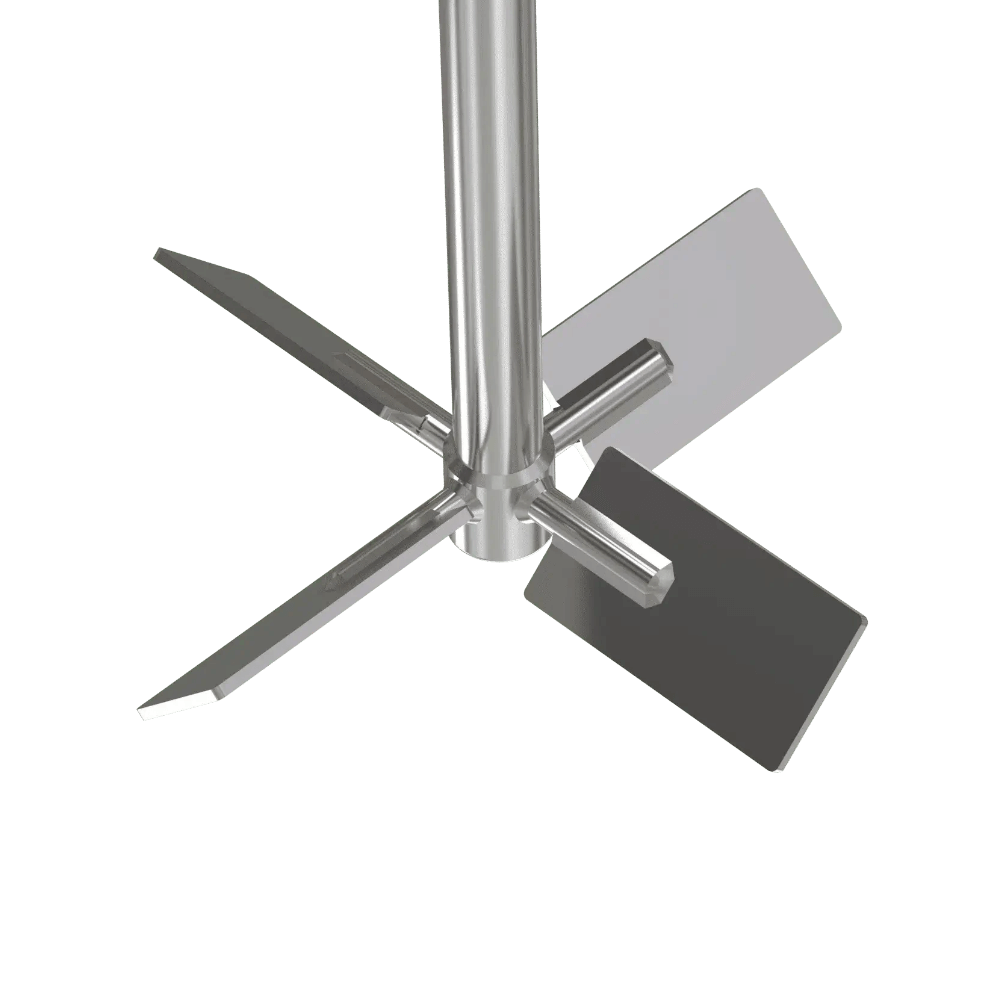

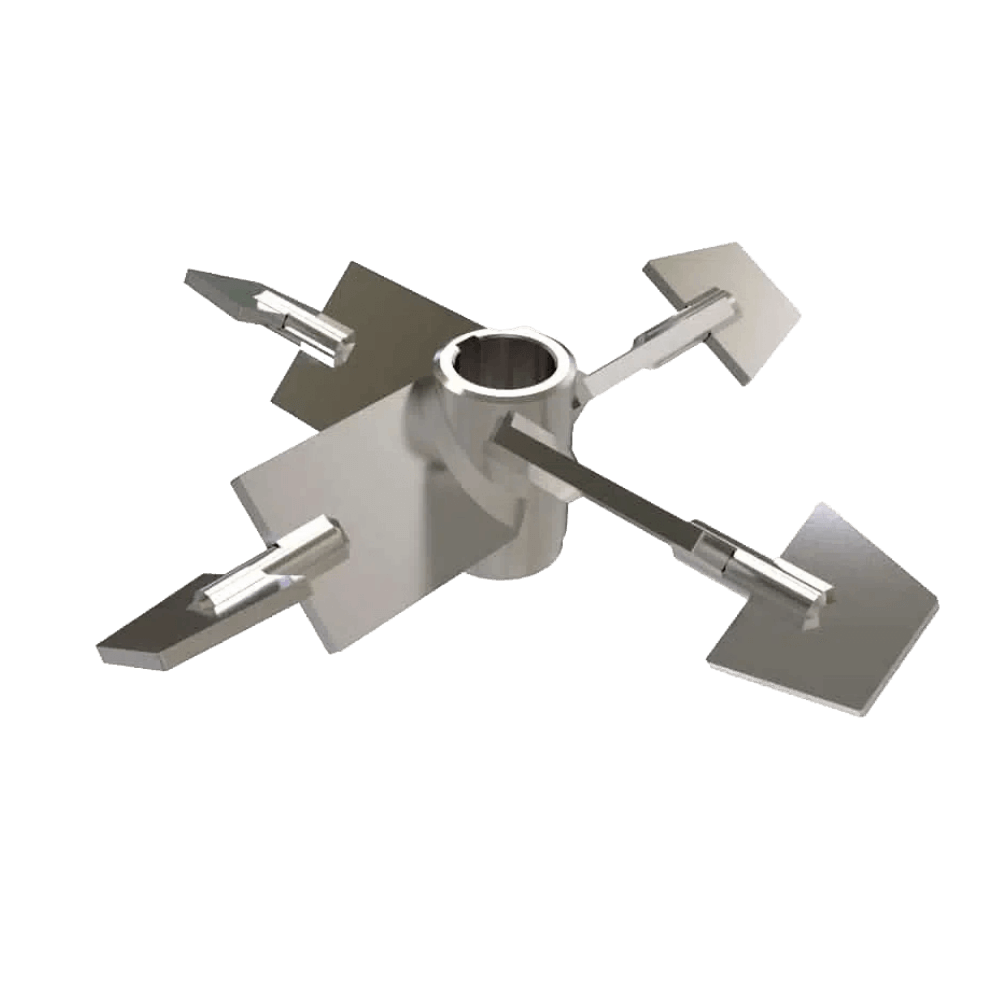

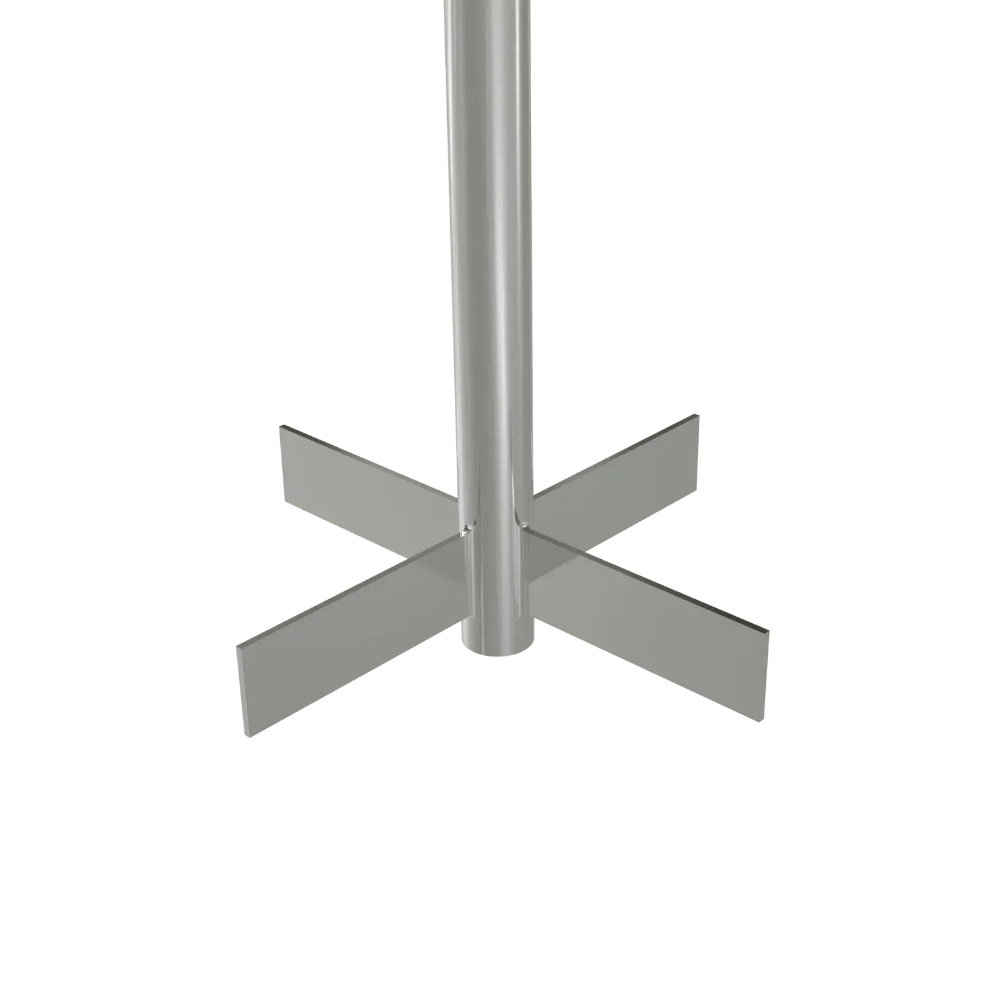

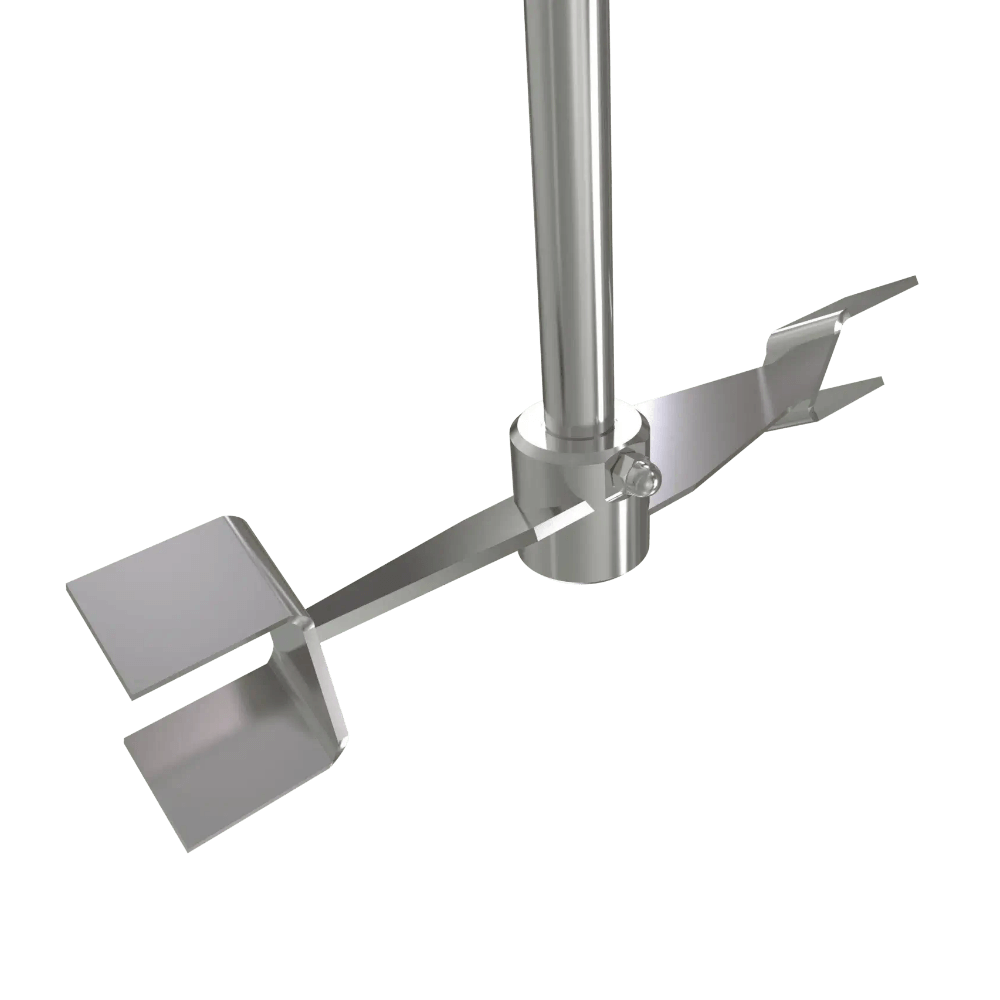

Mixing Elements

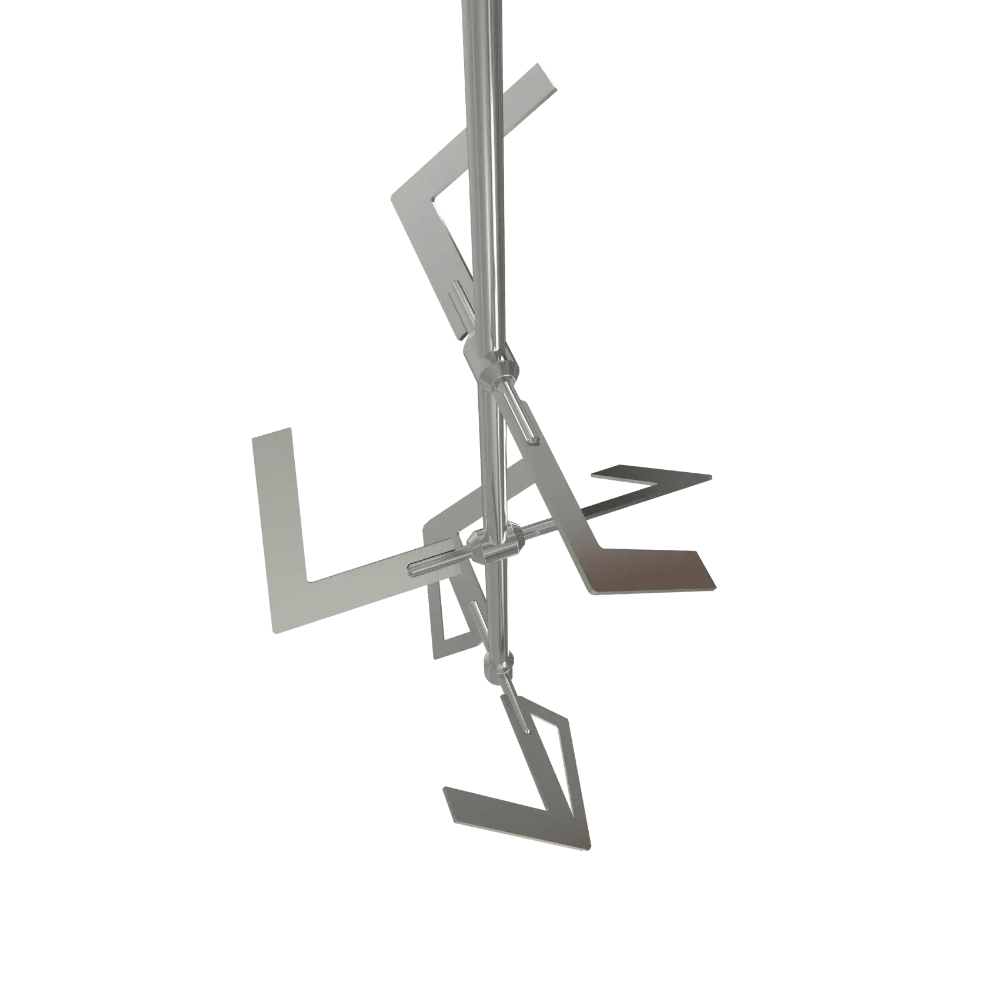

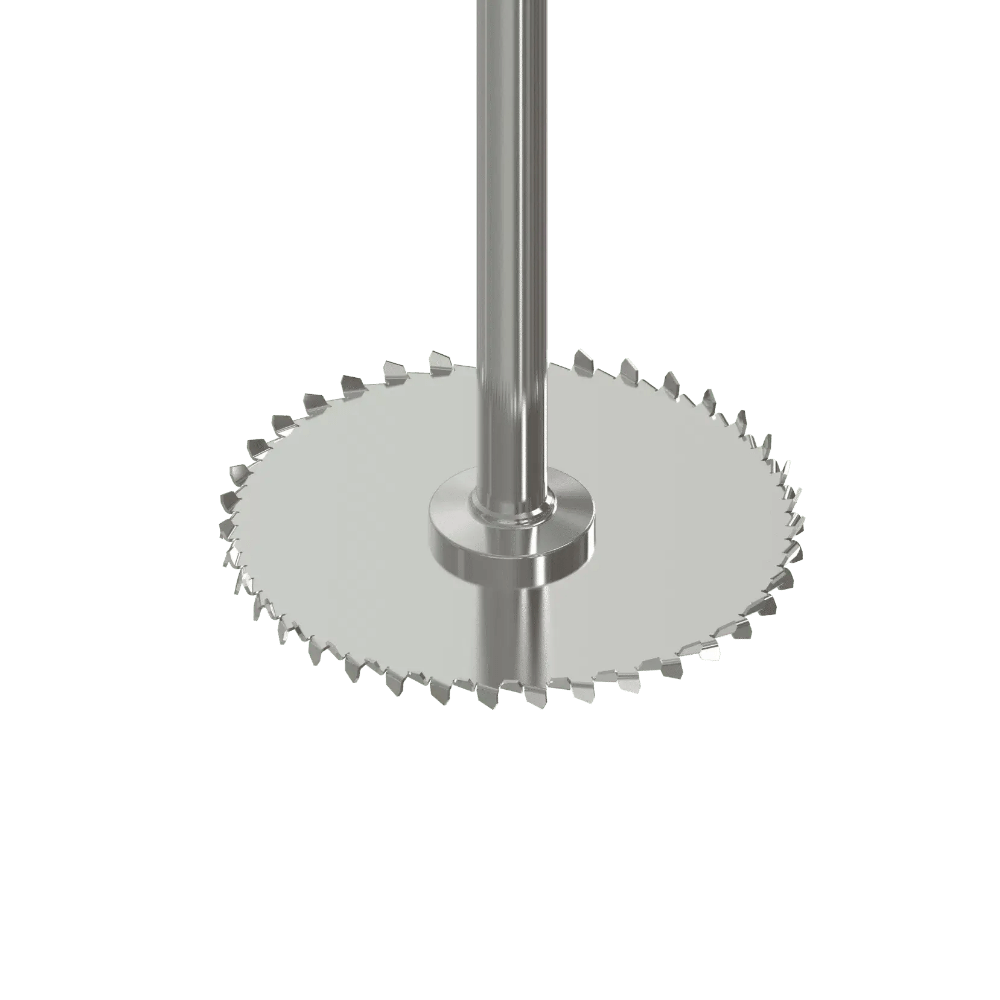

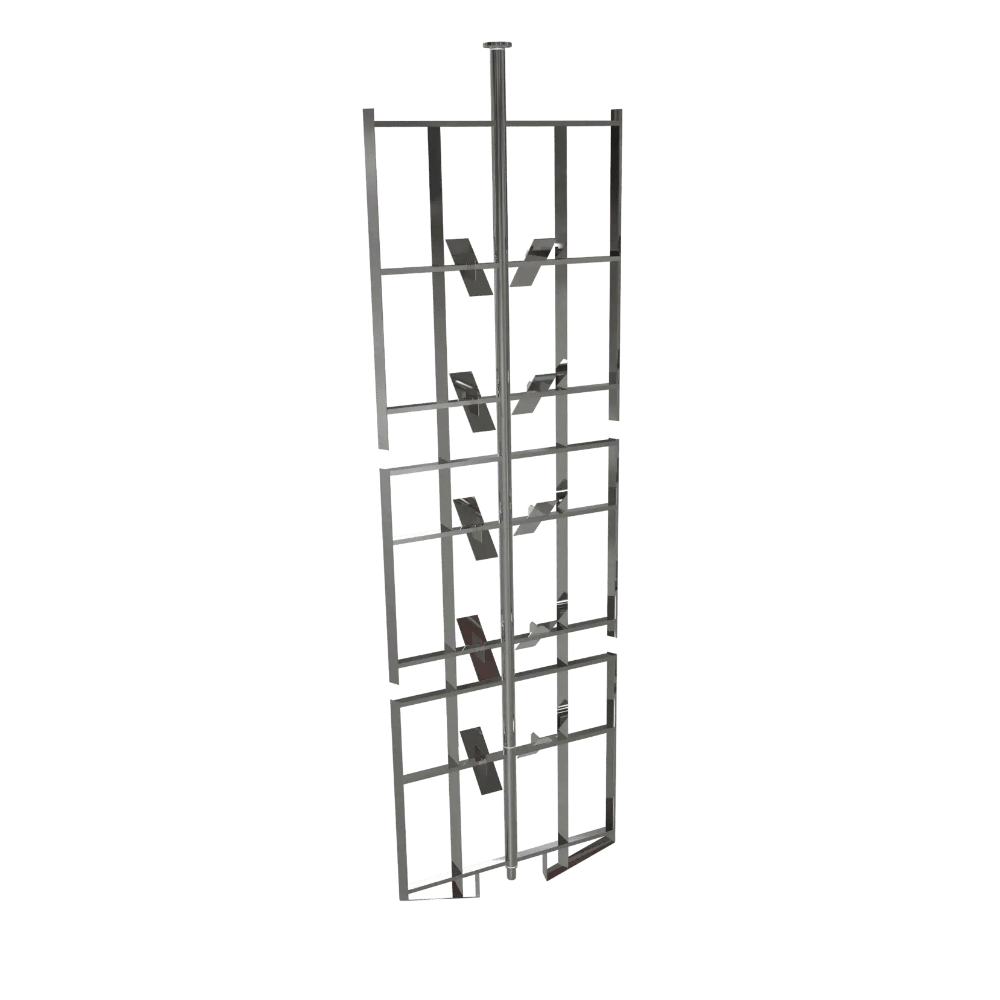

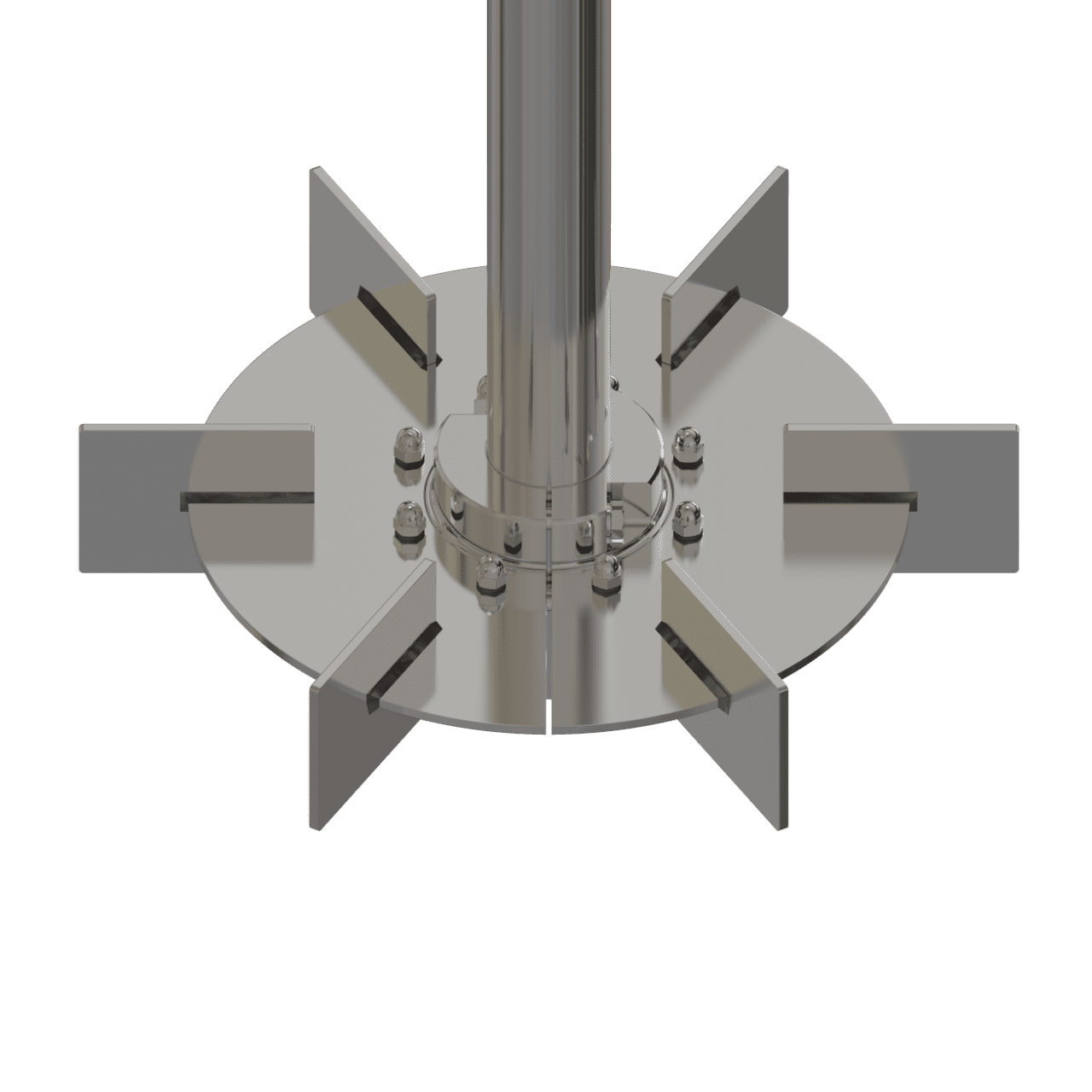

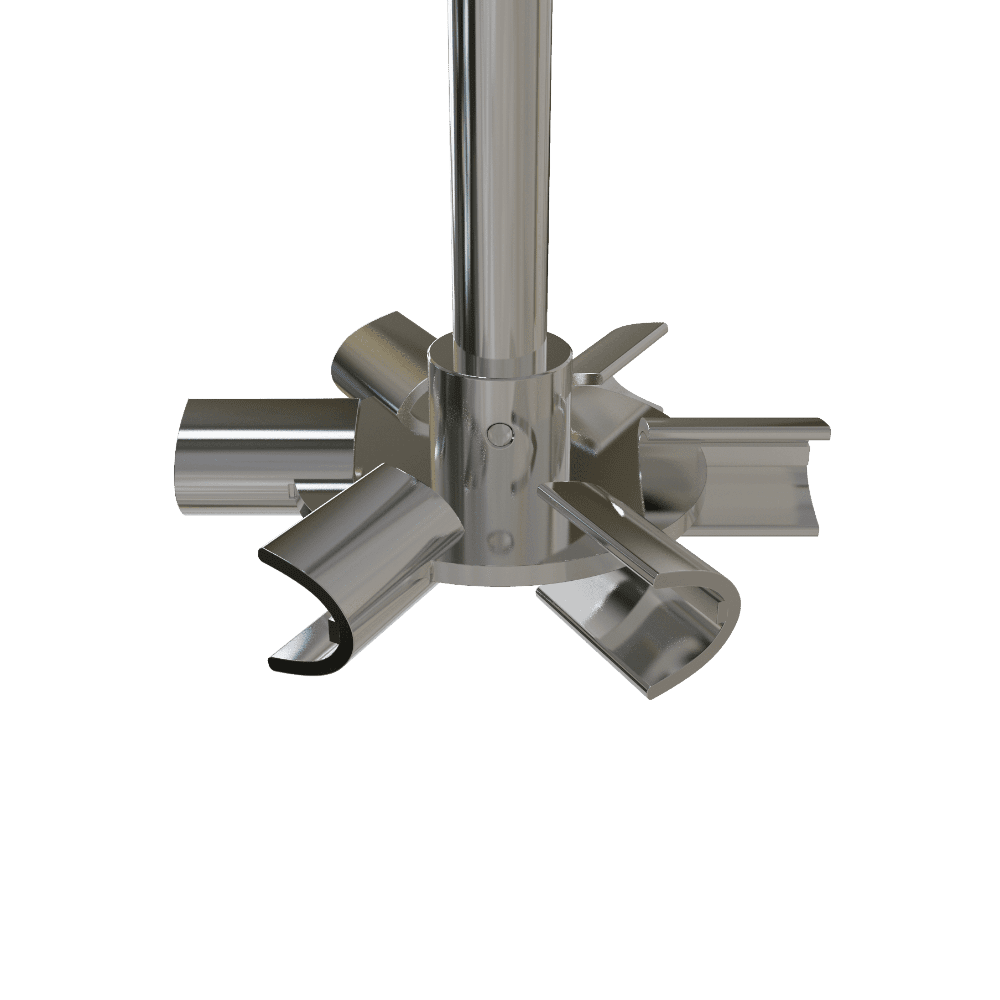

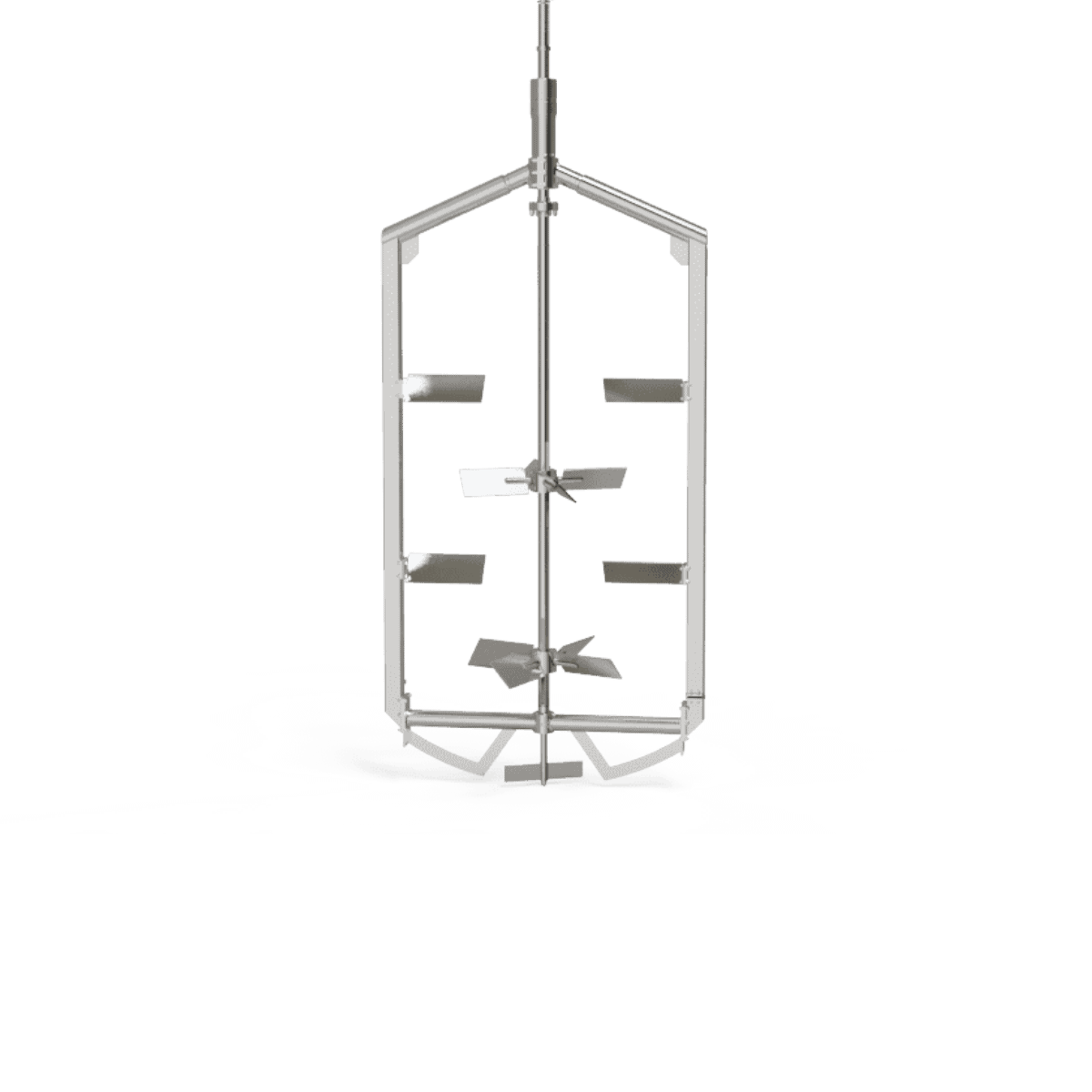

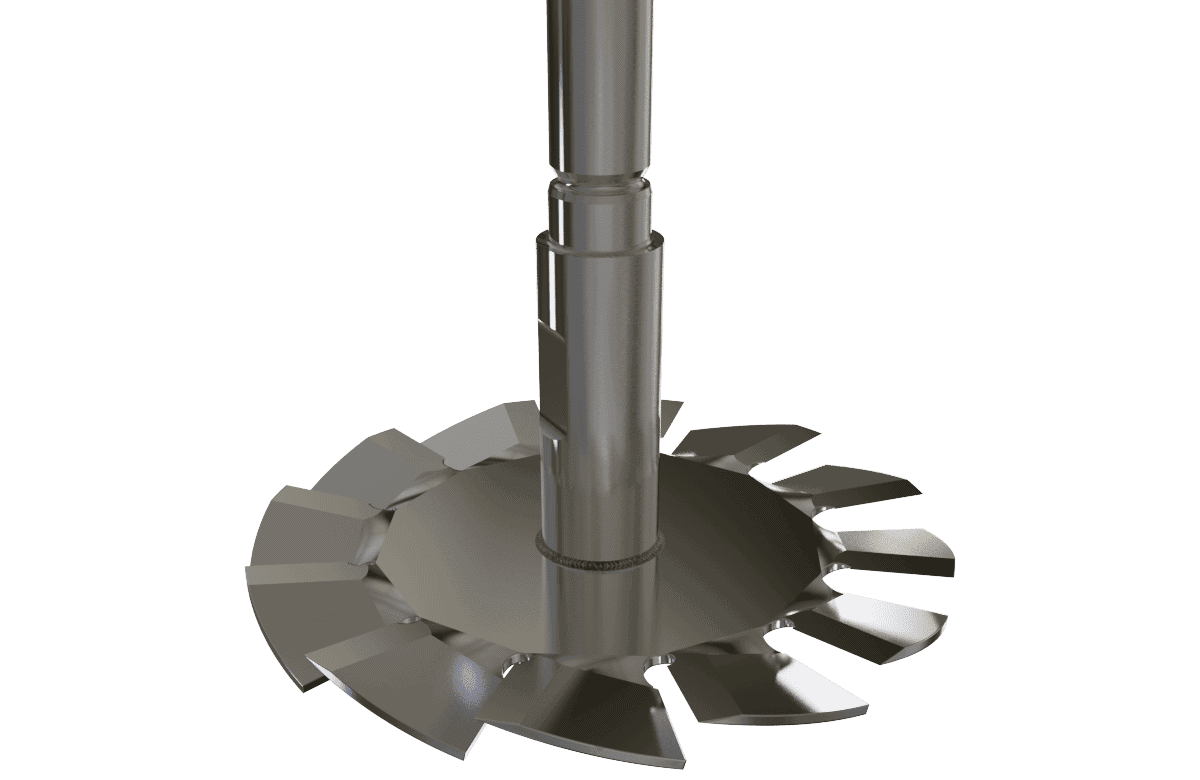

Mixing elements are used in an agitation system to mix or blend fluids, gases or solid materials. Mixing elements are responsible for:

- generating flow patterns, thrust, velocity and turbulence

- ensuring a proper mixing process

Mixing elements are the most important components of which an agitator system is build of. The agitator shaft and drive unit are there to propel the Mixing Element configuration selected for your specific mixing process.

There are a wide variety of Mixing Elements, each with their own performance and applications. Jongia Mixing Technology has developed a complete range of Mixing Elements specifically suitable for your mixing process. Please find out more about each typical characteristics and click on each of the Mixing Elements to receive a full explanatory of each element.

Frequently Asked Questions

What are mixing elements?

Mixing elements are components in an agitation system designed to blend fluids, gases, or solids. They generate flow patterns, thrust, and turbulence, ensuring an effective mixing process essential for various applications.

How do mixing elements contribute to the agitation system?

They are the most vital components of the agitation system. The mixing element configuration selected for a specific process is propelled by the agitator shaft and drive unit, facilitating the desired mixing effects.

What types of mixing elements are available?

Jongia Mixing Technology offers a complete range, each with unique performance characteristics and applications. You can explore various types through our website to find the best fit for your mixing needs.

How can I learn more about specific mixing elements?

For detailed information about each mixing element, please refer to the individual links provided on the Jongia website. Each link leads to a comprehensive explanation of that specific element.

What industries utilize mixing elements?

Mixing elements are widely used in industries such as food and beverages, chemicals, pharmaceuticals, and bio-based applications. These sectors benefit significantly from effective mixing processes for their products.

Contact our specialized team for all your questions

Tom Pruymboom

Sales Director

Area Worldwide

Bart Brouwer

Area Sales Manager

Area Worldwide

Mixing Element Articles

High-Speed Disperser Technology: The Engineering Behind Effective Mixing

A Technical Guide by Jongia Mixing Technology Core Function High-speed dispersers excel at three critical tasks: Fracturing powder agglomerates into fine particles Creating uniform powder distribution throughout liquid mediums Facilitating complete dissolution of soluble materials Operating Principles High-speed dispersers transform

VVTI Biogas Tilburg

VTTI Biogas Tilburg is developing a new bio-energy facility, focusing on processing organic waste. The plant is expected to produce approximately 23 million cubic metres of biogas annually. A portion of this will be converted into green gas for the

Homogenization and Cooling in Diary Cream Production

Utilizing Jongia’s Cup Mixer Homogenization is a standard procedure employed in dairy cream production to ensure the consistent distribution of fat globules in both milk and cream. This process, achieved through a high-pressure homogenization apparatus, breaks down and disperses fat