Industrial Mixers

Jongia Mixing Technology – We understand your process

At Jongia, we understand that a reliable and efficient industrial mixer is crucial to the performance of various industrial processes. Our industrial mixers, designed for both the chemical and pharmaceutical industries, are engineered to meet the highest standards of quality and durability. Whether it’s mixing powders, coating delicate products, or homogenizing viscous substances, our solutions strike the perfect balance between high speed and precision. With years of experience and a wide range of products, we provide the right solution for every specific application. At Jongia, you’ll find premium-quality professional mixers that enhance your production process. In addition to providing top-tier equipment, we offer excellent customer service and technical support to ensure smooth production operations.

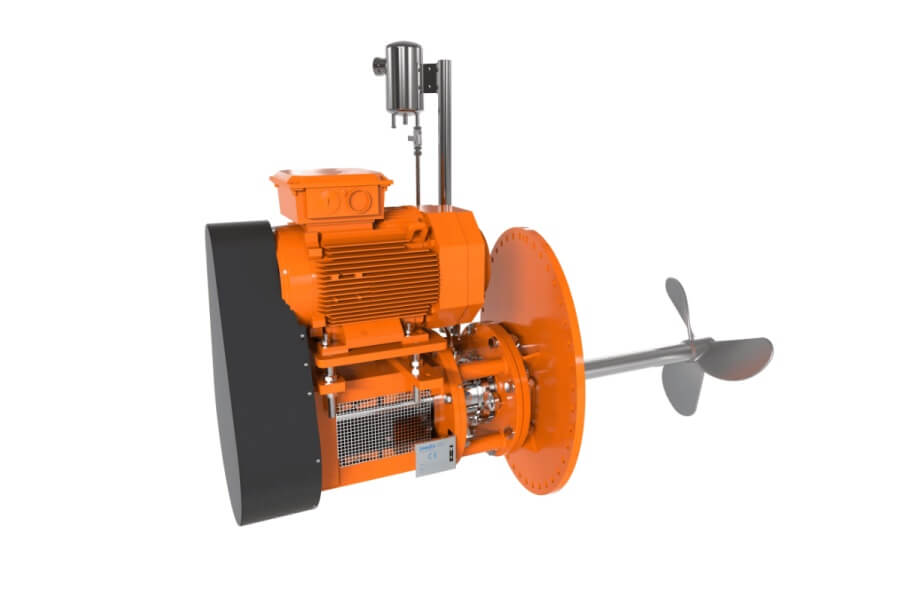

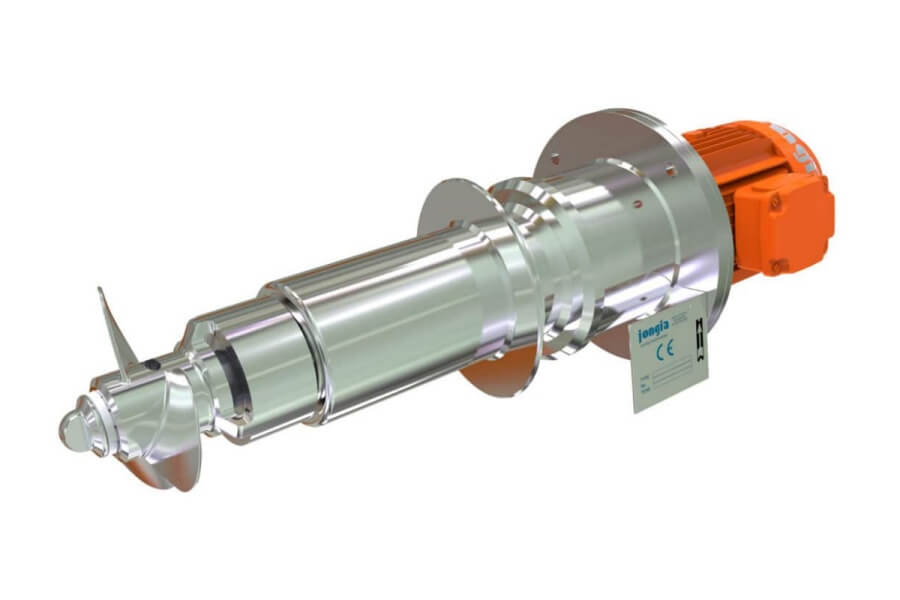

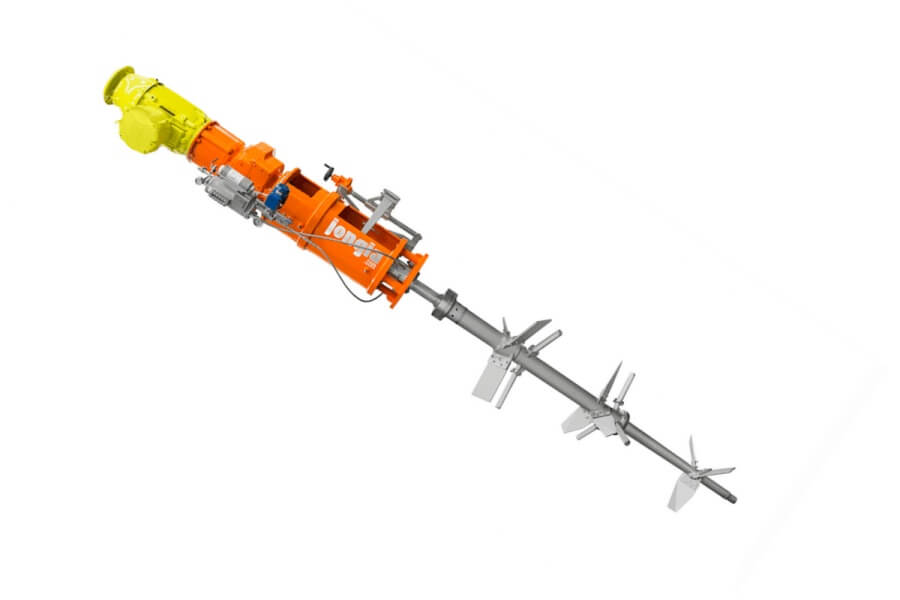

Characteristics of our mixing equipment and products are: High quality, Durability, Environmentally friendly, Low maintenance. Depending on the application we divided our top, side and bottom entry agitator types into 3 levels: light, medium and heavy duty.

Industrial mixers are invaluable in various sectors, from chemical manufacturing to pharmaceuticals. They play a crucial role in uniformly mixing solids, powders, and liquids, essential for producing high-quality end products. At Jongia, we not only offer a broad range of mixers but also provide tailored solutions that meet the specific demands of each industry.

The chemical industry requires highly precise mixing processes where various chemical substances are safely and homogeneously combined. Our industrial mixers are designed for a wide range of applications, including mixing explosive powders and corrosive materials. Jongia offers solutions that withstand harsh conditions, utilizing durable materials and high-quality components. Whether mixing liquid chemicals or coating dry substances, our technology ensures exceptional mixing results with flexibility in speed and precise control.

In the pharmaceutical sector, precision is paramount. Mixing active pharmaceutical ingredients with excipients requires advanced mixing solutions to ensure consistency and homogeneity. Jongia provides an extensive selection of professional mixers specifically designed for these delicate processes. Our solutions, such as the Dynamic series, ensure the processing of sensitive products like pharmaceutical ingredients with minimal risk of contamination and maximum hygiene.

At Jongia, we offer a comprehensive range of mixing equipment, suitable for both small-scale and large-scale applications. Our portfolio includes everything from mobile mixers to large industrial mixers designed for demanding applications. Each product is made from premium materials and engineered to withstand intensive use in various conditions.

Jongia is committed to technological innovation and creative solutions to ensure our mixers meet the evolving demands of the market. Our conical mixers and side-entry mixers, for example, are ideal for specific applications requiring premium product quality. With our focus on continuous innovation, we offer mixers with variable speeds and customization options tailored to the specific needs of your industry.

Along with our high-quality products, we provide outstanding customer service and comprehensive technical support. Our team of experts is available to assist you in selecting the right mixer for your specific process, as well as offering maintenance and spare parts supply.

Top-Entry Agitators

Side-Entry Agitators

Bottom-Entry Agitators

Specials Agitators

Frequently Asked Questions About Industrial Mixers

An industrial mixer is a device used to uniformly mix solids, powders, and liquids for a wide range of industrial applications, such as in the pharmaceutical and chemical industries.

In the chemical industry, industrial mixers are essential for the safe and efficient mixing of various chemical substances, including corrosive and explosive powders. Our mixers are designed to withstand harsh conditions and offer flexibility in speed.

Conical mixers provide a three-dimensional mixing motion, ensuring even mixing without dead zones. They are ideal for mixing powders and granular materials and are commonly used in the pharmaceutical and chemical industries.

In the pharmaceutical industry, mixers are crucial for accurately blending active ingredients with excipients. Jongia’s mixers provide the precision and hygiene necessary for the consistency and effectiveness of medications.

The main advantages are speed, homogeneity, durability, and versatility. Our mixers are designed for efficient mixing of various ingredients and can be customized to meet the specific requirements of each industry.

Characteristics of our mixing equipment and products are: High quality, Durability, Environmentally friendly, Low maintenance. Depending on the application we divided our top, side and bottom entry agitator types into 3 levels: light, medium and heavy duty.

Yes, Jongia provides tailored mixing solutions fully adapted to the customer’s specific processes. Our engineering team works closely with clients to deliver the best solution.

In addition to supplying high-quality products, Jongia offers comprehensive technical support, including maintenance, spare parts, and equipment installation, ensuring uninterrupted production processes.

Frequently Asked Questions

What is an industrial mixer and what is it used for?

An industrial mixer is a device designed to uniformly mix solids, powders, and liquids for a variety of industrial applications, particularly in the pharmaceutical and chemical sectors. They ensure consistent product quality and process efficiency.

How are industrial mixers applied in the chemical industry?

Industrial mixers are vital in the chemical industry for the safe and efficient blending of various chemical substances, including explosive and corrosive materials. Our mixers are engineered to perform optimally in harsh conditions with adjustable speed settings.

What are the benefits of conical mixers?

Conical mixers are distinguished by their three-dimensional mixing motion, which eliminates dead zones and ensures uniform mixing. These mixers are particularly effective for powders and granular materials, making them ideal for use in the pharmaceutical and chemical industries.

What role do industrial mixers play in the pharmaceutical sector?

In pharmaceuticals, mixers are essential for blending active ingredients with excipients accurately. Jongia’s mixers ensure the precision and hygiene necessary for medication consistency and effectiveness, ultimately enhancing product quality.

What are the key advantages of Jongia’s industrial mixers?

Jongia’s industrial mixers offer advantages such as high speed, homogeneity, durability, and versatility. Customization options allow them to meet specific industry requirements, making them an excellent choice for diverse applications.

Challenge us to improve your process

Contact us today to learn more about our extensive range and how we can assist you with customized mixing solutions to elevate your production process.

Tom Pruymboom

Sales Director

Area Worldwide

Bart Brouwer

Area Sales Manager

Area Worldwide

Popular Articles

Do I need a Bottom Bearing for my agitator?

Do I need a Bottom Bearing? The installation of a bottom bearing is not mandatory. While it offers certain advantages, there are also drawbacks to consider. It is important to note that the bottom bearing functions more as a displacement

Fermentation & Bioreactor Mixing Process

Bioreactors and Fermenters are culture systems to produce cells or organisms. They are used in various applications, including basic research and development, and the manufacturing of biopharmaceuticals, food and food additives, chemicals, and other products. A broad range of cell types and organisms can be cultivated in bioreactors and Fermenters, including cells (like mammalian cell lines, insect cells, and stem cells), microorganisms (like bacteria, yeasts, and fungi), as well as plant cells and algae. The words “Bioreactor” and “Fermenter” are basically the same thing.

Biodiesel blending with zero leakage!

Fuel blending is a critical component of biodiesel production. A properly blended fuel can increase energy efficiency, reduce emissions and improve performance. However, it can be difficult to achieve consistent fuel quality during blending due to differences in storage tanks,