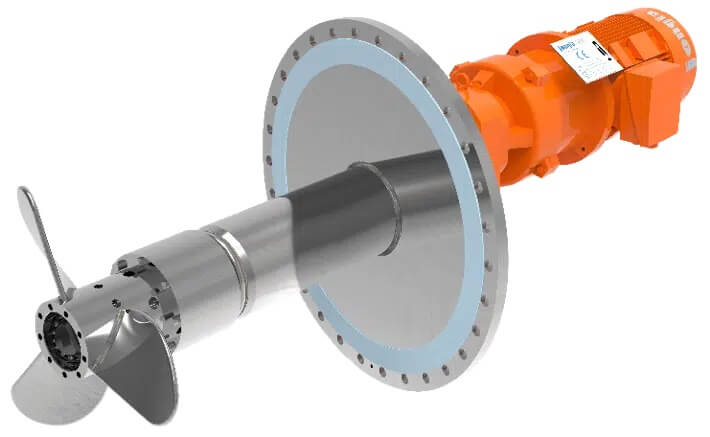

Magnetic Mixer

Magitator – Magnetic Mixer for Pharma, Food & Chemical industry

Requirements for the mixing equipment to be used depend on specific characteristics such as viscosity and density which vary considerably.

To keep the product homogeneous our Magitator, a magnet driven mixer, is the right choice. Certain additives and solids can be mixed into the fluid when injected into the zone of the mixing head.

Opting for the Magitator ensures that the tank can remain hermetically closed under highly sanitary conditions. The open design of the mixing head ensures an optimum flow for easy cleaning and efficient mixing. The cleanability of the magitator is compliant with the most stringent CIP and SIP requirements. Zero-emission is ensured and in addition the absence of a mechanical seal considerably cuts down on maintenance costs.

The Magitator can be mounted as a side or bottom entry mixer. Depending on the process and product requirements a motor will be selected from a power range of 0,5 – 11 kW.

All brands of Motor/gearbox drives can be supplied as well as explosion-proof motors up to ATEX Zone 1 and 2. In principle the Magitator is of standard design, however the mixer can be custom-made and adapted to your process.

The Magnetic Mixer is available as a Side Entry Mixer (JMW) and a Bottom Entry Mixer (JMB).

In this tutorial we show you how the Magitator is assembled and how it works under very hygienic conditions because the tank remains hermetically closed.

Magitator Posts

Biodiesel blending with zero leakage!

Fuel blending is a critical component of biodiesel production. A properly blended fuel can increase energy efficiency, reduce emissions and improve performance. However, it can be difficult to achieve consistent fuel quality during blending due to differences in storage tanks,

Tutorial: How does the Magitator work?

To keep dairy or starch products homogeneous, the Jongia Mixing Technology Magitator, a magnet-driven agitator, is the right choice. In addition, this agitator maintains vegetable oil or juices at the right temperature. In this tutorial we show you how the

The Jongia Magitator: The solution for zero emission and leakage free mixing!

Side-entry agitators and mixers in the product range of Jongia Mixing Technology are the best fit for applications such as keeping dairy or starch products homogenous or keeping vegetable oil or juice storage on the right temperature. For these applications

Contact our specialized team for all your questions

Tom Pruymboom

Sales Director

Area Worldwide

Bart Brouwer

Area Sales Manager

Area Worldwide

Technical Questions?

Sijko van der Veen

Application Engineer

Technical Specialist