Axial Flow Turbine Mixing Element

In order to provide a visual explanation of the operation of the Axial Flow Turbine, we have included a video tutorial. Check it out below!

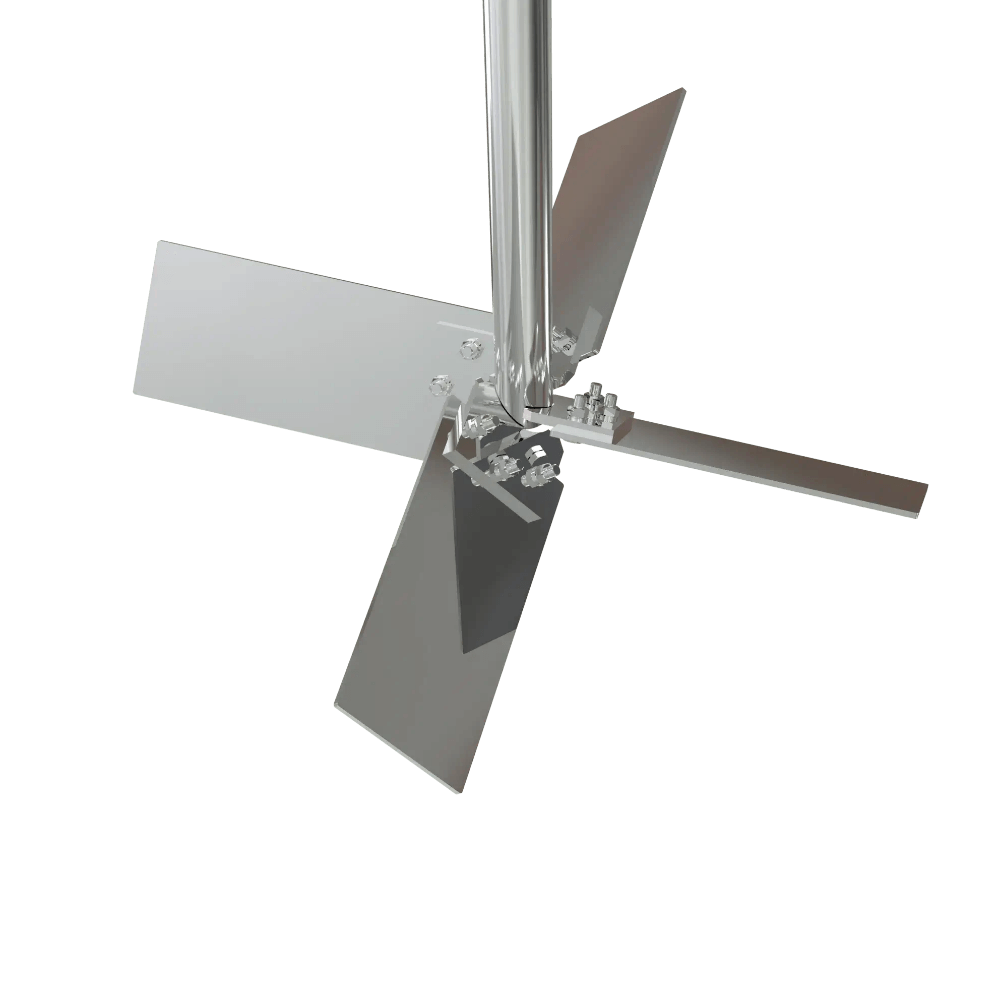

Axial Flow Turbine Bolted

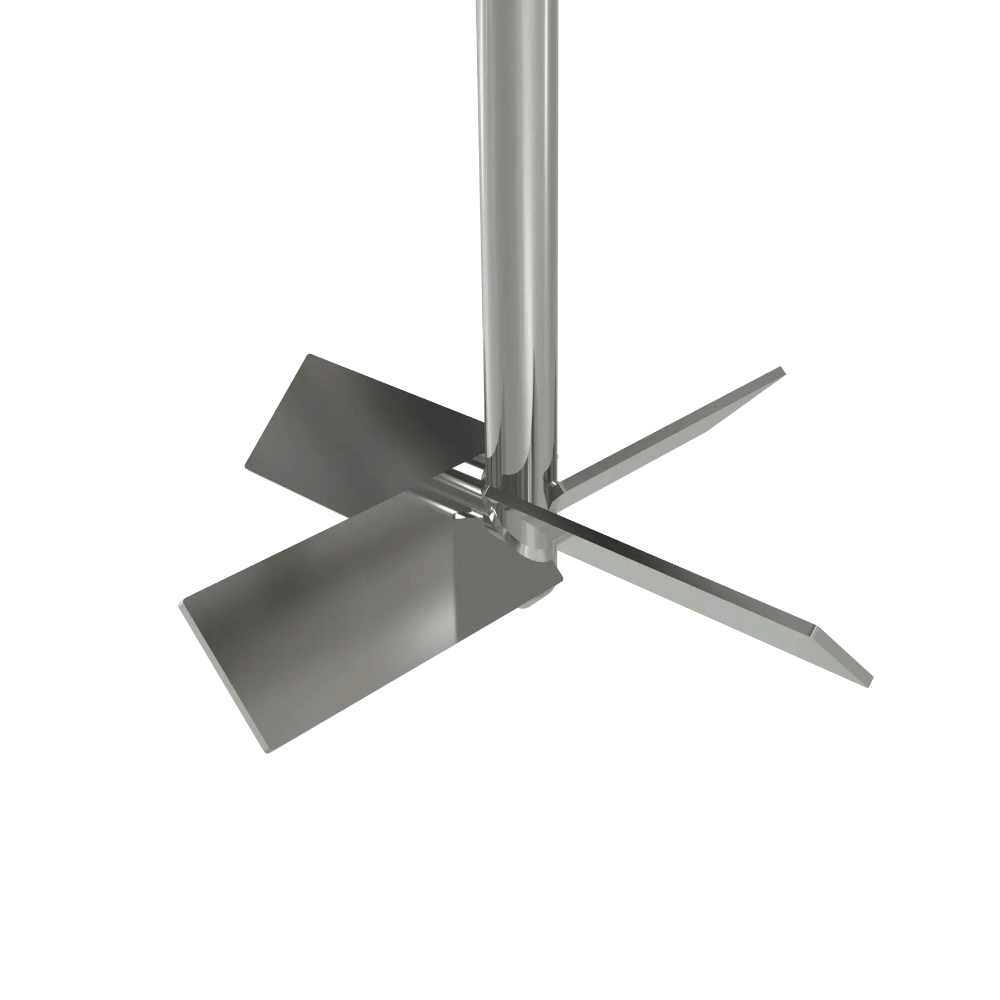

Axial Flow Turbine Welded

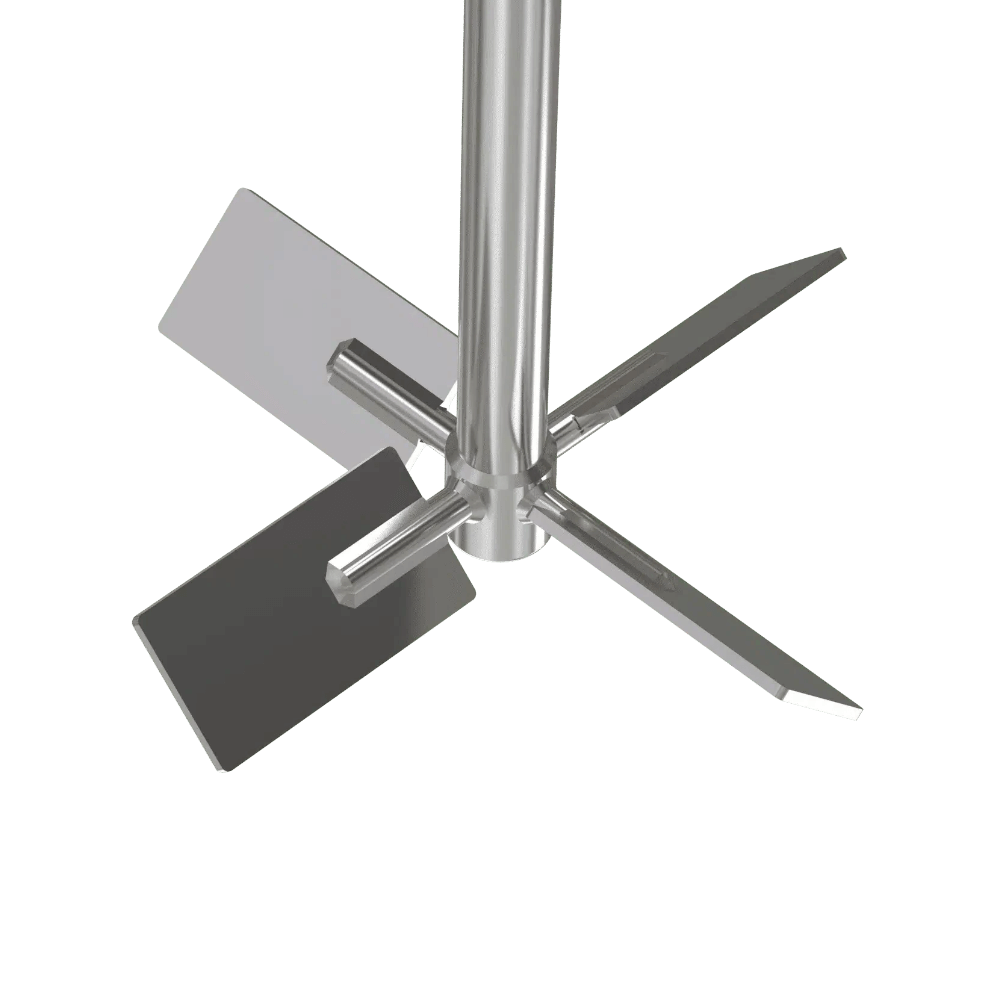

Axial Flow Turbine Pin

Tutorial Axial Flow Turbine

In this tutorial, Commercial Director Tom Pruymboom shows you the process of starch gelatinization using a labscale test unit. In it, raw starch is dissolved in 10 liters of water and the mixture is then heated using a heating coil. When it has become a gel, enzymes are added to convert the mixture to glucose. The mixing is done by a mixer shaft equipped with a 2-blade residual stirrer, a 4-blade Axial Flow turbine and a Hydroprop mixing element for a top-over-bottom stirring process with axial flow.

Related Articles

High-Speed Disperser Technology: The Engineering Behind Effective Mixing

A Technical Guide by Jongia Mixing Technology Core Function High-speed dispersers excel at three critical tasks: Fracturing powder agglomerates into fine particles Creating uniform powder distribution throughout liquid mediums Facilitating complete dissolution of soluble materials Operating Principles High-speed dispersers transform

VVTI Biogas Tilburg

VTTI Biogas Tilburg is developing a new bio-energy facility, focusing on processing organic waste. The plant is expected to produce approximately 23 million cubic metres of biogas annually. A portion of this will be converted into green gas for the

Homogenization and Cooling in Diary Cream Production

Utilizing Jongia’s Cup Mixer Homogenization is a standard procedure employed in dairy cream production to ensure the consistent distribution of fat globules in both milk and cream. This process, achieved through a high-pressure homogenization apparatus, breaks down and disperses fat