Jongia Mixing Technology has initiated numerous mixing processes all over the world using her agitators. In some of these mixing processes, crystallization was a key factor in acquiring the desired final product. The process of crystallization is well-known in the chemical industry, pharmaceutical industry, and food industry. In many cases, crystallization is a process that occurs as part of the process requirements for cooling a liquid, enabling crystal formation. Jongia Mixing Technology has supplied crystallization agitators for many projects. In this article, we will highlight the Batch crystallization process for the dairy industry.

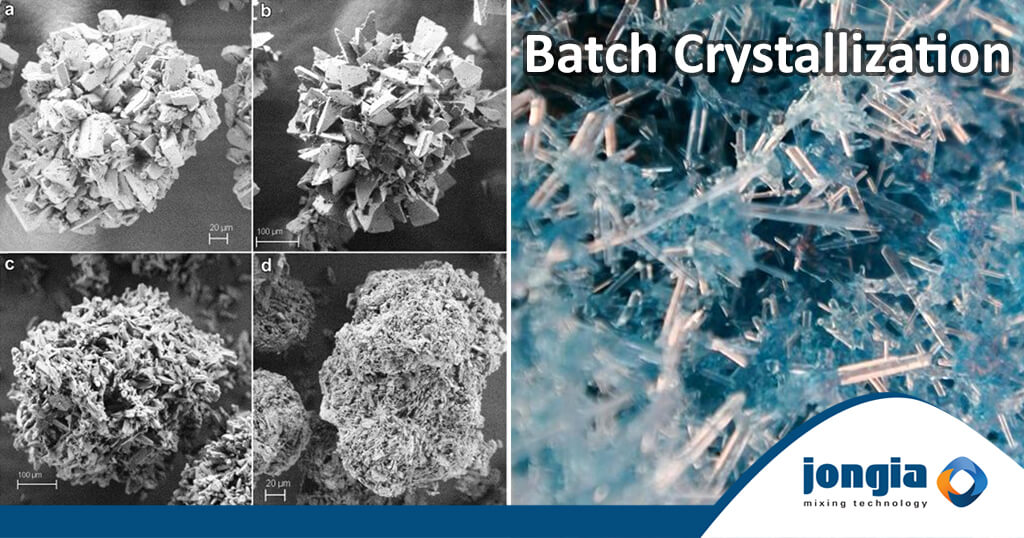

Batch crystallization

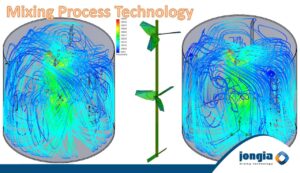

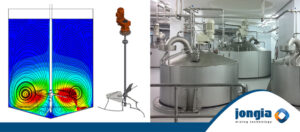

When designing Batch crystallization, a central agitator shaft is generally applied, in conjunction with Hydrofoil or Hydroprop agitator blades. This is due to the need for the agitator blades to run very smoothly through the fluid to guarantee the proper velocity in the mixing tank, as well as to keep the fluid in motion without causing any damage. The temperature inside the tank needs to be lowered in order to start the crystallization process. The Jongia Mixing Technology agitators provide a flow inside the tank, ensure the cooling provided by the tank walls is evenly distributed throughout the whole tankwall. The agitator is designed according to tank volume and fluid viscosity. This means that the agitator blades and shaft rotations are adjusted to the crystallization process. In some cases, the agitator commonly works on variable speeds . The most important function of the agitator is cooling the fluid within a certain time span as well as homogenizing it through smooth agitation. As such, the design parameters of the agitator, the agitator blades and the tank geometry are paramount in gaining the appropriate function of the crystallization process.

Experience with Batch crystallization results in perfect mixing process

Jongia Mixing Technology has years of experience in Batch crystallization. This began in the dairy industry, where Jongia Mixing Technology designed an agitator for crystallizing lactose. In this case, it was a lactose concentrate of approximately 62% that needed to be cooled from 95 degrees Celsius in the first phase down to around 75 degrees Celsius. The suspension needed to be kept at this temperature for a short period of time, after which the cooling phase of about 7 degrees Celsius per hour started, until the desired temperature of 60 degrees Celsius was reached.

The agitator was equipped with a frequency converter in order to increase rotation speed, resulting in an increase in cooling capacity. The agitator itself needed to be cooled down to 50 degrees Celsius at an even higher temperature drop rate per hour. When this temperature level, with the given speed, was reached, the agitator had to increase the cooling capacity again to a drop rate of 15 degrees Celsius per hour. The cooling capacity and cooling water temperature are of high importance in the crystallization process. Capacity and constant temperature in the tank cooling jackets must be maintained at all times to ensure optimal cooling by the agitator, resulting in perfect crystallization.

Agitator set-up

The shape of the Hydrofoil blades designed by Jongia Mixing Technology, in combination with a rest stirrer, create a smooth top over bottom velocity in the tank. Halfway down the agitator shaft, two extra Hydroprops can be applied to increase axial flow. In most cases, the Hydroprop agitators have a fairly large surface, and the blades are oriented as such that they pump from the top downwards. In some cases, however, the agitator can be equipped with a set of Hydrofoil blades oriented to pump upwards.

Want to know more about the crystallization process?

As with all mixing processes, the crystallization process requires a specific approach. Jongia Mixing Technology possesses all knowledge and experience to give broad advice regarding this process. If you have any questions, please do not hesitate to contact us.

Contact our specialized team for all your questions

Tom Pruymboom

Sales Director

Area Worldwide

Bart Brouwer

Area Sales Manager

Area Worldwide

Technical Questions?

Sijko van der Veen

Application Engineer

Technical Specialist

Mixing Process Technology

Mixing Process Technology The mixing process has different applications in many process industries. In the food industry, mixing in all variations using mixing technologies remains a routine and critical unit operation. Mixing solvent sweeteners into water-based beverages, mixing carbon dioxide

Tutorial: Batch Crystallization

Jongia Mixing Technology has initiated countless mixing processes all over the world with the help of her agitators. In a number of these mixing processes, crystallization is of great importance to obtain the desired final product. In this tutorial, Area

The crystallization process in the pharmaceutical industry

Jongia Mixing Technology has initiated numerous mixing processes all over the world using her agitators. In some of these mixing processes, crystallization was a key factor in acquiring the desired final product. The process of crystallization is well-known in the

Tutorial: How do we mix native starches?

Jongia Mixing Technology has initiated many mixing processes worldwide with its agitators. This includes mixing processes in which native starch is one of the products to be mixed. Native starch is widely used in the food and paper industries. We

Customized agitators make for a satisfied starch manufacturer

Native starch is used as base material in many applications. Native starches manage texture, control moisture content, and stabilize products, making them the ideal material for food applications. About native starches Native starches are insoluble in cold water and swell

Tutorial: How does the Hydroprop work?

To keep starch in suspension, for crystallisation processes and to keep a biogas process in motion, Jongia Mixing Technology has a perfect agitator in its range: The Hydroprop. In this tutorial we want to show you that the Hydroprop is