Petrochemical

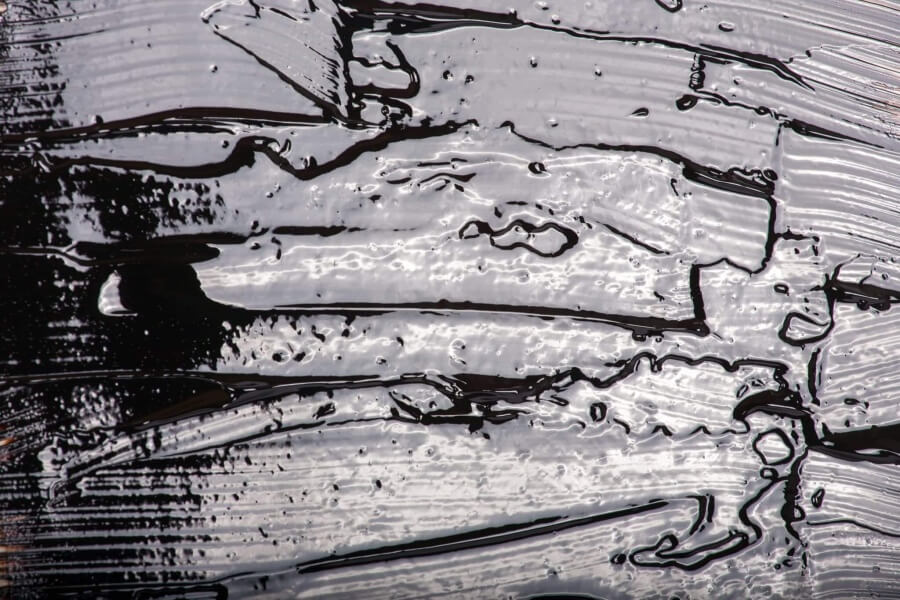

The petrochemical industry starts often with the storage of crude oil, waiting to be refined and processed. With the storage of the crude oil customers have to deal with BS&W (Basic Sediment & Water), heat transfer and homogenization issues. Jongia engineers have developed side entry mixers for these applications based on CFD (Computational Fluid Dynamics) analysis and know-how, resulting in the most effective and efficient induced flow in the tank.

Jongia engineers are able to calculate on blending time and tank cycles for additives on fuel oils, kerosenes and diesels. Given the current global energy transition these types of fuels are getting more and more important for the industry as well as for the end users.

Maximum performance at minimum power input

Further downstream where these products are being refined and processed to petrochemicals, Jongia has a lot of reference projects in monomers and polymers. From low viscous premix slurries to high viscous polymers in high pressure reactors, Jongia will design the most effective mixing element for best performance. Anchor type low speed mixing element will be challenged by a CRM geometry to gain the maximum output. In line dynamic mixing in Butyl-rubber process streams have been designed by our engineers for the most effective particle size (microns).

Jongia’s empiric know-how and theoretical knowledge results in the maximum performance and output of your process, based on the fact that we also make a cross reference on different technologies in another industry processes.

Applications

Crude oil

Bitumen

Fuel oil

Plastics

Other Chemical Industries

Petrochemical – Related Articles

Jongia and OptiMix from De Dietrich

Jongia Mixing Technology is now integrated into the De Dietrich Process Systems’ OptiMix Reactor & Agitator System. The OptiMix® Reactor & Agitator is an exclusive product range from De Dietrich, designed to perform in the most hazardous environments. Its enamel coating offers

Meet Menno: Our Experienced Calculator at Jongia Mixing Technology!

Introduction to Menno Zuidema Menno Zuidema is engineer, who takes care of cost calculations and work preparation at Jongia Mixing Technology. He comes from Groningen (city) and now lives in Balk, Friesland. Menno is married and has two children. He

Jongia Mixing Technology Welcomes Students from the University of Groningen for an Engaging Visit

Today, Jongia Mixing Technology had the pleasure of hosting two groups of students from the University of Groningen. This visit was organized in collaboration with Wafilin Systems & FIB industries, providing the students with the opportunity to explore both companies