It all started around Christmas 2013 when Jongia was asked by Titan Projects, specialist in supplying complex process equipment worldwide, to quote for agitators for their Austrian salt project. Together with Titan Projects it took over 9 months to fine-tune the specifications of the agitators to meet with the requirements of the end-user and to close the order.

We offered agitators based on our experiences at Frisia Zout in Harlingen, part of ESCO (European Salt Company) where we supplied and currently service 8 mixers for the identical application. These agitators have been in use for approximately 20 years now. This excellent reference, CFD modelling, flexibility, quick reactions and close technical/process discussions, convinced Titan Projects and the Austrian end customer of our skills and that gave us the advantage over our competitors.

The Project

Naturally we were proud and pleased to be awarded the order for this prestigious project by Titan Projects! The order consists of the supply of 4 agitators, 3 replacement shafts for existing agitators and also includes mounting & supervision by our experienced service engineers at the plant. Efficiency and mixing degree were key challenges in this project and our process mixing know how and engineering skills won us the order.

Mixing efficiency

The four agitators are specially designed to reduce the time (by >50%) needed for clarification of the liquid. The final result was a clarification time reduction by 65%. Three agitators are used for the distribution of CO2 into a liquid substance. Due to our design of the sparger in combination with special agitator elements, the reaction time was reduced by more than 50%.

Our client speaks

Koos Boersma, one of the owners and director of Titan Project says: „From the start of the discussions with Jongia we had a good feeling about the expertise of Jongia and good references Jongia has in this market and especially with the process at Frisia Zout. For the project the co-owner of our American subsidiary was the construction manager at that time and the process is similar to the process in the Austrian salt project. What gave us the final push to go ahead with Jongia was their flexibility in thinking with us during the pre-engineering process and the quick response. Furthermore Jongia was a step ahead of the competition and the pre-order work was very clear and convincing. I am very satisfied with the close partnership with Jongia and personally about the given process guarantee on the agitator process performance which exceeded our expectations”.

Installation & Commissioning

Part of Jongia’s scope of supply was the installation/commissioning of the agitators & shafts. Our specialized field engineers drove their well equipped service cars to the Austria.

The installation was performed satisfactorily in a short period of time and so the project commissioning was met within the envisioned timeframe. The end client is very pleased with our hands-on skills, our knowledge and expertise in agitators and last but certainly not least the far better than expected performance of the agitators. This resulted in a new project through Titan Projects for 4 more agitators!

Teamwork!

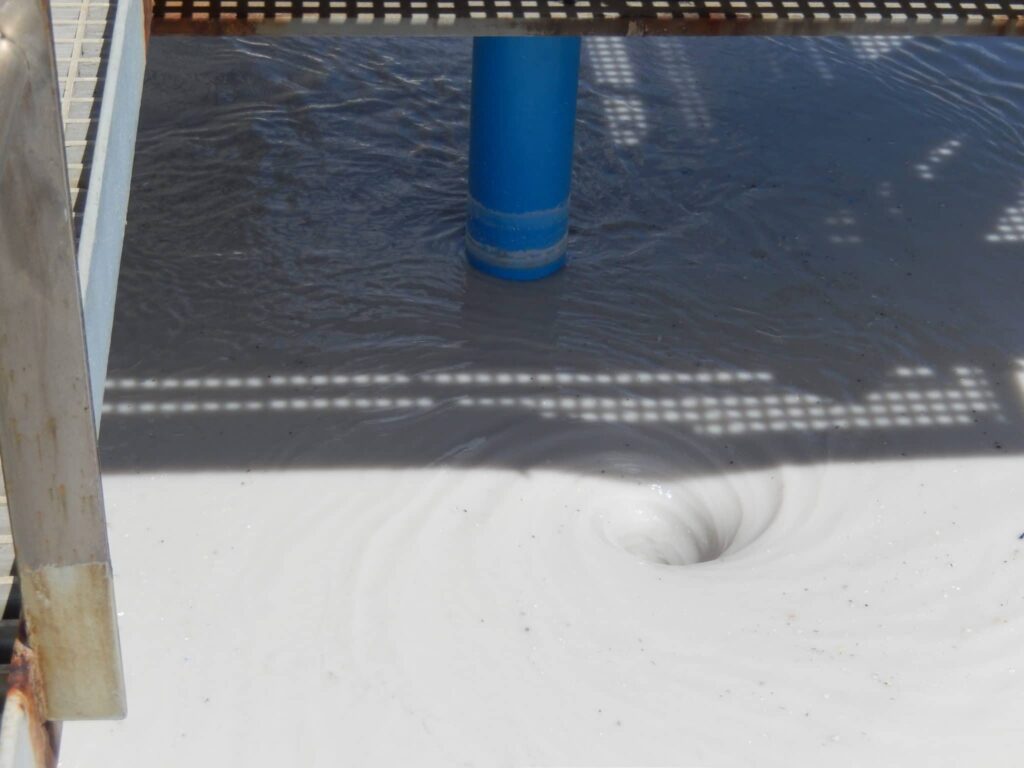

Here’s a picture of the proud team that made it all happen, it also gives a good impression of how large these agitators are..

Contact our specialized team for all your questions

Bart Brouwer

Area Sales Manager

Area Worldwide

Technical Questions?

Jan Siert Tjeerdsma

Project Manager

Technical Specialist

Related Articles

Steinfort Glass selects Jongia Mixing Technology

Meet Mr. Gerlof Reineker, general manager of Steinfort Glas in Franeker. Steinfort Glass specializes in processing flat glass for various applications. The company purchases large sheets of glass and processes them into products such as shower doors, office glazing, bus

Jongia agitators with Nord Maxxdrive gearboxes for Smits Group biogas plant

Jongia Mixing Technology recently delivered a series of agitators with Nord Maxxdrive gearboxes for the biogas plant of Brabant-based agricultural company Princepeel, part of the Smits Group. These ‘heavy duty’ Agitators optimally withstand the high torques required to move the

VVTI Biogas Tilburg

VTTI Biogas Tilburg is developing a new bio-energy facility, focusing on processing organic waste. The plant is expected to produce approximately 23 million cubic metres of biogas annually. A portion of this will be converted into green gas for the