Engineering Services

Jongia Mixing Technology is a company that provides engineering services in the field of mixing and agitation technology. Our engineering services include the design, engineering, manufacture and installation of mixing and agitation systems for various industries, such as the chemical, pharmaceutical, food and biotech industries.

Jongia’s engineering services cover a wide range of activities, from feasibility studies and process design to customized equipment manufacturing and on-site installation. We work closely with our customers to understand their specific needs and requirements and provide customized solutions that meet their technical and operational needs.

Some of the specific engineering services we offer are process optimization, equipment size and selection, mechanical and electrical design, project management, commissioning and training. We also provide after-sales support and maintenance services to ensure the reliable and efficient operation of their equipment.

Overall, Jongia’s engineering services are focused on providing high-quality mixing and agitation solutions that improve the performance, productivity and profitability of their customers’ operations.

Process Optimization

Process optimization is the process of improving an existing process to improve efficiency, productivity and quality and reduce costs. It includes analyzing the current process, identifying opportunities for improvement, developing solutions and implementing these improvements.

Among other things, we use our own Technology Center

Jongia’s Technology Center allows us to refine our customers’ process to ensure the best possible results. In close cooperation with our R&D team, our customers have been able to achieve significant process improvements.

The Technology Center at Jongia is a facility that focuses on developing and testing new mixing and agitation technologies and solutions. The center provides an environment where customers and partners can work with Jongia’s experts to develop and test innovative and customized mixing and agitation systems.

The Technology Center features advanced testing equipment and instruments, such as flow meters, density and temperature sensors, and a range of different mixing and agitation equipment. This makes it possible to analyze and evaluate the physical processes that take place during the mixing and agitation of liquids and gases.

Jongia testunits

Jongia Mixing Technology has developed various test units with a capacity of up to 250 liters, in which the most diverse mixing processes are tested. From food to wastewater and from chemical cleaning agents to biogas, the test units are used in many areas.

Our senior process technologist are happy to take on the challenge with you! Together we achieve the best process result. Once that is achieved, there is much more control over the process and the ideal situation is then applied on an industrial scale.

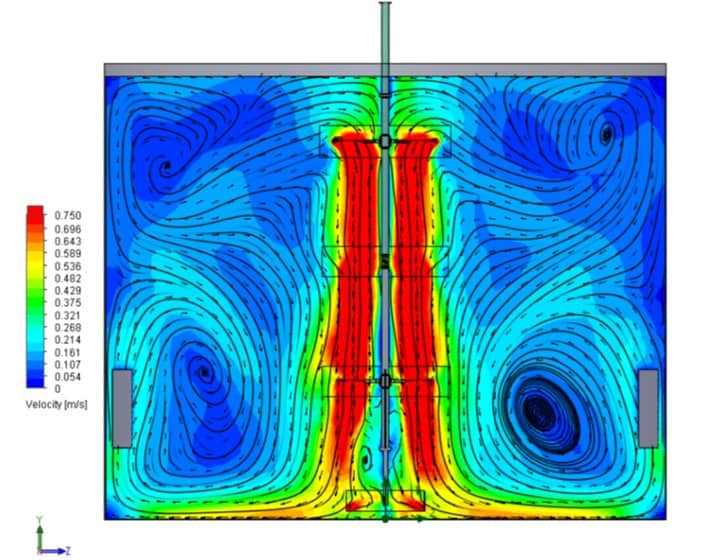

CFD-Analyse

Jongia Mixing Technology uses CFD analysis to optimize the flow dynamics and performance of their mixing and agitation systems.

Through CFD analysis, Jongia’s engineers can model and calculate the flow patterns, pressure distribution, temperature distribution and other parameters in the mixing process. This can help identify potential problems and inefficiencies in the process and find solutions to improve performance and efficiency.

Jongia Mixing Technology also uses advanced simulation software to design new mixing and agitation systems and to optimize existing systems. These simulations allow us to test and evaluate different designs and parameters before building physical prototypes. This can lead to a better understanding of the physical processes and a more efficient and effective design.

LiquidZ Sensor Technology

LiquidZ Sensor Technology focuses on the development and production of advanced sensor technologies for the detection and measurement of liquid levels and quality in various applications.

Jongia – Liquidz has developed a number of specific mixing sensors that turn an agitator into a sensor that can measure mixing parameters in the process. By applying data-science to this available data, the customer’s process can be optimized. The “Liquidz” project is all about collecting and analyzing process data to optimize the process and run your stirring process optimally.

Liquidz Sensor Technology offers a wide range of liquid level sensors that use different measurement methods, including capacitive, ultrasonic and pressure-based sensors. These sensors are suitable for various applications in industrial processes.

Frequently Asked Questions

What services does Jongia Mixing Technology provide?

Jongia Mixing Technology offers engineering services in mixing and agitation technology, including design, manufacturing, and installation of systems for industries like chemical and food. We focus on customized solutions and collaborate closely with clients to meet specific operational needs.

What types of industries does Jongia serve?

Jongia serves various industries including chemical, pharmaceutical, food, and biotech. Our expertise in mixing and agitation systems is tailored to meet the unique demands of these sectors, ensuring improved operational efficiency and product quality.

How does Jongia optimize processes?

Jongia specializes in process optimization, which involves analyzing existing workflows to enhance efficiency and quality while reducing costs. We develop and implement tailored solutions, often utilizing our Technology Center for testing and refining processes to achieve optimal results.

What is the Technology Center?

The Technology Center at Jongia is designed for developing and testing innovative mixing solutions. It features advanced testing equipment and enables collaboration with clients to analyze processes, ensuring efficient and effective designs through hands-on experimentation and R&D.

What is LiquidZ Sensor Technology?

LiquidZ Sensor Technology focuses on advanced sensors for measuring liquid levels and quality. It transforms agitators into sensors that provide data to optimize mixing processes, utilizing various measurement methods like capacitive and ultrasonic sensors suitable for industrial applications.

Contact our specialized team for all your questions

Tom Pruymboom

Sales Director

Area Worldwide

Bart Brouwer

Area Sales Manager

Area Worldwide

Popular Articles

Do I need a Bottom Bearing for my agitator?

Do I need a Bottom Bearing? The installation of a bottom bearing is not mandatory. While it offers certain advantages, there are also drawbacks to consider. It is important to note that the bottom bearing functions more as a displacement

Jongia Mixing Technology’s Evolution: Embracing the New De Dietrich Identity

A New Chapter for Mixing Technology Expertise As many of our valued partners and clients have noticed, Jongia Mixing Technology is entering an exciting new chapter as part of the De Dietrich family. This March, De Dietrich unveiled a comprehensive

High-Speed Disperser Technology: The Engineering Behind Effective Mixing

A Technical Guide by Jongia Mixing Technology Core Function High-speed dispersers excel at three critical tasks: Fracturing powder agglomerates into fine particles Creating uniform powder distribution throughout liquid mediums Facilitating complete dissolution of soluble materials Operating Principles High-speed dispersers transform