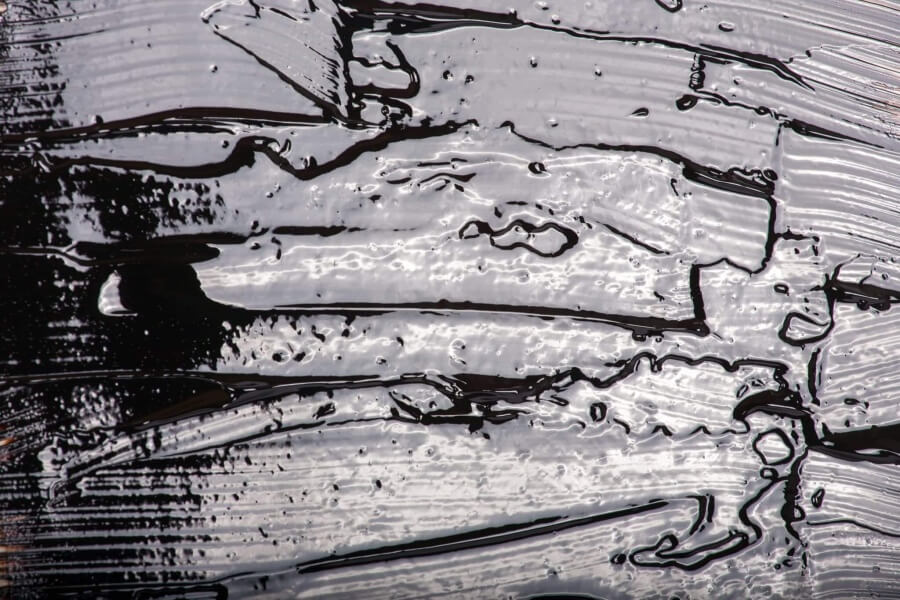

Bitumen

Bitumen is a petroleum-based product obtained from crude oil. By filtering and removing the light elements from the crude oil, bitumen is obtained through refining. The light elements extracted from the oil are usually naphtha, gasoline and diesel fuel. Then the bitumen remaining after distillation forms a hydrocarbon.

Maximum performance at minimum power input

The production of bitumen

Despite the fact that bitumen is a solid at standard ambient temperatures. In physics, bitumen is considered a liquid substance.

Bitumen is known for its waterproofing and adhesive properties and is often used in construction, especially for highways and there is a large supply of bitumen roofing material today.

Bitumen is produced by distillation. In this process, lighter components of crude oil, such as gasoline and diesel, are removed and the heavier bitumen remains. Deposits can also form naturally at the bottom of ancient lakes, where prehistoric organisms have decayed and been exposed to heat and pressure.

Bitumen market trends

The global bitumen market was USD 49.45 billion in 2020. The market is expected to grow from USD 51.69 billion in 2021 to USD 67.14 billion by 2028.

The global market is expected to grow significantly due to the rapid growth in demand in the construction industry. Especially in the areas of roofing and building new roads, bitumen is increasingly being used.

About ten percent of all bitumen made is used for roofing. Bitumen roofing membrane is increasingly used in the Netherlands given its easy installation and high quality. Eighty-five percent of all bitumen produced is used to make asphalt, this in turn eventually results in the making of new (highway) roads.

Finally, bitumen is used for sealing purposes. These can include products such as: primer, paint, coating and sealing products.

Frequently Asked Questions

What is bitumen?

Bitumen is a petroleum-based product derived from crude oil. It is obtained through the refining process, which involves filtering and removing lighter elements like naphtha and gasoline. The remaining material forms a hydrocarbon that is often used in construction and roofing.

How is bitumen produced?

Bitumen is produced through distillation. This process removes lighter components from crude oil, leaving behind the heavier bitumen. Additionally, natural deposits can form in ancient lakes where organic material has decayed and experienced heat and pressure over time.

What are the uses of bitumen?

Bitumen is primarily used for waterproofing and in construction. It is essential for building highways, roofing materials, and sealing products like primers and coatings. Approximately 85% of produced bitumen is utilized to make asphalt for new roads.

What are the current market trends for bitumen?

The global bitumen market was valued at USD 49.45 billion in 2020 and is expected to grow to USD 67.14 billion by 2028. This growth is driven by increased demand in construction, particularly for roofing and road building applications.

What are the steps in the bitumen refining process?

The refining of bitumen includes several steps: atmospheric distillation, vacuum distillation, oxidation, blending, and storage. Each step contributes to the separation and enhancement of bitumen’s properties for various applications in construction and roofing.

Petrochemical Industry Contacts

Tom Pruymboom

Sales Director

Area Worldwide

Jan Siert Tjeerdsma

Project manager

Technical Specialist

Petrochemical – Related Articles

The Double Acting Axial Flow Turbine type AST-MTE mixing element

Operation of an AST-MTE Element Operation of an AST-MTE Element This element can be used in both CW (clockwise) and CCW (counterclockwise) directions. In one case, the inner AST element is downward-pumping with the outer tips pumping upward, and in

Jongia Mixing Technology Agitators in Process Installations

This reactor setup from Veenbrink RVS, equipped with Jongia agitators, forms the foundation for polymer production. The system is applied in an ATEX classified zone: the equipment zone 1 IIB T2, whilst the space itself is designated as zone 2

A New MD for Jongia Mixing Technology!

Leeuwarden, 23 April 2025 We are delighted to announce that we have a new Managing Director at Jongia Mixing Technology! Our new MD is Mr. Jean Philippe Pfeiffer. Jean Philippe has worked for De Dietrich for 29 years as Group

Bitumen refining process:

These are the various steps in the refining process:

- Atmospheric Distillation

- Vacuum distillation

- Oxidation

- Blending

- Storage

Atmospheric Distillation

In the first step of this process the crude oil will be heated in furnace up to 350°C and subsequently guided to a distillation column were the lighter fraction (propene, butane) evaporates. The middle fractions such as naphtha, kerosene, gasoil are removed for further treatment in other refinery units. The heavy fraction, non-boiling component, remains at the bottom.

Vacuum Distillation

In the second process step the heavy fraction is, heated up to 425°C. To remove the last traces of the lighter fractions(gasoil), the residue is introduced again into a distillation column, here the vacuum pressure, lowers the boiling temperatures and thermal cracking of the molecules can be avoided.

Oxidation

The bitumen will be further processed in an oxidator reactor, by blowing air through it at elevated temperatures (280°C).

The process of oxidation increases the stiffness and softening point of the bitumen.

Blending

Often all kind of qualities bitumen are being blended to the technical specification required by the end user. These products are mainly used for road construction, roofing, pavements, reservoirs coatings. Bitumen is kept in large storage stanks (Carbon Steel) with capacities ranging from 100.000-1.000.000 liters.

The assumed viscosity of these blends is in the range of 200-3000 cP, depending on the temperature. The purpose of the mixer is to mix several highly viscous liquids, sometimes having almost the character of a solid. Given the tank geometry either a top entry mixer type N is required, whilst the Jongia’s side entry mixer type RWM will be selected for the large volumes.

The mixer type RWM is designed with two heavy duty bearing sections to absorb the power and vibration created during the mixing process. The modified marine type propeller, up to diameters of 850 mm, is creating a maximum forward flow resulting in turnover (cycle) times of 6-12 hours.