Polymers

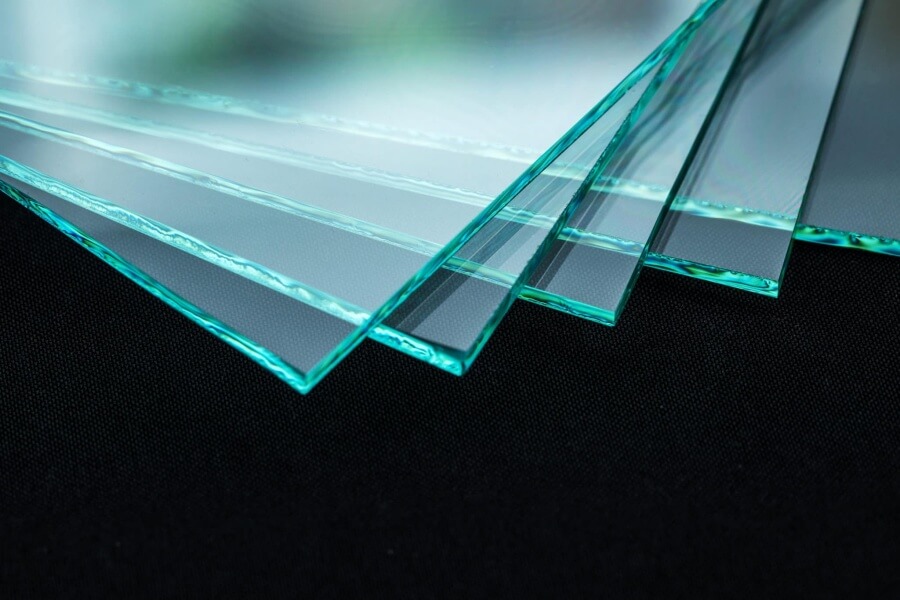

Polymer contain natural or synthetic substances made up of very large molecules. Such a large molecule are also called macromolecules. Polymers make up many of the materials in living organisms, including, for example, proteins, cellulose and nucleic acids. In addition, they form the basis of minerals such as diamond, quartz and feldspar and man-made materials such as concrete, glass, paper, plastics and rubbers.

Proper mixer selection is vital to process optimisation, for that you can rely on our experienced staff of engineers and process technologists.

What is polymer?

The word polymer stands for an indefinite number of monomeric units. When the number of monomers is very large, the compound is called a high polymer. Polymers are not limited to monomers of the same chemical composition or molecular weight and structure. Some natural polymers consist of one type of monomer. However, most natural and synthetic polymers consist of two or more different types of monomers.

Chemical Applications

Polymer market trends

The global polymer market was valued at $533.6 billion in 2019 and is expected to grow to a total value of $838.5 billion by 2030.

Increasing demand for polymers from industries such as automotive, electronics, construction, water treatment, waste management and energy is ensuring continued growth of the global polymer market.

The electrical and electronics industries mainly use polymers such as polyphenylene sulfide, nylon 46, polythiazide and polycyclohexylene terephthalate. These polymers are often preferred because they can withstand high temperatures.

Moreover, recycling plastics and obtaining sustainable polymers is another important factor driving the growth of the polymers market. This is because because recycling ensures that the amount of plastics entering the waste stream is reduced. Plastic recycling involves recovering plastic waste by reprocessing it into useful products.

The high volatility of raw material prices and strict regulations of regulatory bodies of various countries are major factors that are expected to hinder the growth market of the can.

Frequently Asked Questions

What are polymers?

Polymers are substances made of very large molecules, also known as macromolecules, formed from numerous monomeric units. They can consist of the same or different types of monomers and are found in both natural and synthetic forms. Examples include proteins and plastics.

What industries use polymers?

Industries such as automotive, electronics, construction, water treatment, waste management, and energy heavily utilize polymers. They are favored for their durability and versatility, making them essential materials for various applications across these sectors.

How is the polymer market projected to grow?

The global polymer market was valued at $533.6 billion in 2019 and is projected to reach $838.5 billion by 2030, driven by increased demand across multiple industries and a focus on recycling for sustainability.

What are the benefits of recycling polymers?

Recycling plastics reduces the volume of waste entering landfills while conserving resources. It promotes sustainability by transforming plastic waste into useful products and encourages the development of eco-friendly polymers.

What challenges does the polymer market face?

The polymer market faces challenges such as the high volatility of raw material prices and stringent regulations imposed by various countries. These factors could hinder market growth and impact profitability in the industry.

Chemical Industry Contacts

Tom Pruymboom

Sales Director

Area Worldwide

Bart Brouwer

Area Sales Manager

Area Worldwide

Jan Siert Tjeerdsma

Project manager

Technical Specialist

Chemical – Related Articles

Difference between precipitation and crystallization

Precipitation and crystallization are both processes involved in the formation of solid substances from a solution, but they occur under different conditions and result in different outcomes. 1. Precipitation: Precipitation occurs when a solid substance forms from a solution as

Tutorial: How does the Counterflow work?

The Counterflow is a very suitable mixing element for mixing processes of medium viscous liquid products such as paints, polymers and biodegradable plastics where starch is the basic component. In this tutorial we show you how the Counterflow moves the

The Counterflow: from request to solution

Mainly in the chemical industry, the Counterflow mixing element is applied in mixing processes of products such as paint, polymers, biodegradable plastics where starch is the basic component and medium viscous liquids. However, what kind of questions do the customers