Energy

Many years of experience in chemical and Bio-based applications enabled Jongia to propel in the new and fast growing business area of the Energy market. Jongia’s stirring and mixing equipment comply with extreme criteria concerning emission values, shaft alignment tolerances and rotational accuracy.

The newest energy markets require Mixing Technology at the lowest power consumption

Our innovative agitator portfolio is very suitable for the Energy industry. A low power consumption in combination with a high efficiency and reliability is what you need for your green energy label

Applications

Frequently Asked Questions

What experience does Jongia have in the energy market?

Jongia has many years of experience in chemical and bio-based applications, enabling them to excel in the fast-growing energy market. Our specialized stirring and mixing equipment meets strict criteria for emission values and operational precision.

What makes Jongia's mixing technology suitable for the energy sector?

Jongia’s mixing technology is designed for low power consumption while maintaining high efficiency and reliability, which is essential for achieving green energy labels in today’s market.

How do Jongia's products comply with industry standards?

Jongia’s stirring and mixing equipment is engineered to meet extreme criteria regarding emission values, shaft alignment tolerances, and rotational accuracy, ensuring compliance with industry standards.

What is the importance of energy efficiency in mixing technology?

Energy efficiency in mixing technology is crucial, especially in the evolving energy markets, as it helps reduce operational costs and supports sustainability initiatives. Efficient equipment contributes to lowering the carbon footprint.

How can I contact Jongia for inquiries related to energy products?

For inquiries regarding Jongia’s energy products, you can visit our contact page or reach out through designated channels provided in the “Energy – Contacts” section.

Energy – Contacts

Tom Pruymboom

Sales Director

Area Worldwide

Jan Siert Tjeerdsma

Project manager

Technical Specialist

Energy – Related Articles

Is Sodium-Ion the next generation sustainable Battery?

The sodium-ion battery (NIB or SIB) is a type of rechargeable battery that uses sodium ions (Na+) as its charge carriers. Its working principle and cell construction are almost identical with those of lithium-ion battery (LIB) types, but replace lithium with sodium.

What is the recycling process for lithium

Current commercial lithium ion batteries mainly contain transition metal oxides or phosphates, aluminum, copper, graphite, organic electrolytes containing harmful lithium salts, and other chemicals. Therefore, the recycling and reuse of spent lithium ion batteries has been paid more and more

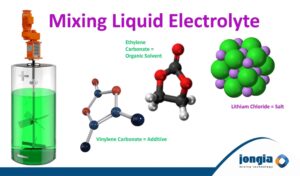

Mixing Electrolyte for Ion-Lithium Batteries

Electrolyte as basis for Ion-Lithium Batteries plays a key role in transporting the positive lithium ions between the cathode and anode, and consequently the charging and discharging performance of the battery. Hence, it needs to be checked for potential impurities.