Biogas

There are generally 3 types of digester plant types: Farm based, Industrial based and Municipality WWTP based. Mechanical mixing generates the best process results with the lowest power consumption. Far better then using pumps or compressors!

Depending on technology provider a digester plant can consist of following mixed process steps:

- reception storage tank

- mix tank

- primary digester

- secondary digester

- digestate storage tank

The newest energy markets require Mixing Technology at the lowest power consumption

Reception storage tank

Pumpable feedstock is received in tanks of 50 – 200 m3. Mostly products like separated and macerated organic food waste. The assumed viscosity of the mixture runs from 50-1000 cP. The purpose of the mixer is to keep it homogeneous or to mix several products . For this Jongia’s type L with hydrofoil elements is an excellent choice. With its high efficiency and axial generated flow the process result will be reached with low power need and steady operation. The mixer type L is designed with a bottom steady bearing or a heavy duty bearing arrangement to absorb the powers created during the mixing process.

Mix tank

Several different feedstock need to be mixed into a homogeneous feedstock to the digester. This mix is important to be homogeneous for a steady and controlled feed to the digester. Examples are food waste, macerated agricultural waste, manure and others. Let’s take cream as an example. The heavy duty top entry mixer type LB is fit for this step of the process.

Applications

Primary and secondary digester

In the digester there must be a homogeneous content off organics, pH, temperature and bacteria with no stagnant zones. Drymatter content in the digester of up to 15% is no problem. For industrial and municipality type of biogas plants with high tanks from 1.000 to 10.000 m3 the special slow running top entry mixer type LBW with large hydrofoil propellers is the best solution. This design prevents a floating layer and generates an excellent top over bottom bulk flow through the hole tank. Due to this Jongia mixers enhances excellent biogas production efficiency and extraction.

To prevent clogging of the mixer and trouble free operation, temporary running anti clockwise will prevent this. Especially when feeding long fibrous material like grass, straw or plastic from organic food waste.

For farm based biogas plants with low concrete tanks from 1.000 to 5.000 m3 Jongia provides type JRWM side entry agitators which have large hydrofoil propellers for big thrust and low power. Combined with vertical paddle mixers to prevent floating layer this solution generates optimal process results.

Frequently Asked Questions

What are the main types of digester plants?

There are three main types of digester plants: farm-based, industrial-based, and municipality wastewater treatment plant (WWTP) based. Each type has distinct needs and operational requirements tailored to its specific environment.

How does mechanical mixing contribute to the process?

Mechanical mixing is essential as it generates the best process outcomes with the lowest power consumption. It outperforms traditional methods like pumps or compressors, making it an efficient choice for biogas production.

What does a typical digester plant consist of?

A typical digester plant usually includes a reception storage tank, mix tank, primary digester, secondary digester, and digestate storage tank. The specific setup may vary depending on the technology provider.

Why is it important to maintain a homogeneous mixture in the digester?

A homogeneous mixture is crucial in the digester to ensure a consistent composition of organics, pH, temperature, and bacteria. This prevents stagnant zones and enhances biogas production efficiency, leading to improved extraction.

What type of mixer is recommended for digestate storage tanks?

For digestate storage tanks, the type JRWM side entry agitators, designed with large hydrofoil propellers, are recommended. They provide significant thrust and low power use, ensuring a well-mixed and homogeneous fertilizing end product.

Energy – Contacts

Tom Pruymboom

Sales Director

Area Worldwide

Jan Siert Tjeerdsma

Project manager

Technical Specialist

Energy – Related Articles

Is Sodium-Ion the next generation sustainable Battery?

The sodium-ion battery (NIB or SIB) is a type of rechargeable battery that uses sodium ions (Na+) as its charge carriers. Its working principle and cell construction are almost identical with those of lithium-ion battery (LIB) types, but replace lithium with sodium.

What is the recycling process for lithium

Current commercial lithium ion batteries mainly contain transition metal oxides or phosphates, aluminum, copper, graphite, organic electrolytes containing harmful lithium salts, and other chemicals. Therefore, the recycling and reuse of spent lithium ion batteries has been paid more and more

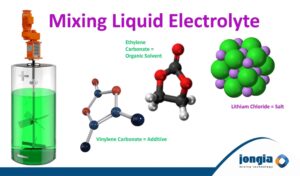

Mixing Electrolyte for Ion-Lithium Batteries

Electrolyte as basis for Ion-Lithium Batteries plays a key role in transporting the positive lithium ions between the cathode and anode, and consequently the charging and discharging performance of the battery. Hence, it needs to be checked for potential impurities.

Digestate storage tank

Our type JRWM side entry agitators which have large hydrofoil propellers for big thrust and low power are best suitable and are providing a good homogeneous fertilizing end product.

Some references:

HoSt, Omrin, Waterleau, Shanks, Orgaworld, Hydrothane, Adverio, Aben Recycling, van de Groep, Croda, GMB, Waterschap Roer en Overmaas.