Lithium-based battery technologies for electric vehicles use lithium-ions as the charge carrier. Depending on the application’s technical requirements, lithium is used with various chemistries such as graphite for the anode as well as nickel, manganese or cobalt oxides for the cathode. All these materials have good lithium insertion or intercalation properties, allowing to store large amounts of energy.

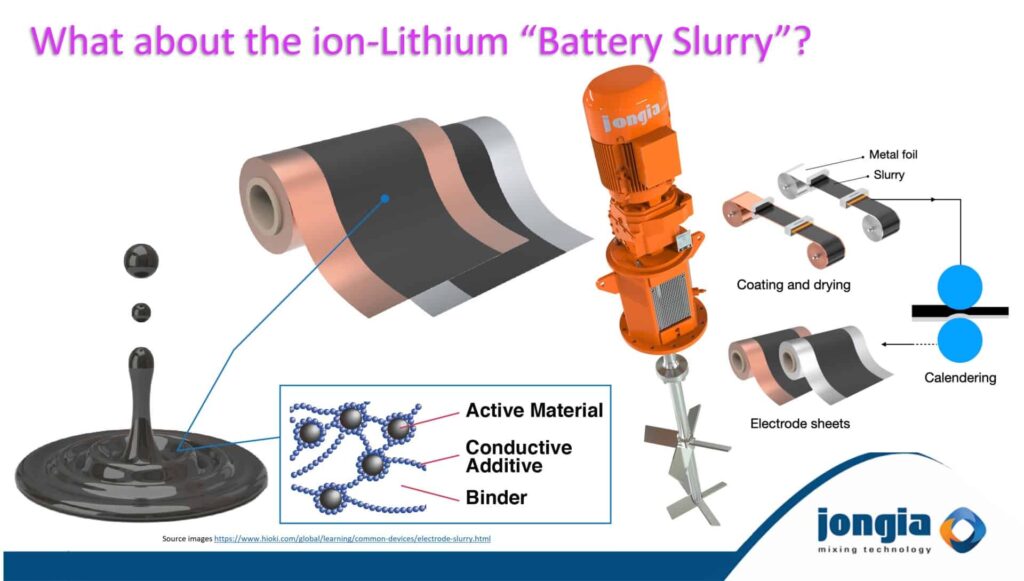

Each Lithium-Ion rechargeable Battery production and manufacturing process starts with the production of the suspension which becomes the so called “electrode slurry”

This suspension is a mixture of Active material, Conductive additives, a Solvent and a Polymer Binder. These materials all need to be mixed in a mixing vessel with a well selected agitator.

To explain the urgence of the appropriate Agitator selection, first we need to explain the importance of the electrode slurry itself.

What is electrode slurry ?

Basically, the electrode slurry consists of electrode materials dispersed in an organic solvent.

The electrode slurry once prepared for the following step will be coated to copper and aluminum foil, dried, and calendared.

This foil together with the applied slurry will act as cathode and anode.

Electrode slurry materials and their role

Active material : Reacting lithium ions

NMP Solvent : To dissolve polyvinylidene fluoride (PVDF),which is the most frequently

utilized binder in the cathode slurry formulation

Conductive additives : Serves to facilitate electron conductivity

Polymer Binder : Serves to bind active material, and conductive additives.

For high capacity Ion-Litium batteries, it is necessary to reduce the proportion of conductive additives and increase the ratio of active material. However, it is also important to have sufficient electron conductivity to reduce the internal resistance of the battery, and a moderate amount of conductive additives are required. This makes it important to optimize the active material and conductive additives deviation.

Effect of material dispersion of electrode slurry on lithium-ion batteries

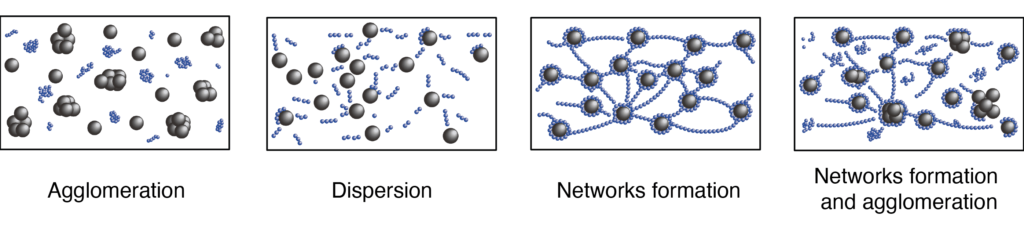

Dispersibility of active materials and conductive additives in electrode slurry is of very high importance. Let’s take a closer look at each material.

Active material

Ensuring contact of the electrolyte with the surface of each active material particle increases the ionic reaction. This will help to increase the battery capacity.

Conductive additive

If the electrode slurry is poorly mixed, the conductive additive will not disperse well enough.

Conversely, if the mixing is too strong, the flow of electricity formed will be destroyed and good electron conduction cannot be obtained.

Assembling the Lithium-Ion rechargeable battery without dispersing the active material and the conductive additives will concentrate the charge, which is undesirable because it causes non-uniform battery reactions.

The images show how the agglomeration will be formed when the appropriate mixer type is selected

The importance to choose the correct mixer type is as always depending on the following criteria:

- Volume size of the slurry components

- Capabilities of the slurry components

- Vessel geometry

- Orientation of the dosing nozzles for the slurry components

- Correct temperature and pressure control

- Selection of the appropriate mixing element set-up

- Correct speed to obtain sufficient turbulence and flow in the mixing vessel

- Mechanical reliability throughout the whole mixing process

To monitor the mixing process, Jongia recommends to apply sensor technology which enables easy read-out parametrics for the control room in the battery plant.

The mixer unit will need to run throughout the whole mixing process, which can either be a batch controlled procedure or a continuous mixing process.

The selection of the correct Mixing Element

Jongia Mixing Technology has a wide range of expertise for many suspensions, for dissolving and for continuous agitating, such as Propellers, Hydrofoils, Counterflow and sawblade mixing elements. Since the combination of the above listed criteria is of such importance, no typical one-type-mixing element is applied only. Instead, it is much more a combination of various mixing elements in combination with a variety of rotations and speed.

Therefor it is necessary to keep Jongia aligned during the pre-engineering and detailed engineering stadium to make sure the correct steps are taken for the appropriate agitator selection.

Furthermore, the mechanical reliability needs to be outstanding. That is another reason why Ion-Battery producers choose Jongia for their Lithium-Ion Battery Slurry agitator systems!

If you are interested, please contact us at: info@jongia.com or visit our Batteries page for more Ion-Lithium Battery related articles.

Contact our specialized team for all your questions

Bart Brouwer

Area Sales Manager

Area Worldwide

Sijko van der Veen

Application Engineer

Technical Specialist

Technical Questions?

Jan Siert Tjeerdsma

Project Manager

Technical Specialist

Related Articles

Is Sodium-Ion the next generation sustainable Battery?

The sodium-ion battery (NIB or SIB) is a type of rechargeable battery that uses sodium ions (Na+) as its charge carriers. Its working principle and cell construction are almost identical with those of lithium-ion battery (LIB) types, but replace lithium with sodium.

What is the recycling process for lithium

Current commercial lithium ion batteries mainly contain transition metal oxides or phosphates, aluminum, copper, graphite, organic electrolytes containing harmful lithium salts, and other chemicals. Therefore, the recycling and reuse of spent lithium ion batteries has been paid more and more

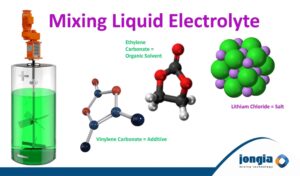

Mixing Electrolyte for Ion-Lithium Batteries

Electrolyte as basis for Ion-Lithium Batteries plays a key role in transporting the positive lithium ions between the cathode and anode, and consequently the charging and discharging performance of the battery. Hence, it needs to be checked for potential impurities.