Pharma & Personal Care

The accurate control of processes and attention to hygienic aspects are essential to mixing equipment that is used in the pharmaceutical industry.

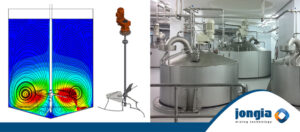

Jongia has an extensive range of dynamic mixers which can be used in applications instead of sterile magnetic mixers. We have a wide variety of mixing elements available that offer a solution for every application in the pharmaceutical industry.

We understand mixing is not just about simply combining raw ingredients

A few characteristics of Jongia’s mixing equipment with regard to pharmaceutical applications:

- Accurate process control.

- Efficient homogeneous mixing, preserving product integrity.

- The mixing systems can be sterilised and have been designed for CIP (Cleaning in Place).

Applications

Frequently Asked Questions

What are the main features of Jongia's mixing equipment for the pharmaceutical industry?

Jongia’s mixing equipment offers accurate process control and efficient homogeneous mixing while preserving product integrity. The systems are designed for CIP (Cleaning in Place) and can be sterilized, making them suitable for pharmaceutical applications.

How does Jongia ensure hygiene in its mixing processes?

Jongia emphasizes hygienic design in its mixing equipment. The systems can be sterilized and include CIP capabilities, ensuring that hygiene is maintained throughout the mixing process, which is crucial in the pharmaceutical industry.

Can Jongia's mixers be used in place of magnetic mixers?

Yes, Jongia provides a range of dynamic mixers that can serve as alternatives to sterile magnetic mixers. This variety allows for flexibility depending on the specific needs of pharmaceutical applications and processes.

What types of mixing elements does Jongia offer?

Jongia has a wide variety of mixing elements designed for various applications in the pharmaceutical industry. This diverse selection ensures that every specific mixing requirement can be effectively met with the appropriate equipment.

Why is accurate control important in pharmaceutical mixing?

Accurate control is essential in pharmaceutical mixing to ensure product quality and safety. It allows for precise ingredient combinations and consistency, which are critical factors in producing effective and reliable pharmaceutical products.

Pharma & Personal Care – Contacts

Contact our specialized team for all your questions

Tom Pruymboom

Sales Director

Area Worldwide

Bart Brouwer

International Sales Manager

Area Worldwide

Sijko van der Veen

Application Engineer

Technical Specialist

Pharma & Personal Care – Related Articles

Fermentation & Bioreactor Mixing Process

Bioreactors and Fermenters are culture systems to produce cells or organisms. They are used in various applications, including basic research and development, and the manufacturing of biopharmaceuticals, food and food additives, chemicals, and other products. A broad range of cell types and organisms can be cultivated in bioreactors and Fermenters, including cells (like mammalian cell lines, insect cells, and stem cells), microorganisms (like bacteria, yeasts, and fungi), as well as plant cells and algae. The words “Bioreactor” and “Fermenter” are basically the same thing.

The crystallization process in the pharmaceutical industry

Jongia Mixing Technology has initiated numerous mixing processes all over the world using her agitators. In some of these mixing processes, crystallization was a key factor in acquiring the desired final product. The process of crystallization is well-known in the

Jongia supplies agitators for expansion of Mades

Mades is a leading manufacturer of personal care products such as shampoos and lotions. The products are sold all over the world. The company has been growing rapidly for some time, so expansion of the production capacity was badly needed.