A Technical Guide by Jongia Mixing Technology

Core Function

High-speed dispersers excel at three critical tasks:

- Fracturing powder agglomerates into fine particles

- Creating uniform powder distribution throughout liquid mediums

- Facilitating complete dissolution of soluble materials

Operating Principles

High-speed dispersers transform rotational energy into mixing power through a specialized mechanism:

The system centers around a disc-mounted blade at the shaft base, rotating at precisely calculated velocities. This rotation creates a measurable tip speed (peripheral velocity = 3.14 × diameter (m) × RPM).

As the disc spins, it generates powerful suction forces, pulling materials toward the mixing zone. The rotation creates dual vortices—above and below the disc—where intense energy transfer occurs upon material contact with the blade.

This energy transfer creates dramatic velocity differentials throughout the mixture, generating shear forces that tear material layers apart.

Disperser Categories

High-Shear Models:

- Operate at maximum blade velocity

- Generate intense mixing energy

Moderate-Shear Models:

- Run at approximately 50% standard blade speed

- Feature enlarged teeth for enhanced fluid movement

- Require only one-third the power input of high-shear variants

- Still demand triple the energy of conventional agitators

Dispersers vs. Agitators: Choosing Wisely

Dispersers generate sufficient shear force to break apart powder structures—a capability standard agitators lack. While agitators effectively maintain already-dispersed mixtures, they cannot overcome the binding forces holding agglomerates together.

The key difference: agitators sustain dispersions but cannot create them.

Performance Boundaries

A disperser’s effectiveness depends on material properties:

- Excessive viscosity prevents material circulation between blade and tank wall

- Insufficient viscosity fails to generate adequate layer separation

- Adhesive materials disrupt proper flow patterns

Optimal performance creates a distinctive toroidal (doughnut-shaped) flow pattern with the blade positioned at the center void.

Engineering Solutions

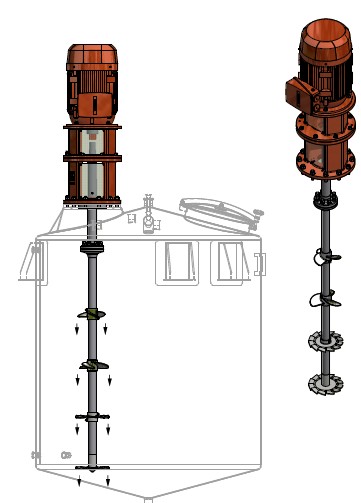

- Additional agitation mechanisms can improve material delivery to the disperser blade

- Multi-shaft systems combine slow-moving wall scrapers for bulk movement with high-speed disperser elements for shear generation

Sizing Considerations

Power Requirements

- Measured in kilowatts (kW)

- Correlates with blade dimensions and expected material resistance

- Power demand increases exponentially with blade diameter Example: Doubling blade diameter from 30cm to 60cm might increase power requirements fivefold (15kW to 75kW)

- Larger blades significantly increase material throughput

Variables Affecting Power Needs

- Blade and tank dimensions

- Processing volume

- Material flow characteristics

- Viscosity profile

- Material density

Tank Design Essentials

Optimal manufacturing vessels feature:

- Height slightly exceeding width

- Curved or bowl-shaped bottoms preventing material accumulation

- Centered drainage points for complete evacuation

- Flush-mounted discharge valves for efficient emptying and cleaning

Blade Selection Parameters

Blade configuration depends on:

- Material flow behavior

- Required dispersion intensity

Our History

From the moment Jongia was founded in 1937 we have been evolving structurally over the years. Learn more about our company’s history with the summary of most important moments highlighted in a timeline.

Blade-to-Tank Ratio Guidelines

- Dense, flowable pastes: 0.5:1

- Standard materials (like paint): 0.33:1

- Low-viscosity formulations: as low as 0.125:1

Practical application: A 1.8-meter tank using the 0.33:1 ratio requires a 0.6-meter blade

Maintenance Indicators

- Well-formulated batches should achieve maximum dispersion within 20-30 minutes after final ingredient addition

- Extended processing rarely improves dispersion quality and may increase thermal load

- Increasing batch times often indicate blade wear

- Replace sawtooth blades when tips wear to 50% of original height

Performance Optimization

Formulation Strategy

- Material addition sequence dramatically impacts results

- Best practice: Add approximately half of total powders rapidly into the liquid vehicle

- Introduce remaining powders with progressively decreasing speed

- Adjust blade speed from 50% of final tip speed initially, increasing to maximum as batch thickens

Operational Parameters

- Optimal performance indicator: toroidal flow pattern

- Target blade tip speed: approximately 1525 meters/minute for medium viscosity (1,500-5,000 centipoises)

- Reduce tip speeds for higher-viscosity materials

- Increase tip speeds for lower-viscosity materials

- Shear intensity correlates directly with blade-tip speed and material rheology

Performance Optimization Checklist

- Begin with thoroughly cleaned equipment

- Verify correct blade-to-tank proportions

- Follow engineered formulation protocols

- Select appropriate blade design in optimal condition

- Operate at maximum suitable blade-tip velocity

- Ensure tank geometry meets requirements

- Supply sufficient power capacity

- Implement proper material addition techniques

- Maintain appropriate rheological parameters

Critical Safety Protocols

- Review all operational and safety documentation from Jongia Mixing Technology

- Ensure comprehensive operator training on equipment use and hazard awareness

- Operation permitted only with all safety systems functional:

- Mixing shaft protective guards

- Tank holder with integrated limit switch

- Lift limit switches preventing operation when blade/shaft is accessible

Critical Warning: High-speed dispersers combine extreme power with rapid movement. Momentary inattention can result in severe or fatal incidents. Never compromise safety protocols for operational convenience.

Related News

VVTI Biogas Tilburg

VTTI Biogas Tilburg is developing a new bio-energy facility, focusing on processing organic waste. The plant is expected to produce approximately 23 million cubic metres of biogas annually. A portion of this will be converted into green gas for the

Homogenization and Cooling in Diary Cream Production

Utilizing Jongia’s Cup Mixer Homogenization is a standard procedure employed in dairy cream production to ensure the consistent distribution of fat globules in both milk and cream. This process, achieved through a high-pressure homogenization apparatus, breaks down and disperses fat

Tutorial: Rushton Turbine vs Concave Turbine

We are happy to announce on behalf of Jongia Mixing Technology that we have just launched a new tutorial on our website! This time, we take you into the world of mixing technology with an in-depth comparison between the “Rusthon