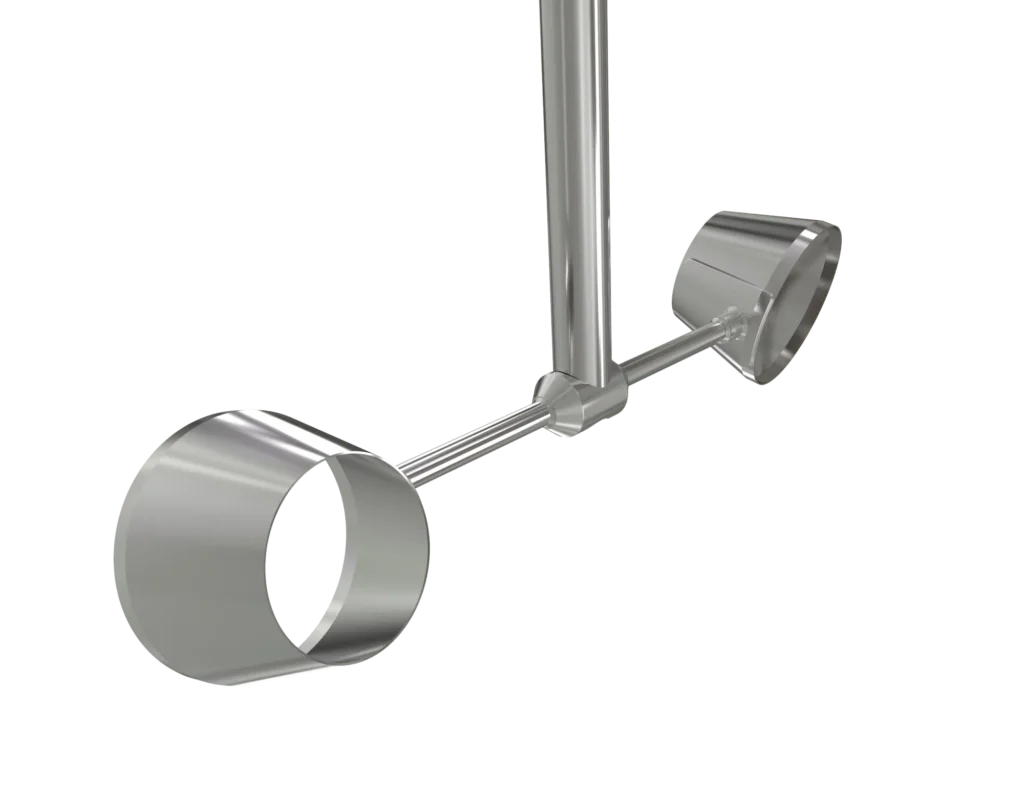

A number of viscous – thick liquid – products that need to be mixed can be easily damaged. For these mixing processes cupmixers are used: product friendly stirring elements that are placed horizontally in the tank. Jongia has unique cupmixers in its range with two, three or four cups, depending on the purpose.

How does the cupmixer function?

A cupmixer is the stirring element used, for example, in the viscous product: cream. This is mainly because cream is sensitive to shear. A cumixer pumps out radially. This means that it is placed horizontally in the tank. Due to its shape, it creates a slight underpressure, which lifts the product so that any powders are pulled up from the bottom of the thank, into the cup. The cupmixer has a larger orifice than the intake one. This gives a form of acceleration and subsequently a suction effect. What is important for cream, for example, is that no air is drawn into the tank. The cupmixer does not do this, as it pumps out radially and horizontally. This is an important difference with other agitators.

Multiple stirring elements in a tank

Because the cupmixer cannot generate axial transport through the tank, several cup sets are sometimes attached above one another to the stirring shaft in order to create a throughput from one element to the other. Another possibility is to place another element above the cupmixer, for example a propeller that feeds the cupmixer. This, however, depends on the length of the shaft and on the size of the tank.

The cupmixer can be placed quite deep in the tank, as it has no downward thrust. An advantage of this is that it is almost bottom-following. Another advantage is that when the level of the products to be mixed drops and passes through the liquid level, it never ‘skates’ on that level. With a normal element, you would then have a dancing effect like a stone over water. The cupmixer, however, scoops through the liquid level. The cupmixer can be placed centrally or de-centrally in the tank, depending on the viscosity.

How it works

The cupmixer is a special stirring element. It is used in the mixing process of viscous products. The cupmixer is also suited for sensitive viscous products that are easily damaged. A cupmixer is placed in the tank horizontally and can have one or more cup sets placed above each other on the stirring shaft in order to create a throughput from one cup element to the other. In order to provide a visual explanation of the operation of the cupmixer, we have included a tutorial. Check it out below!

Want to know more?

As with all production processes, mixing viscous liquids requires a specific approach and a suitable agitator. Jongia has the knowledge and experience to advise you in this field. Do you have any questions? Please do not hesitate to contact us.

Contact our specialized team for all your questions

Tom Pruymboom

Sales Director

Area Worldwide

Bart Brouwer

Area Sales Manager

Area Worldwide

Technical Questions?

Sijko van der Veen

Application Engineer

Technical Specialist

Tutorial: Batch Crystallization

Jongia Mixing Technology has initiated countless mixing processes all over the world with the help of her agitators. In a number of these mixing processes, crystallization is of great importance to obtain the desired final product. In this tutorial, Area

The cupmixer: from request to solution

The cupmixer is a stirring element that can be widely deployed. It can therefore be used in a variety of industries. Nevertheless, a cupmixer is primarily used for mixing products for which it is important that no air is entrapped and that homogenous quality

Tutorial: How does the cupmixer work?

The cupmixer is a special stirring element. It is used in the mixing process of viscous products. The cupmixer is also suited for sensitive viscous products that are easily damaged. A cupmixer is placed in the tank horizontally and can