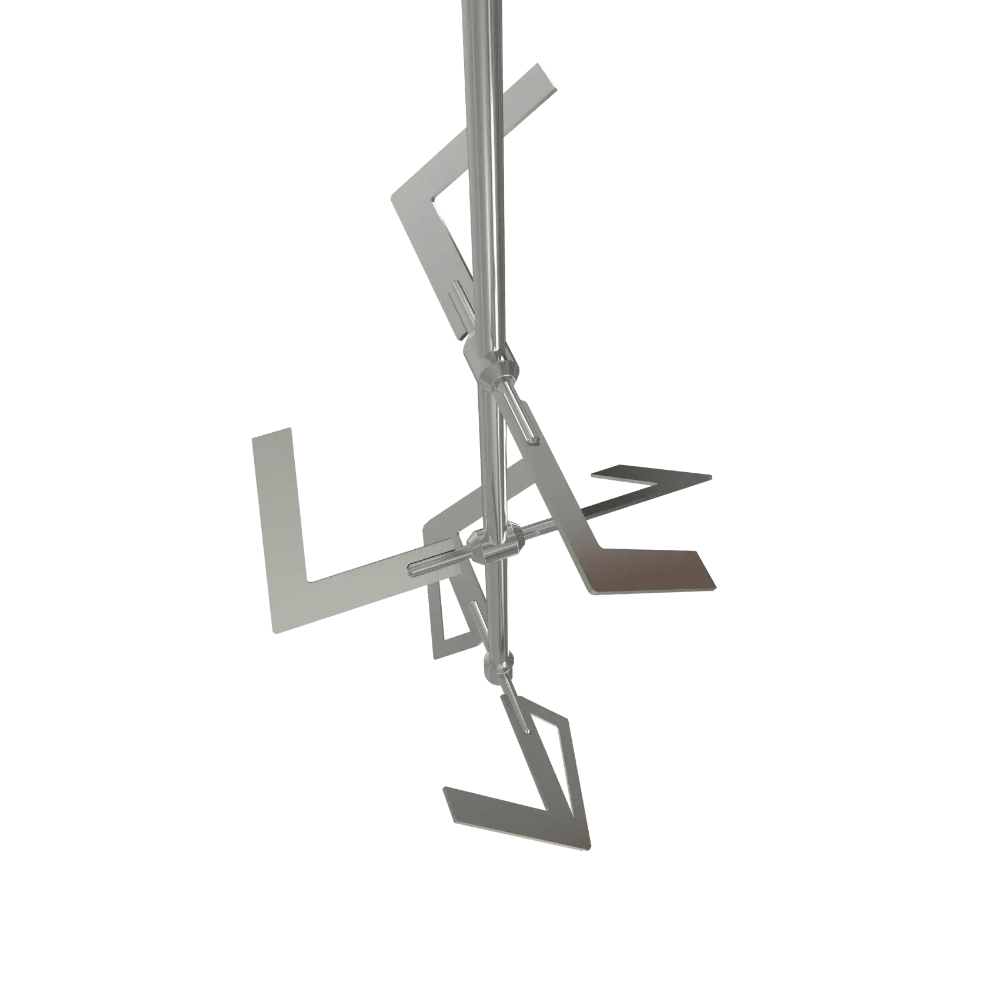

Arms and legs, a ribbon, a combination of an anchor and an axial flow turbine… What is not said about the UZ mixing element? Obviously, if the UZ mixing element has a very recognizable shape, then it must also be a very special mixing element.

And so it is!

The UZ mixing element contains the following properties:

- It can Thrust, Scoop and Pump.

- This is ideal for medium viscous liquids

- It has a constant power input regardless of the liquid level

- It is characterized by a large ratio between mixing element diameter and tank diameter

- It is usually positioned decentralized and does not require baffles

- Because of the low required rotations, it is also used on fragile products

- The tip speed is low, the shear is low, because of the shape and therefore there is also a relatively low power consumption as a result

- The arms and legs cover almost the entire cylinder that the agitator occupies

- Ideal for use during tank emptying and filling, this agitator can just keep running on the liquid level

- It is a good alternative for the “Gate” agitator element

- Despite the fairly large surface of the agitator elements, it is easy to clean due to its shape, as there are virtually no blind spots in Jongia Mixing Technology’s design

- It is often used in the dairy industry, such as for yogurt or pro-biotic drinks

The entire agitator can be inserted through the agitator flange and manhole to be built up later in the tank.

This also makes this agitator perfectly suitable for installation on site, without interruption for the tank builder.

Of course, the mixing elements are made fully sanitary by Jongia, as the so-called pin construction is applied here. See the example shown below.

With the UZ mixing element, Jongia has a perfect product in its product portfolio for your delicate products, such as yogurt, cottage cheese, pro-biotics, enzymes, lecitines, fruit juice concentrates, Skyr and yogurt cultures.

Because the complete layout of the different UZ mixing elements must be a reliable and high quality construction that is easy to clean and must be able to provide years of performance, Jongia applies to these agitators the most reliable agitator drive units that guarantee years of performance and uptime. The shaft is always solid material and polished, just as the UZ elements are also highly polished for perfect cleanability and hygienic design.

Want to know more about Jongia ‘s UZ mixing element or other mixing elements from Jongia Mixing Technology?

Feel free to visit the website to read more about our Mixing Elements. Or feel free to contact us at info@jongia.com

We are happy to talk to you about the most challenging mixing solutions!

Contact our specialized team for all your questions

Bart Brouwer

Area Sales Manager

Area Worldwide

Tom Pruymboom

Sales Director

Area Worldwide

Related Articles

High-Speed Disperser Technology: The Engineering Behind Effective Mixing

A Technical Guide by Jongia Mixing Technology Core Function High-speed dispersers excel at three critical tasks: Fracturing powder agglomerates into fine particles Creating uniform powder distribution throughout liquid mediums Facilitating complete dissolution of soluble materials Operating Principles High-speed dispersers transform

VVTI Biogas Tilburg

VTTI Biogas Tilburg is developing a new bio-energy facility, focusing on processing organic waste. The plant is expected to produce approximately 23 million cubic metres of biogas annually. A portion of this will be converted into green gas for the

Homogenization and Cooling in Diary Cream Production

Utilizing Jongia’s Cup Mixer Homogenization is a standard procedure employed in dairy cream production to ensure the consistent distribution of fat globules in both milk and cream. This process, achieved through a high-pressure homogenization apparatus, breaks down and disperses fat