Axial Flow Turbine Mixing Element

In order to provide a visual explanation of the operation of the Axial Flow Turbine, we have included a video tutorial. Check it out below!

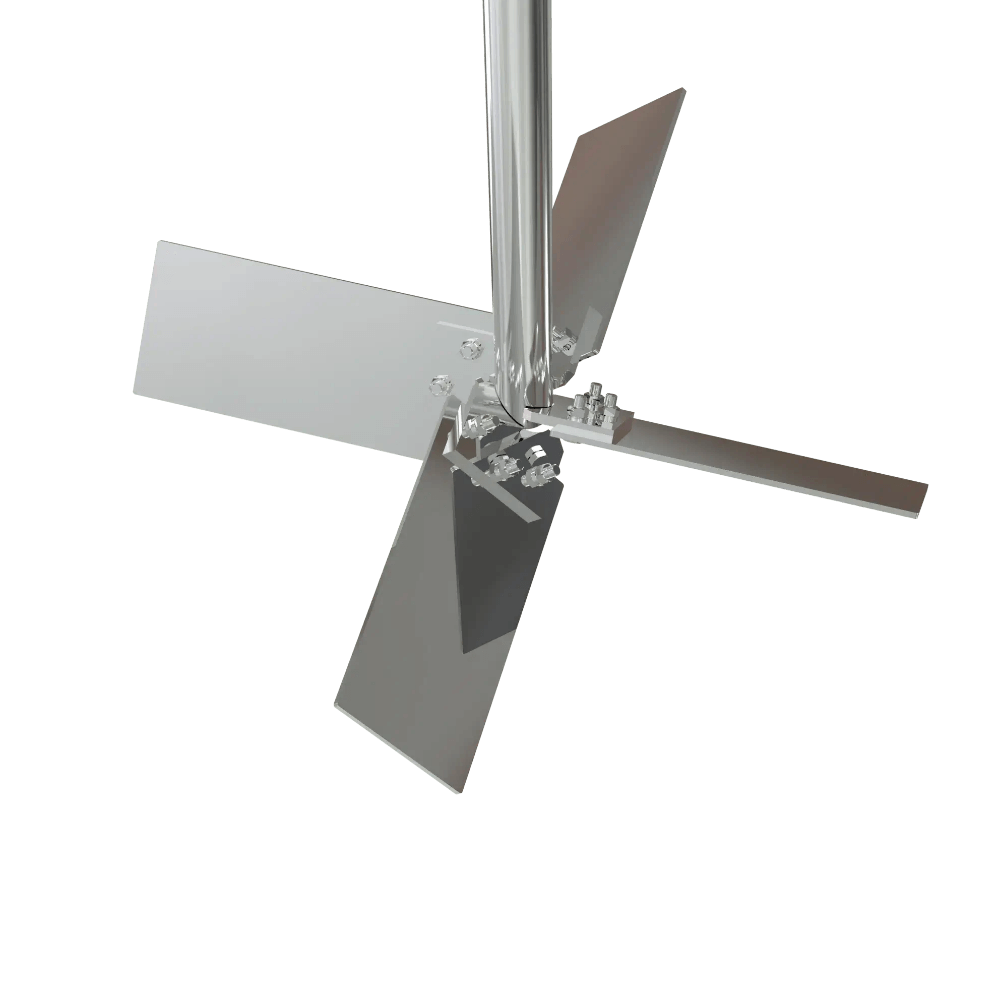

Axial Flow Turbine Bolted

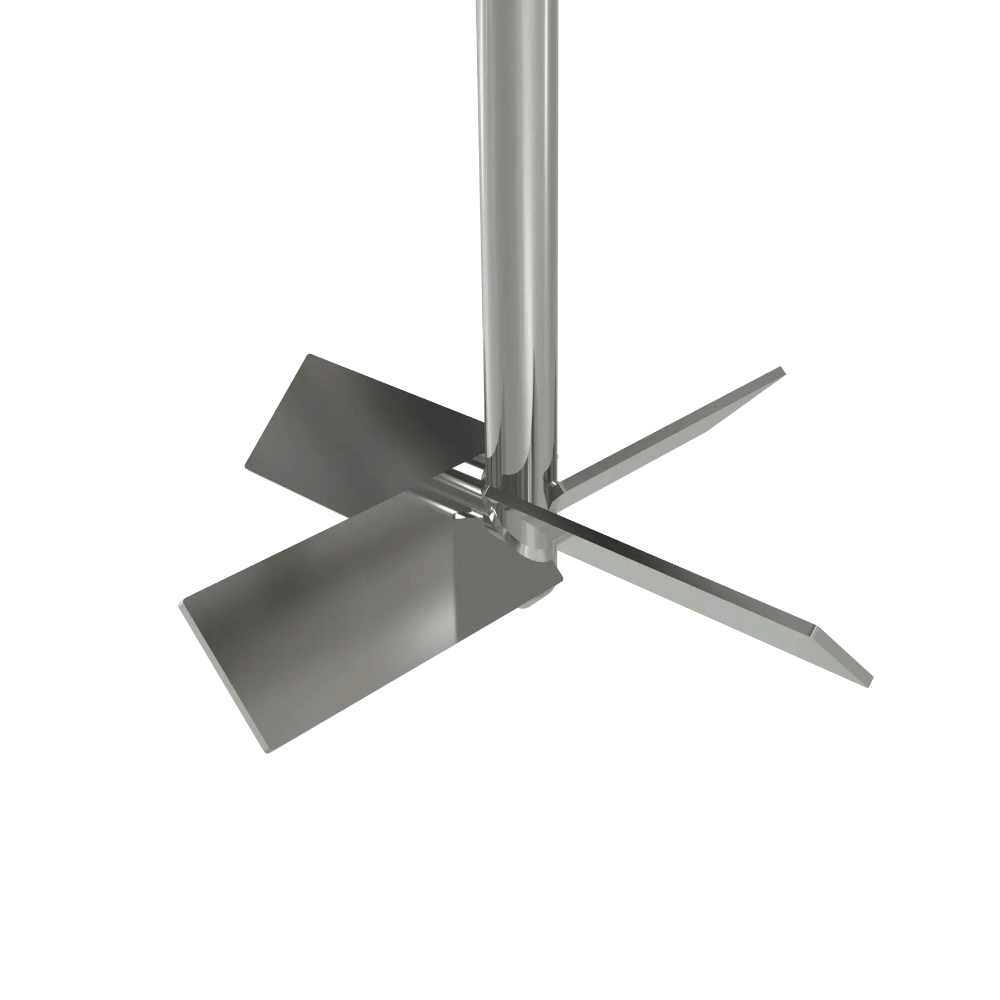

Axial Flow Turbine Welded

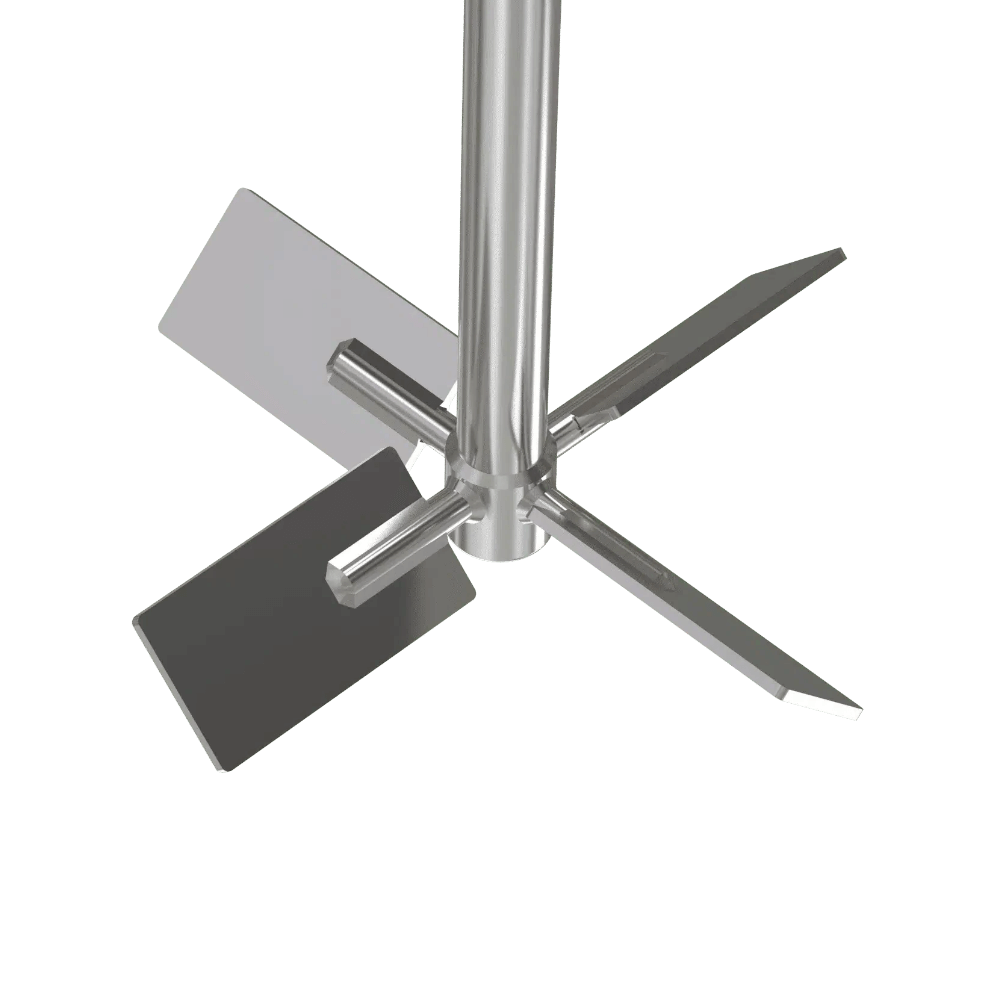

Axial Flow Turbine Pin

Tutorial Axial Flow Turbine

In this tutorial, Commercial Director Tom Pruymboom shows you the process of starch gelatinization using a labscale test unit. In it, raw starch is dissolved in 10 liters of water and the mixture is then heated using a heating coil. When it has become a gel, enzymes are added to convert the mixture to glucose. The mixing is done by a mixer shaft equipped with a 2-blade residual stirrer, a 4-blade Axial Flow turbine and a Hydroprop mixing element for a top-over-bottom stirring process with axial flow.

Frequently Asked Questions

What is the purpose of the Axial Flow Turbine?

The Axial Flow Turbine is designed to enhance mixing processes by using axial flow to achieve efficient and homogeneous fluid movement. It is especially effective in applications requiring thorough mixing of viscous materials.

Where can I find a visual explanation of the Axial Flow Turbine?

A video tutorial explaining the operation of the Axial Flow Turbine is available on our website. You can check it out below for a detailed visual guide.

What materials are used in the construction of the Axial Flow Turbine?

The Axial Flow Turbine can be constructed using various materials, depending on the specific application requirements, to ensure durability and performance. Common options include stainless steel and other corrosion-resistant materials.

How does the mixing element work in the Axial Flow Turbine?

The mixing element operates by utilizing a combination of blades that create axial flow. This design enhances fluid circulation and promotes efficient mixing, particularly when working with complex formulations.

Are there different configurations of the Axial Flow Turbine?

Yes, the Axial Flow Turbine is available in multiple configurations, including bolted and welded designs, allowing customization based on operational needs and installation requirements.

Related Articles

The Double Acting Axial Flow Turbine type AST-MTE mixing element

Operation of an AST-MTE Element Operation of an AST-MTE Element This element can be used in both CW (clockwise) and CCW (counterclockwise) directions. In one case, the inner AST element is downward-pumping with the outer tips pumping upward, and in

High-Speed Disperser Technology: The Engineering Behind Effective Mixing

A Technical Guide by Jongia Mixing Technology Core Function High-speed dispersers excel at three critical tasks: Fracturing powder agglomerates into fine particles Creating uniform powder distribution throughout liquid mediums Facilitating complete dissolution of soluble materials Operating Principles High-speed dispersers transform

VVTI Biogas Tilburg

VTTI Biogas Tilburg is developing a new bio-energy facility, focusing on processing organic waste. The plant is expected to produce approximately 23 million cubic metres of biogas annually. A portion of this will be converted into green gas for the