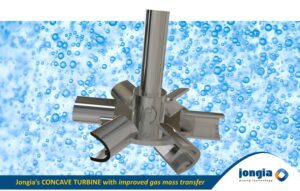

Concave Turbine Mixing Element

The shape of the Concave turbine enabled fluids and gasses to be mixed together, dispersed without the mixing element becoming unstable. This is due to the fact that is has a radial flow and is self-balancing. The “Channels” of this mixing element ensure that the gas flow is equally dispersed in the vessel.

The flow is discharged radially outward to the vessel wall with half the flow directed upward, and half the flow directed downward.

Frequently Asked Questions

What is the shape of the Concave turbine mixing element?

The Concave turbine mixing element features a unique concave shape that effectively enables the mixing and dispersion of fluids and gases without becoming unstable. This design leads to radial flow and self-balancing properties that enhance mixing efficiency.

How does the mixing element ensure gas flow dispersion?

The mixing element has specially designed “Channels” that facilitate equal dispersion of gas flow within the vessel. This ensures that the gas is distributed uniformly, optimizing the mixing process and improving overall reaction efficiency.

What direction does the flow get discharged in the Concave turbine?

The flow from the Concave turbine is discharged radially outward towards the vessel wall. It is designed to direct half of the flow upward and the other half downward, which promotes effective mixing in the vessel.

What are the main benefits of using the Concave turbine?

The main benefits include enhanced mixing stability due to its self-balancing nature, efficient gas dispersion, and the ability to mix fluids and gases effectively without compromising element stability. This leads to improved performance in various applications.

Where can I find a visual representation of the Concave turbine?

A visual representation of the Concave turbine can be found in a 3D render. The interactive model offers an engaging way to understand its design and functionality, showcasing its unique features and flow characteristics.

Contact our specialized team for all your questions

Tom Pruymboom

Sales Director

Area Worldwide

Bart Brouwer

Area Sales Manager

Area Worldwide

Related Articles

Concave Turbine with improved stability and performance

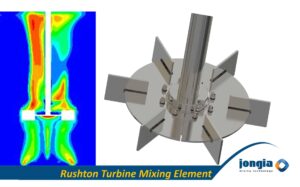

Concave turbines are often called “the next generation” turbines as they significantly perform better compared to conventional “Rushton” turbines. However, in most all engineering books and studies, the one and only turbine in which is referred to, is the Rushton

Fermentation & Bioreactor Mixing Process

Bioreactors and Fermenters are culture systems to produce cells or organisms. They are used in various applications, including basic research and development, and the manufacturing of biopharmaceuticals, food and food additives, chemicals, and other products. A broad range of cell types and organisms can be cultivated in bioreactors and Fermenters, including cells (like mammalian cell lines, insect cells, and stem cells), microorganisms (like bacteria, yeasts, and fungi), as well as plant cells and algae. The words “Bioreactor” and “Fermenter” are basically the same thing.

Meet Jongia’s Rushton Turbine for Gas-Liquid & Fermentation process applications

The Rushton disc turbine or Rushton turbine is a radial flow impeller used for many mixing applications and particularly for Gas Dispersion and Fermentation applications in process engineering and was invented by John Henry Rushton.[1] The design of the Rushton