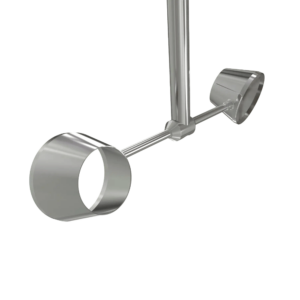

Cup Mixer Element

The cupmixer is a special stirring element. It is used in the mixing process of viscous products. The cupmixer is also suited for sensitive viscous products that are easily damaged. A cupmixer is placed in the tank horizontally and can have one or more cup sets placed above each other on the stirring shaft in order to create a throughput from one cup element to the other.

In order to provide a visual explanation of the operation of the cupmixer, we have included a video tutorial. Check it out below!

Frequently Asked Questions

What is a cupmixer?

A cupmixer is a specialized stirring element designed for mixing viscous products. Its unique design makes it ideal for sensitive materials that may be easily damaged during the mixing process. The cupmixer operates horizontally within the tank, accommodating multiple cup sets for efficient mixing.

How does the cupmixer work?

The cupmixer operates by rotating one or more cup sets positioned on a stirring shaft. This design enables seamless throughput from one cup element to another, ensuring effective mixing of viscous materials while minimizing damage to sensitive products. Check out our video tutorial for a visual explanation!

Can the cupmixer be used for all types of products?

The cupmixer is specifically optimized for viscous and sensitive products. While it excels in these applications, it may not be suitable for all product types. For best results, consider the properties of your specific material before using a cupmixer.

Is there a tutorial available for the cupmixer?

Yes, there is a video tutorial available that visually explains how the cupmixer operates. This resource is perfect for those looking to understand its functionality and benefits better. You can watch the tutorial on our website.

Where can I find more videos about cupmixers?

You can find an extensive collection of cupmixer videos on our website. These videos showcase different models, comparisons with other mixers, and further demonstrations. Explore our video section for more insights into cupmixer applications and performance.

Related Articles

The Double Acting Axial Flow Turbine type AST-MTE mixing element

Operation of an AST-MTE Element Operation of an AST-MTE Element This element can be used in both CW (clockwise) and CCW (counterclockwise) directions. In one case, the inner AST element is downward-pumping with the outer tips pumping upward, and in

High-Speed Disperser Technology: The Engineering Behind Effective Mixing

A Technical Guide by Jongia Mixing Technology Core Function High-speed dispersers excel at three critical tasks: Fracturing powder agglomerates into fine particles Creating uniform powder distribution throughout liquid mediums Facilitating complete dissolution of soluble materials Operating Principles High-speed dispersers transform

VVTI Biogas Tilburg

VTTI Biogas Tilburg is developing a new bio-energy facility, focusing on processing organic waste. The plant is expected to produce approximately 23 million cubic metres of biogas annually. A portion of this will be converted into green gas for the

Contact our specialized team for all your questions

Tom Pruymboom

Sales Director

Area Worldwide