Dispersion Turbine Mixing Element

Core Function

High-speed dispersers excel at three critical tasks:

- Fracturing powder agglomerates into fine particles

- Creating uniform powder distribution throughout liquid mediums

- Facilitating complete dissolution of soluble materials

As the disc spins, it generates powerful suction forces, pulling materials toward the mixing zone. The rotation creates dual vortices—above and below the disc—where intense energy transfer occurs upon material contact with the blade.

This energy transfer creates dramatic velocity differentials throughout the mixture, generating shear forces that tear material layers apart.

Performance Boundaries

A disperser’s effectiveness depends on material properties:

- Excessive viscosity prevents material circulation between blade and tank wall

- Insufficient viscosity fails to generate adequate layer separation

- Adhesive materials disrupt proper flow patterns

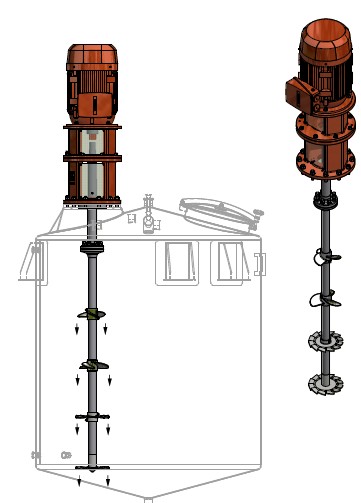

Optimal performance creates a distinctive toroidal (doughnut-shaped) flow pattern with the blade positioned at the center void.

Engineering Solutions

- Additional agitation mechanisms can improve material delivery to the disperser blade

- Multi-shaft systems combine slow-moving wall scrapers for bulk movement with high-speed disperser elements for shear generation

Tank Design Essentials

Optimal manufacturing vessels feature:

- Height slightly exceeding width

- Curved or bowl-shaped bottoms preventing material accumulation

- Centered drainage points for complete evacuation

Formulation Strategy

- Material addition sequence dramatically impacts results

- Best practice: Add approximately half of total powders rapidly into the liquid vehicle

- Introduce remaining powders with progressively decreasing speed

- Adjust blade speed from 50% of final tip speed initially, increasing to maximum as batch thickens

High-Speed Disperser Technology: The Engineering Behind Effective Mixing

A Technical Guide by Jongia Mixing Technology Core Function High-speed dispersers excel at three critical tasks: Fracturing powder agglomerates into fine particles Creating uniform powder distribution throughout liquid mediums Facilitating complete dissolution of soluble materials Operating Principles High-speed dispersers transform

Frequently Asked Questions

What are the core functions of a high-speed disperser?

High-speed dispersers excel at fracturing powder agglomerates, creating uniform powder distribution in liquids, and facilitating complete dissolution of soluble materials. The spinning disc generates suction forces, creating dual vortices where intense energy transfer occurs, leading to shear forces that help break apart material layers.

How does the performance of a disperser depend on material properties?

A disperser’s effectiveness can be limited by material properties such as excessive viscosity, which hampers circulation, and insufficient viscosity, which fails to achieve adequate layer separation. Adhesive materials can also disrupt flow patterns, affecting overall mixing efficiency.

What is the optimal flow pattern for a disperser?

The optimal performance of a disperser results in a distinctive toroidal (doughnut-shaped) flow pattern, with the disperser blade positioned at the center. This flow pattern is essential for maximizing mixing efficiency and achieving desired material dispersion.

How can engineering solutions improve disperser performance?

Additional agitation mechanisms can enhance material delivery to the disperser blade. Multi-shaft systems that combine slow-moving wall scrapers for bulk movement and high-speed disperser elements for shear generation can optimize mixing outcomes and improve overall efficiency.

What tank design essentials should be considered for optimal dispersing?

Ideal manufacturing vessels should have a height slightly greater than their width and feature curved or bowl-shaped bottoms to prevent material accumulation. Centered drainage points are also important for ensuring complete material evacuation after mixing is complete.

Contact our specialized team for all your questions

Tom Pruymboom

Sales Director

Area Worldwide

Bart Brouwer

Area Sales Manager

Area Worldwide

Related Articles

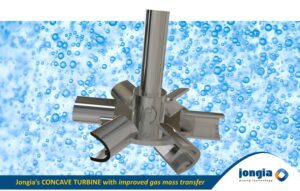

Concave Turbine with improved stability and performance

Concave turbines are often called “the next generation” turbines as they significantly perform better compared to conventional “Rushton” turbines. However, in most all engineering books and studies, the one and only turbine in which is referred to, is the Rushton

Fermentation & Bioreactor Mixing Process

Bioreactors and Fermenters are culture systems to produce cells or organisms. They are used in various applications, including basic research and development, and the manufacturing of biopharmaceuticals, food and food additives, chemicals, and other products. A broad range of cell types and organisms can be cultivated in bioreactors and Fermenters, including cells (like mammalian cell lines, insect cells, and stem cells), microorganisms (like bacteria, yeasts, and fungi), as well as plant cells and algae. The words “Bioreactor” and “Fermenter” are basically the same thing.

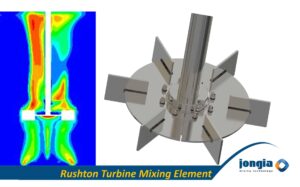

Meet Jongia’s Rushton Turbine for Gas-Liquid & Fermentation process applications

The Rushton disc turbine or Rushton turbine is a radial flow impeller used for many mixing applications and particularly for Gas Dispersion and Fermentation applications in process engineering and was invented by John Henry Rushton.[1] The design of the Rushton