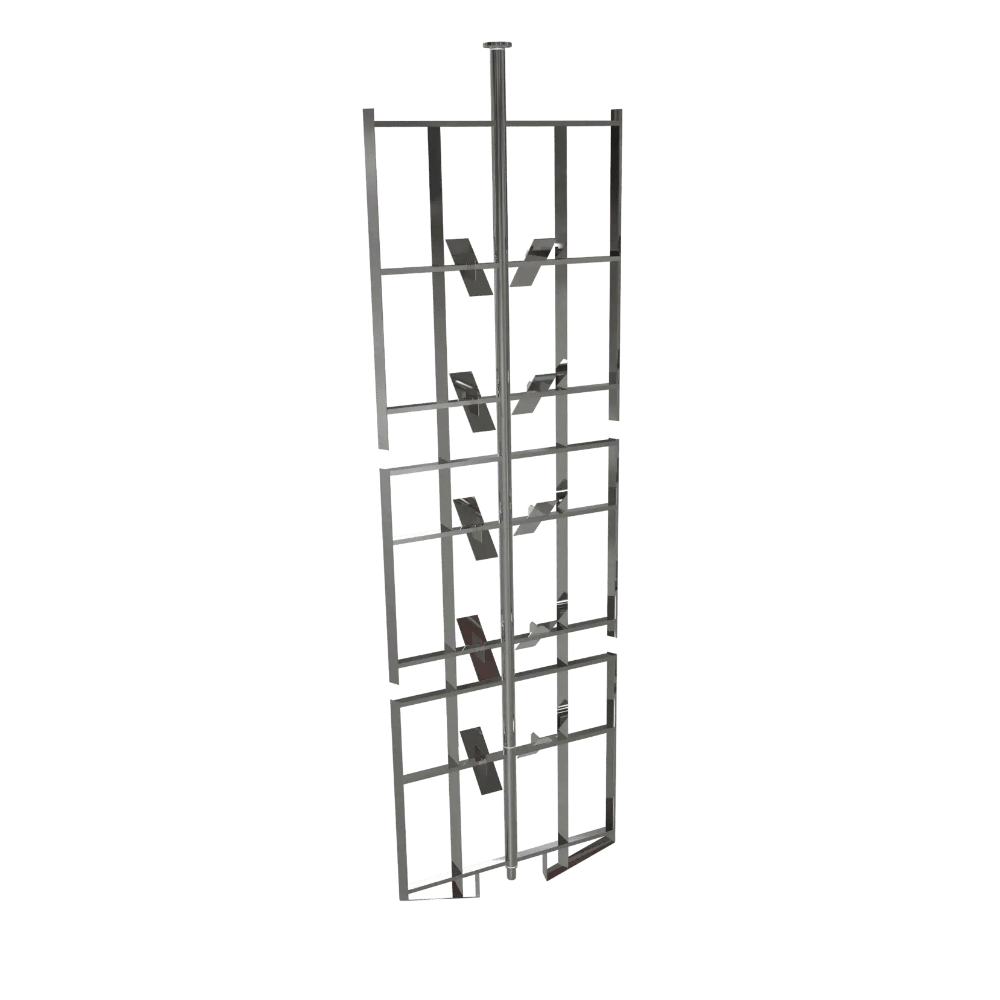

Gate Mixing Element

Frequently Asked Questions

What is the Gate Mixing Element used for?

The Gate Mixing Element is designed for mixing liquids efficiently in various industrial applications. It ensures thorough blending, enhancing the quality of the final product and optimizing production processes.

What industries can benefit from this element?

Various industries, including chemical, food and beverage, and pharmaceuticals, can benefit from the Gate Mixing Element for their mixing needs. Its versatility makes it suitable for a range of applications.

How does the Gate Mixing Element improve mixing efficiency?

The Gate Mixing Element optimizes flow patterns and reduces dead zones, which leads to improved mixing efficiency. This results in a more consistent product and reduces processing time and energy consumption.

Is the Gate Mixing Element easy to install?

Yes, the Gate Mixing Element is designed for easy installation in existing setups. Its compatibility with various systems ensures a smooth integration process, leading to minimal downtime during installation.

What maintenance is required for the Gate Mixing Element?

Regular inspections and cleaning are recommended to ensure optimal performance of the Gate Mixing Element. Following manufacturer guidelines will help prolong its lifespan and maintain mixing efficiency.

Related Articles

The Double Acting Axial Flow Turbine type AST-MTE mixing element

Operation of an AST-MTE Element Operation of an AST-MTE Element This element can be used in both CW (clockwise) and CCW (counterclockwise) directions. In one case, the inner AST element is downward-pumping with the outer tips pumping upward, and in

High-Speed Disperser Technology: The Engineering Behind Effective Mixing

A Technical Guide by Jongia Mixing Technology Core Function High-speed dispersers excel at three critical tasks: Fracturing powder agglomerates into fine particles Creating uniform powder distribution throughout liquid mediums Facilitating complete dissolution of soluble materials Operating Principles High-speed dispersers transform

VVTI Biogas Tilburg

VTTI Biogas Tilburg is developing a new bio-energy facility, focusing on processing organic waste. The plant is expected to produce approximately 23 million cubic metres of biogas annually. A portion of this will be converted into green gas for the