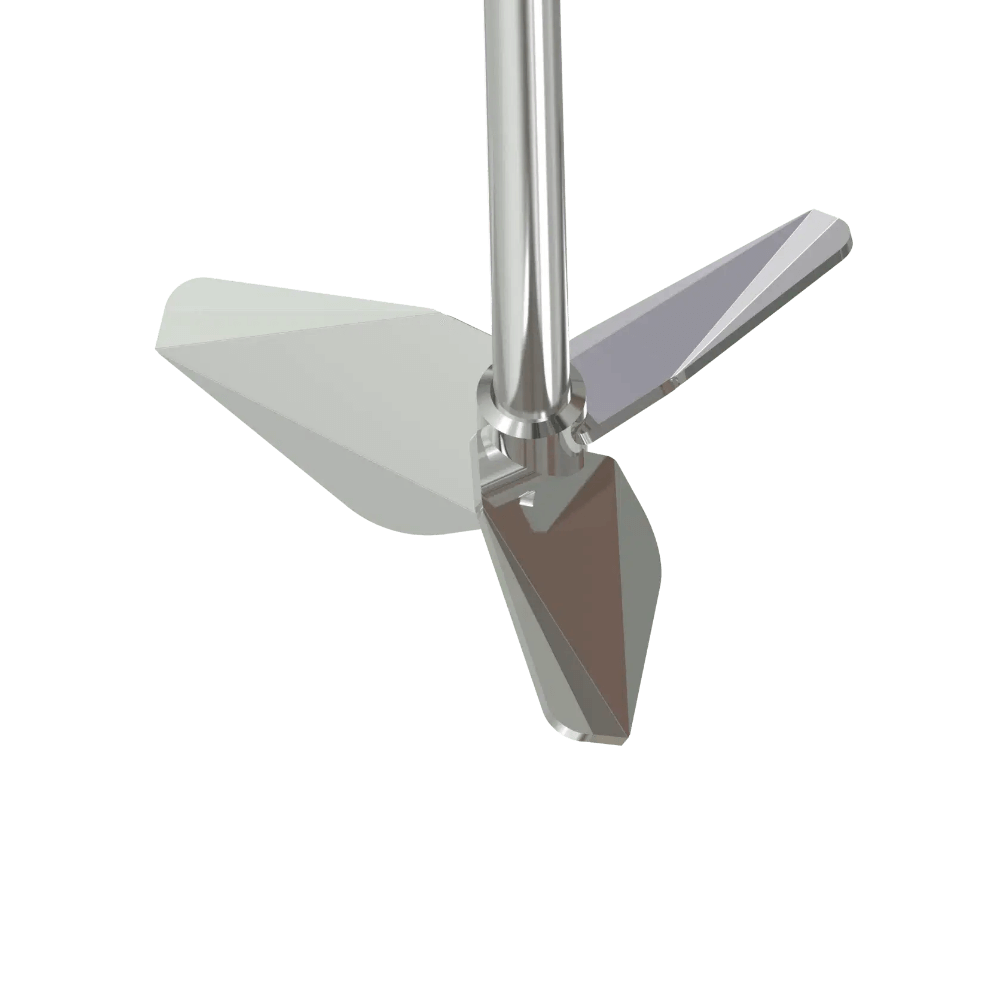

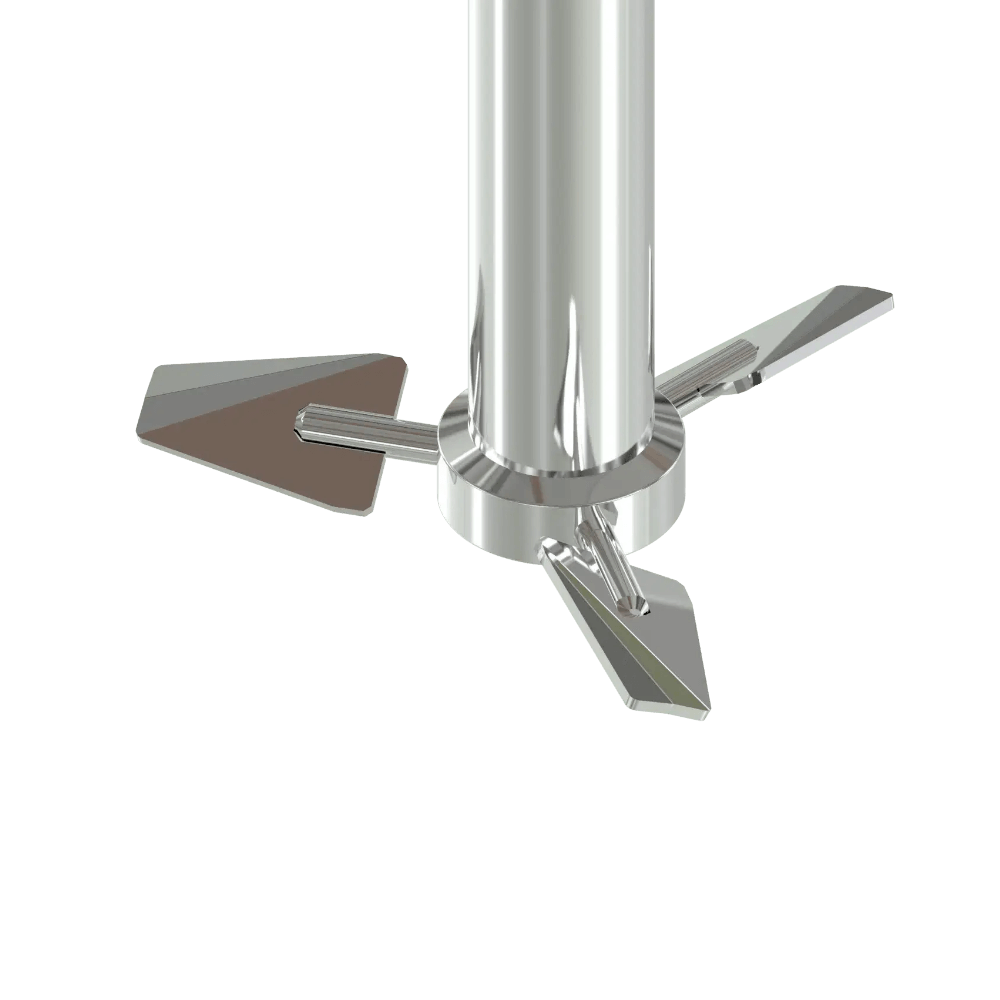

Hydrofoil Mixing Element

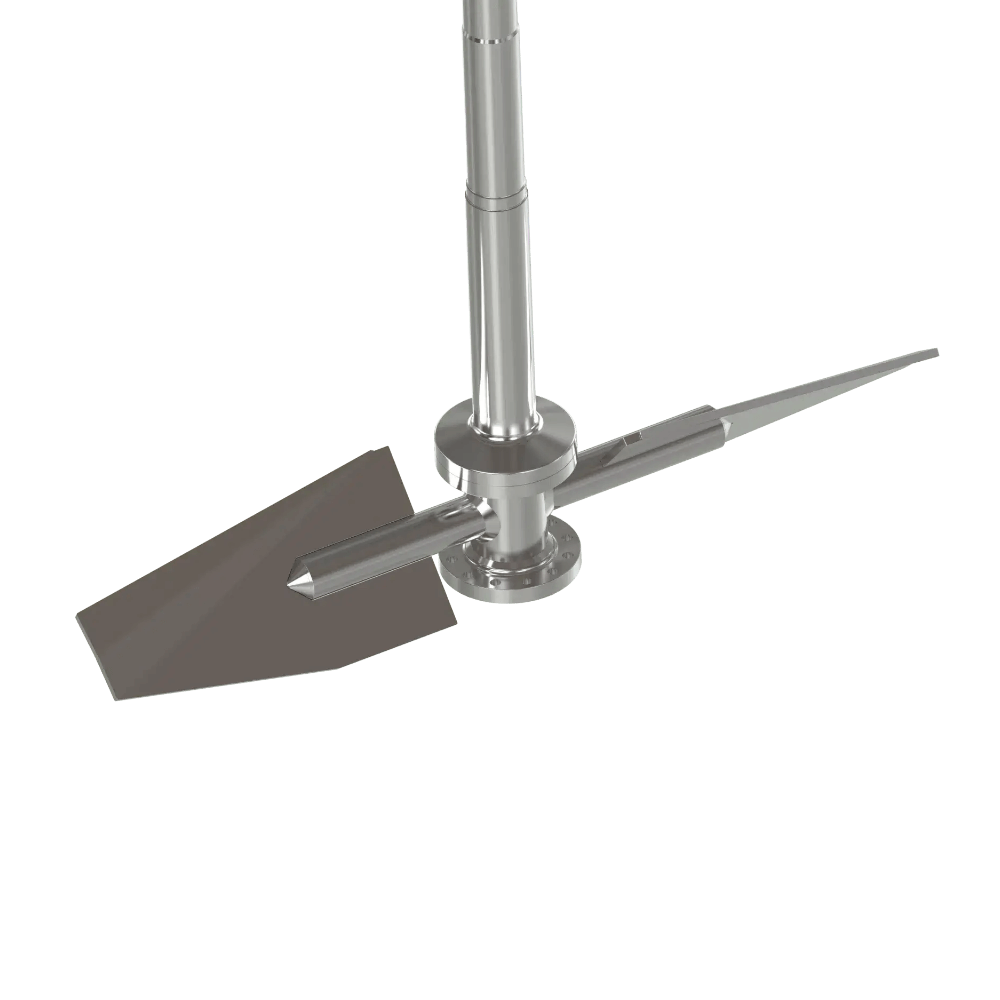

The shape of the Hydrofoil blades designed by Jongia Mixing Technology, in combination with a rest stirrer, create a smooth top over bottom velocity in the tank. Halfway down the agitator shaft, two extra Hydroprops can be applied to increase axial flow.

In most cases, the Hydroprop agitators have a fairly large surface, and the blades are oriented as such that they pump from the top downwards.

In some cases, however, the agitator can be equipped with a set of Hydrofoil blades oriented to pump upwards.

Frequently Asked Questions

What is the Hydrofoil Mixing Element?

The Hydrofoil Mixing Element is designed by Jongia Mixing Technology. Its specialized blade shape, combined with a rest stirrer, enables smooth fluid movement inside a tank. It aims to enhance mixing efficiency and maintain consistent flow patterns throughout the process.

How do Hydrofoil blades function?

Hydrofoil blades are oriented to efficiently pump fluids, primarily moving from the top downwards. This design helps create a balanced flow and improves the mixing process inside tanks, ensuring that materials are adequately blended and homogenized.

Can Hydrofoil blades be customized for specific applications?

Yes, Hydrofoil blades can be customized or oriented to pump fluids upwards based on specific operational needs. This adaptability allows users to achieve optimal mixing results for various applications by modifying the blade configuration accordingly.

What is the benefit of using Hydroprops?

The integration of Hydroprops halfway down the agitator shaft increases axial flow, enhancing mixing performance. This additional feature promotes improved liquid movement, contributing to better overall efficiency in the mixing process while minimizing dead zones within the tank.

Where can I find more information about Hydrofoil Mixing Elements?

Additional information about Hydrofoil Mixing Elements, including videos and articles, can be accessed on the Jongia website. This resource offers comprehensive insights into different mixing technologies, including application specifics and performance benefits for various industrial processes.

Contact our specialized team for all your questions

Tom Pruymboom

Sales Director

Area Worldwide

Bart Brouwer

Area Sales Manager

Area Worldwide

Hydrofoil Articles

The introduction of crystallization in the mixing process for the dairy industry

Jongia Mixing Technology has initiated numerous mixing processes all over the world using her agitators. In some of these mixing processes, crystallization was a key factor in acquiring the desired final product. The process of crystallization is well-known in the

Customized agitators make for a satisfied starch manufacturer

Native starch is used as base material in many applications. Native starches manage texture, control moisture content, and stabilize products, making them the ideal material for food applications. About native starches Native starches are insoluble in cold water and swell

The BioFoil® propeller: an innovative stirring element

For mixing processes in every market Jongia Mixing Technology can recommend the hydrofoil propeller. This is a stirring element that is extremely product-friendly due to its shape. It’s a propeller with many possibilities because of its low energy consumption and