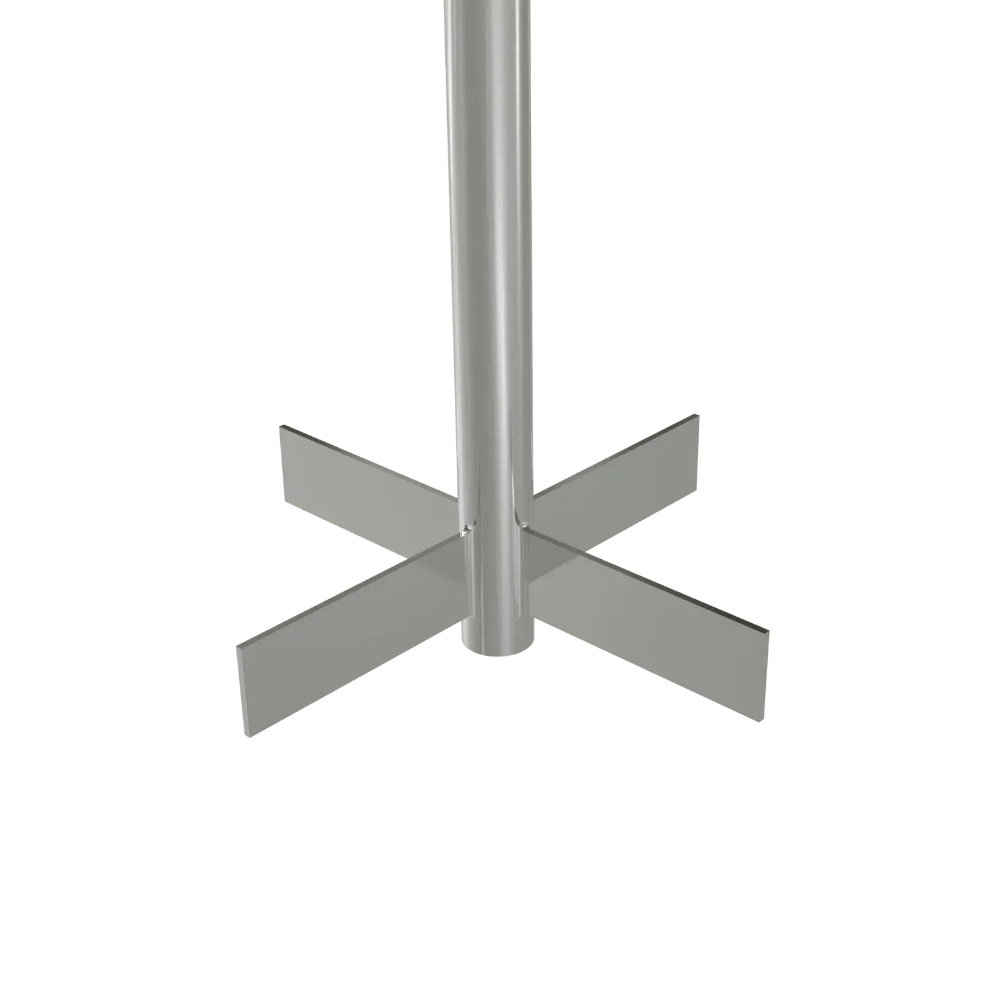

Radial Flow Turbine Element

Frequently Asked Questions

What is a radial flow turbine element?

A radial flow turbine element is a component used in mixing processes, designed to enhance fluid flow and mixing efficiency. Its unique design allows for improved energy transfer and better dispersion of materials within a mixture.

How does a radial flow turbine improve mixing?

The radial flow turbine improves mixing by generating a radial flow pattern, which distributes materials evenly throughout the mixture. This leads to enhanced interaction between components, resulting in quicker and more uniform mixing.

What are the applications of a radial flow turbine?

Radial flow turbines are used in various industries, including food processing, pharmaceuticals, and chemical manufacturing. They are ideal for applications requiring efficient mixing, such as suspensions, emulsions, and homogeneous solutions.

What materials are radial flow turbines made from?

Radial flow turbines are typically constructed from durable materials like stainless steel or specialized plastics that resist corrosion and wear. This ensures longevity and reliability even in harsh processing environments.

Can radial flow turbines be customized?

Yes, radial flow turbines can be customized to meet specific application requirements, such as size, flow rates, and materials. Custom designs can help optimize performance for different mixing tasks and enhance overall operational efficiency.

Related Articles

The Double Acting Axial Flow Turbine type AST-MTE mixing element

Operation of an AST-MTE Element Operation of an AST-MTE Element This element can be used in both CW (clockwise) and CCW (counterclockwise) directions. In one case, the inner AST element is downward-pumping with the outer tips pumping upward, and in

High-Speed Disperser Technology: The Engineering Behind Effective Mixing

A Technical Guide by Jongia Mixing Technology Core Function High-speed dispersers excel at three critical tasks: Fracturing powder agglomerates into fine particles Creating uniform powder distribution throughout liquid mediums Facilitating complete dissolution of soluble materials Operating Principles High-speed dispersers transform

VVTI Biogas Tilburg

VTTI Biogas Tilburg is developing a new bio-energy facility, focusing on processing organic waste. The plant is expected to produce approximately 23 million cubic metres of biogas annually. A portion of this will be converted into green gas for the