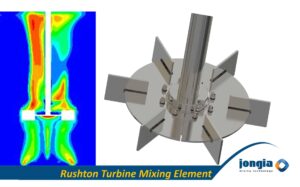

Rushton Turbine Mixing Element

The shape of the Rushton turbine enabled fluids and gasses to be mixed together, dispersed without the mixing element becoming unstable. This is due to the fact that is has a radial flow and is self-balancing.

The flow is discharged radially outward to the vessel wall with half the flow directed upward, and half the flow directed downward.

Frequently Asked Questions

What is the purpose of the Rushton turbine?

The Rushton turbine is designed to effectively mix fluids and gases, ensuring they are dispersed uniformly without instability. Its unique shape enables radial flow and self-balancing properties, resulting in efficient mixing processes.

How does the flow direction work in a Rushton turbine?

In a Rushton turbine, the flow is discharged radially outward towards the vessel wall. Half of the flow is directed upwards while the other half is directed downwards, facilitating effective mixing and circulation within the vessel.

What are the primary benefits of using a Rushton turbine?

The primary benefits of the Rushton turbine include its stability during operation, effective mixing capabilities for various fluid types, and its ability to handle gas dispersion. These features make it an ideal choice for many industrial applications.

Can the Rushton turbine handle both fluids and gases?

Yes, the Rushton turbine is designed to handle both fluids and gases efficiently. Its innovative shape and flow dynamics allow for effective mixing in applications that involve diverse phases, maintaining stability and performance throughout the process.

Where can I find more information or videos about Rushton turbines?

More information and videos about Rushton turbines can be found on the dedicated website section that includes various videos demonstrating their function and application. Explore these resources for a deeper understanding and visual representation of the turbine’s capabilities.

Contact our specialized team for all your questions

Tom Pruymboom

Sales Director

Area Worldwide

Bart Brouwer

Area Sales Manager

Area Worldwide

More Rushton Videos

Rushton Articles

Tutorial: Rushton Turbine vs Concave Turbine

We are happy to announce on behalf of Jongia Mixing Technology that we have just launched a new tutorial on our website! This time, we take you into the world of mixing technology with an in-depth comparison between the “Rusthon

Fermentation & Bioreactor Mixing Process

Bioreactors and Fermenters are culture systems to produce cells or organisms. They are used in various applications, including basic research and development, and the manufacturing of biopharmaceuticals, food and food additives, chemicals, and other products. A broad range of cell types and organisms can be cultivated in bioreactors and Fermenters, including cells (like mammalian cell lines, insect cells, and stem cells), microorganisms (like bacteria, yeasts, and fungi), as well as plant cells and algae. The words “Bioreactor” and “Fermenter” are basically the same thing.

Meet Jongia’s Rushton Turbine for Gas-Liquid & Fermentation process applications

The Rushton disc turbine or Rushton turbine is a radial flow impeller used for many mixing applications and particularly for Gas Dispersion and Fermentation applications in process engineering and was invented by John Henry Rushton.[1] The design of the Rushton

Related Articles

The Double Acting Axial Flow Turbine type AST-MTE mixing element

Operation of an AST-MTE Element Operation of an AST-MTE Element This element can be used in both CW (clockwise) and CCW (counterclockwise) directions. In one case, the inner AST element is downward-pumping with the outer tips pumping upward, and in

High-Speed Disperser Technology: The Engineering Behind Effective Mixing

A Technical Guide by Jongia Mixing Technology Core Function High-speed dispersers excel at three critical tasks: Fracturing powder agglomerates into fine particles Creating uniform powder distribution throughout liquid mediums Facilitating complete dissolution of soluble materials Operating Principles High-speed dispersers transform

VVTI Biogas Tilburg

VTTI Biogas Tilburg is developing a new bio-energy facility, focusing on processing organic waste. The plant is expected to produce approximately 23 million cubic metres of biogas annually. A portion of this will be converted into green gas for the