Special Agitators

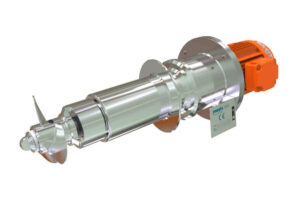

Magnetic Mixer

Magitator – Magnetic Mixer for Pharma, Food & Chemical industry

Opting for the Magitator ensures that the tank can remain hermetically closed under highly sanitary conditions. The open design of the mixing head ensures an optimum flow for easy cleaning and efficient mixing. The cleanability of the magitator is compliant with the most stringent CIP and SIP requirements. Zero-emission is ensured and in addition the absence of a mechanical seal considerably cuts down on maintenance costs.

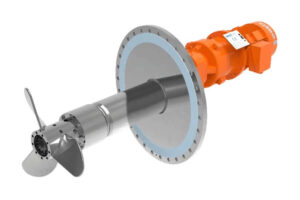

In-line Mixers

Types: FTD, JDR, L

Our in-line mixers offer a high mixing efficiency at low operating cost. They are available in a great variety of construction types and can be connected in many possible ways. Besides, the Jongia in-line mixers can be constructed in various types of materials, such as stainless steel, carbon steel, etc. Advantages:

- Continuous process stream

- Short residence times

- A high reliability

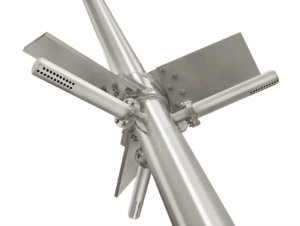

Gas Inducing Mixer

Jongia meets the challenge of modern-day high productivity requirements with its novel gas-inducing system. In a reactor a gas-inducing coil, the so-called sparger, is installed for the primary gas supply. The unused gas is collected in the head space of the reactor above the liquid level. This gas is recirculated through the hollow shaft and re-induced through the gas inductors mounted below the liquid level.

Conical Helix Mixer

Jongia’s CCM for solid products was developed under the guidance of our sister company BOLZ-SUMMIX, a leading manufacturer of machinery and systems solutions in the fields of mixing and drying, mainly in conical vessels. The new development is intended to be used for products demanding lower mixing accuracy and a simplified agitation system than that of the conventional cone-screw mixer/dryer with independent twin-shaft rotation of orbit arm and mixing screw.

We now can offer our clients an alternative specifically with respect to better mixing efficiency and shorter process times compared to other industrial single or double ribbon systems. The machines can be supplied with working volumes from 50 to 11.000 liters in a variety of materials.

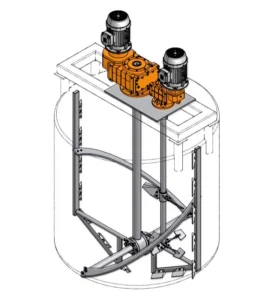

Counter rotating mixer

Types: CRM Mixer, Dual Mixing System

A combined process? Jongia’s combination mixers (type CRM or dual mixing system) are ideal in a process that requires the mixer to perform more than one specific duty.

Depending on the requirements, a vessel can be fitted with two or more separate mixers. A wide range of combinations is possible. A commonly used solution is an anchor type mixer with an axial flow type, a dispersion disc or a propeller type mixer.

Frequently Asked Questions

What types of special agitators do you offer?

We offer special agitators tailored for various industries, including food, chemicals, pharmaceuticals, and bio-based applications. Each type is designed to meet the specific needs of unique processes, ensuring efficiency and effectiveness in diverse operational environments.

What is the Magitator?

The Magitator is a magnetic mixer ideal for the pharma, food, and chemical industries. It keeps the tank hermetically sealed and compliant with strict cleaning standards. Its design ensures optimal flow, easy cleaning, and significantly reduces maintenance costs through the absence of mechanical seals.

What are the advantages of in-line mixers?

Jongia’s in-line mixers provide high mixing efficiency at low operating costs. They can be configured in various ways and made from multiple materials, ensuring reliability and continuous processing with short residence times, making them versatile for different applications.

Can you explain the gas-inducing mixer system?

Our gas-inducing mixer utilizes a sparger for primary gas supply, collecting unused gas in the reactor’s headspace. This gas is recirculated through the hollow shaft and reintroduced below the liquid level, enhancing productivity in modern mixing processes.

What is the purpose of the counter-rotating mixer?

The counter-rotating mixer, also known as the CRM or dual mixing system, is designed for processes needing multiple mixing functions. It enables the combination of different mixers in a single vessel, offering flexibility for achieving various mixing goals effectively.

Contact our specialized team for all your questions

Tom Pruymboom

Sales Director

Area Worldwide