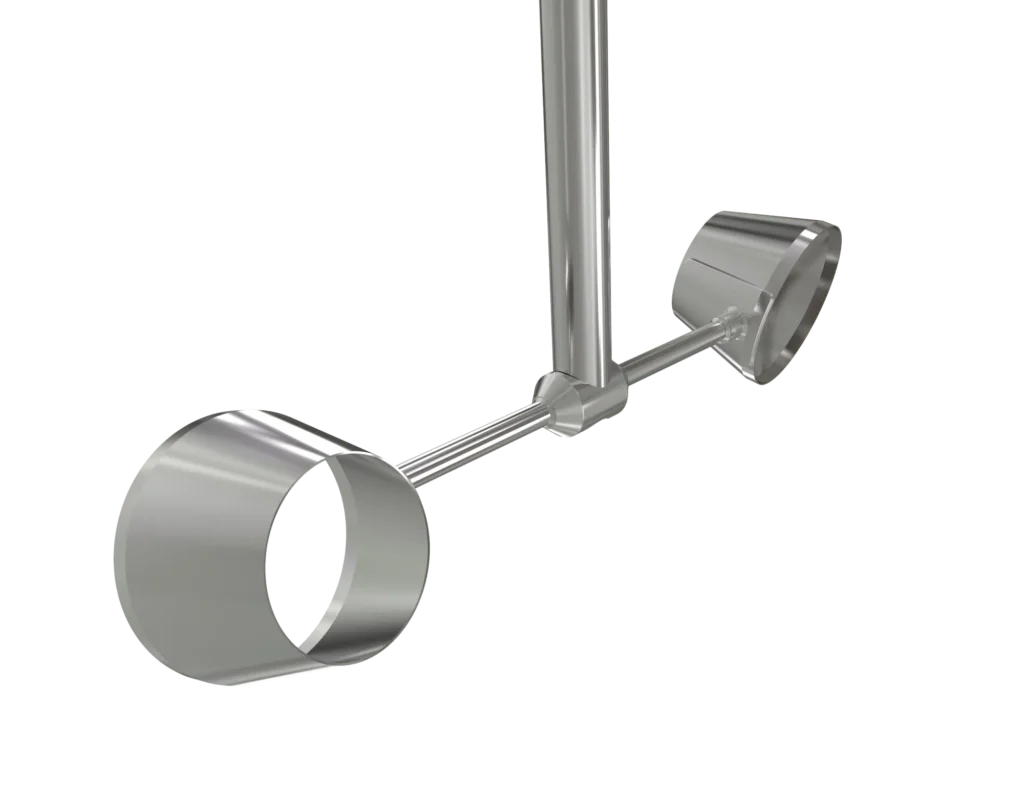

The cupmixer is a stirring element that can be widely deployed. It can therefore be used in a variety of industries. Nevertheless, a cupmixer is primarily used for mixing products for which it is important that no air is entrapped and that homogenous quality is maintained. But at what point in the customer’s application process does Jongia Mixing Technology actually opt for the use of a cupmixer?

Advice after thorough investigation

After the first contact with the customer has taken place, in which the problem, or the request, has been revealed, Jongia Mixing Technology starts to investigate which stirring element is most suitable. Jongia Mixing Technology first asks the customer and itself a number of important questions, so no immediate advice on a stirring element is given. For instance, what type of product are we dealing with? What is the customer’s problem and what are the different requirements and starting standards? Next, Jongia Mixing Technology examines what the corresponding viscosities and densities are. But also the other product properties and rheology (flow characteristic of the product) are examined. Based on this information the best suitable stirring element is determined.

Cupmixer is widely applicable

Because Jongia Mixing Technology is market leader in the Benelux, many companies know how to find Jongia Mixing Technology when they are looking for a stirring element for their mixing process. One of these companies is one that keeps living larvae homogeneous in water. They approached Jongia Mixing Technology to ask whether there was a product-friendly agitator that could also guarantee the right process result without damaging the contents. After many questions back and forth, Jongia Mixing Technology built a test stand, to scale, and used the cupmixer with an additional stirring element that provided pumping from the top for the desired result.

USP’s cupmixer of great value

Customers who mix products into end products do not always have sufficient knowledge of the possibilities of the various agitators. It has happened that a customer, even after an extensive report from Jongia Mixing Technology, did not believe in the power of the cupmixer. The customer was therefore invited to experience the difference between two different stirring elements. By making a test setup in which the customer’s product was mixed by two different stirring elements, of which one version was the cupmixer, this customer was convinced of the cupmixer in no time and subsequently used these stirrers in their mixing process.

Want to know more?

The process from request to solution is always specified per customer. Jongia Mixing Technology has the knowledge and experience to give you broad advice in this field. Do you have any questions? Please do not hesitate to contact us.

Want to know more?

As with all production processes, mixing the various products requires a specific approach and an appropriate agitator. Jongia Mixing Technology has the knowledge and experience to give you comprehensive advice in this field. Do you have any questions about the BioFoil® propeller or any other agitator? Please do not hesitate to contact us.

Contact our specialized team for all your questions

Tom Pruymboom

Sales Director

Teun van der Spek

Area Sales Manager

Technical Questions?

Sijko van der Veen

Application Engineer

Technical Specialist

Tutorial: Batch Crystallization

Jongia Mixing Technology has initiated countless mixing processes all over the world with the help of her agitators. In a number of these mixing processes, crystallization is of great importance to obtain the desired final product. In this tutorial, Area

The cupmixer: from request to solution

The cupmixer is a stirring element that can be widely deployed. It can therefore be used in a variety of industries. Nevertheless, a cupmixer is primarily used for mixing products for which it is important that no air is entrapped and that homogenous quality

Tutorial: How does the cupmixer work?

The cupmixer is a special stirring element. It is used in the mixing process of viscous products. The cupmixer is also suited for sensitive viscous products that are easily damaged. A cupmixer is placed in the tank horizontally and can